AI and Robotics: The Future of Automation

The powerful fusion of AI and robotics is transforming the capabilities of automation solutions. As AI technology continues to evolve, its integration enables robotics to become more autonomous, flexible, and capable of handling complex tasks with minimal human-robot interaction. AI fully supports smarter, more adaptive systems that enhance efficiency and strategic decision-making, vital for agility and long-term growth.

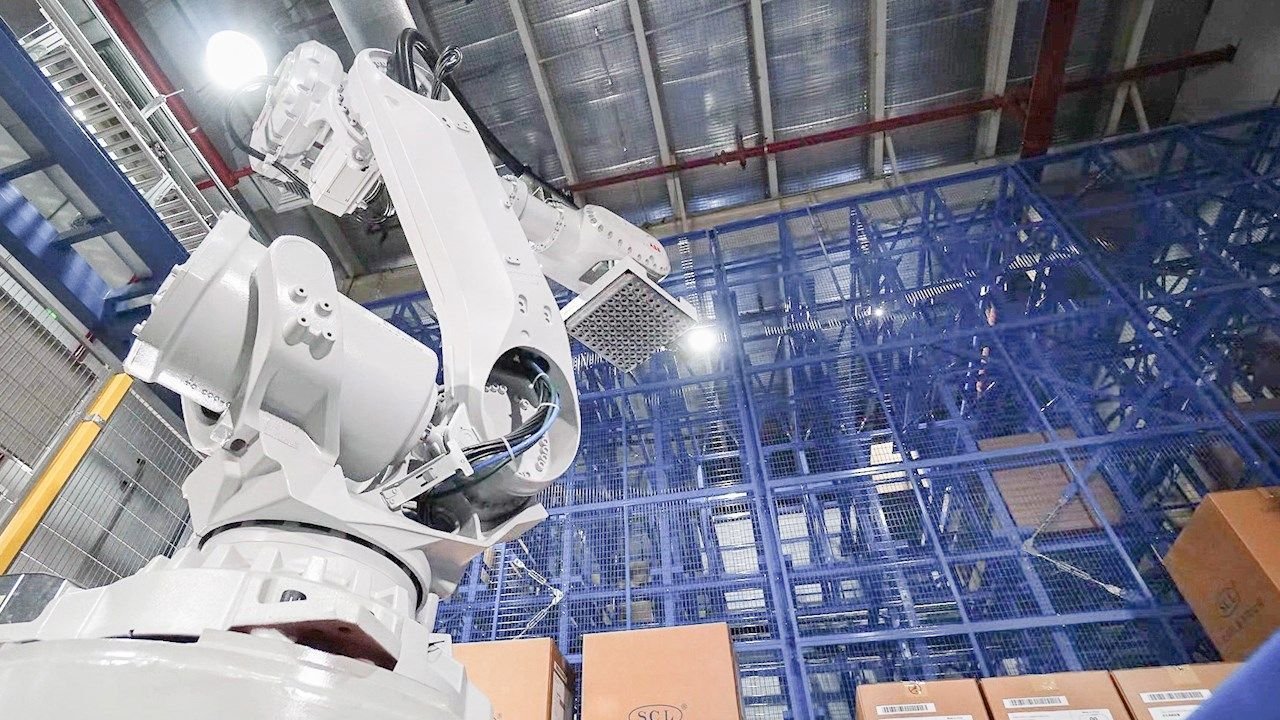

As automation moves toward greater autonomy, autonomous systems powered by robotic automation algorithms and edge computing will redefine what robotics can achieve. Factories are already adopting robotic cleaning systems, robotic process automation, and digital automation platforms that merge software and hardware for end-to-end optimisation. In warehousing and logistics, mobile robotic systems, supported by vision inspection automation and goods-to-person technologies, are enabling faster throughput while warehouse drones and RS for boxes drive efficiency in distribution. These innovations point to a future where collaborative robotic systems and AI-driven robotic automation systems transform entire supply chains into flexible, intelligent, and highly connected networks.

The Role of AI-Powered Robotic Automation

AI-driven robotics enhances warehouse automation by enabling the machines to understand, learn, and adapt to their environments. Unlike traditional robots that are designed to follow pre-programmed instructions, AI-powered robots use advanced computer vision, natural language processing, and real-time data analysis to perform tasks with greater accuracy and flexibility. Across industry operations, AI-driven robots are highly effective at optimising workflows, reducing errors, and improving decision-making. This is a key aspect of digital and robotics integration and smart manufacturing.

How Machine Learning Optimises Robotic Performance

Machine learning algorithms allow robots to continuously improve their performance by analysing vast quantities of data from sensors, cameras, and past operations. The ability for self-learning enables robots to refine movements, detect anomalies or discrepancies, and optimise operational processes over time. In predictive maintenance, for example, machine learning helps robots anticipate equipment failures, ensuring proactive repairs and minimising downtime. This adaptability makes robotic automation more efficient, reducing costs and enhancing productivity across industries. This is fundamental to robot learning and adaptive capabilities.