Robotics Matters, But Integration Matters More

In today’s competitive landscape, operational agility is as crucial as operational efficiency. Robotics offers a solid and reliable pathway to achieve both, but only when deployed with strategic intent.

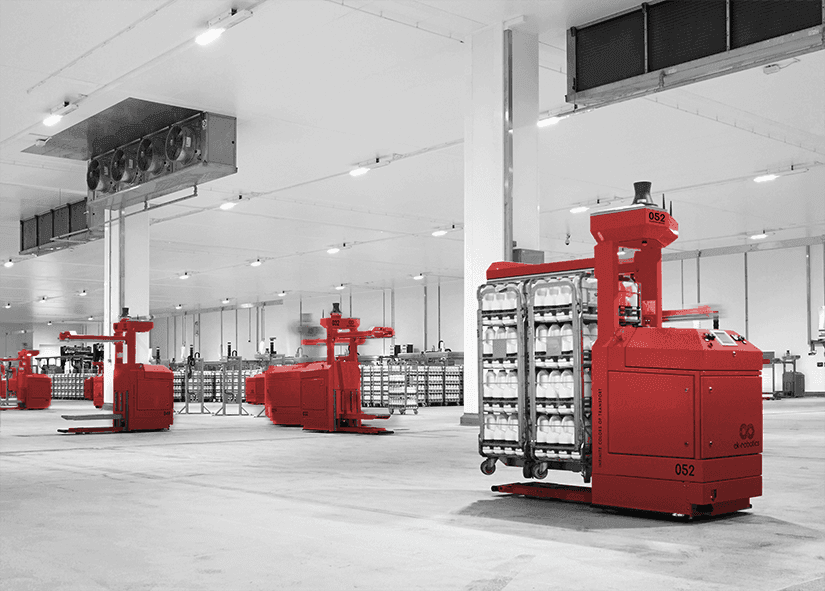

Consider a high-throughput grocery distribution centre implementing AMRs to automate the transport of goods using totes. Without proper integration into the warehouse management system, the robots might underperform or create bottlenecks. A robotics integration specialist ensures a seamless flow of goods, analysis of data for real-time visibility and optimised routing, and synchronisation with picking systems and other processes, delivering a complete solution that works holistically.

Similarly, on a food manufacturing line using vision-guided pick and place robots, the precision of the robotic movement must be harmonised with other integrated processes, such as conveyor speeds and real-time quality control. An integrator’s experience ensures that all elements combine to deliver a seamless and efficient solution for operational requirements.