What Are Collaborative Robots?

Collaborative robots, often called cobots, are a type of industrial robot specifically designed to work safely alongside human workers in a shared workspace. Unlike traditional robotic systems that require cages, safety barriers, or separation from the human workforce, cobots use advanced sensor technology, artificial intelligence, and control algorithms to detect human presence, adjust their speed, and prevent collisions in real time. Their purpose is to support people by automating repetitive, strenuous, or precision-based tasks, while maintaining strict safety protocols and meeting international safety standards.

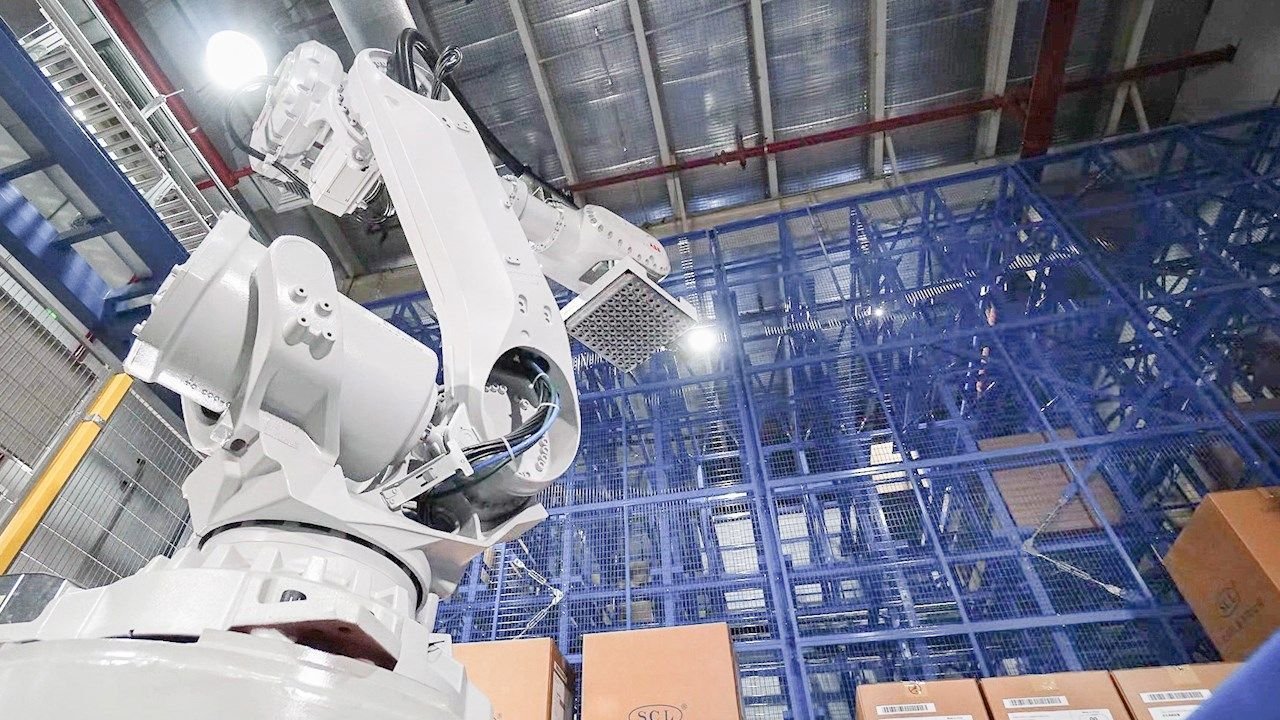

Cobots are lightweight, flexible, and easy to program, making them suitable for both large-scale factories and SMEs. They are widely adopted in manufacturing environments, including the automotive, electronics, food, and aircraft industries, where they perform tasks such as assembly line operations, welding cobots, machine tending, palletising, packaging, and quality control. As part of the shift towards Industry 5.0, cobots combine the efficiency of automation with human creativity, ensuring productivity gains while enhancing workplace safety.