Types of Storage Solutions in Cold Chain Logistics

To maintain temperature integrity, cold chain operators can choose from several types of specialised cold storage facility systems, ideally suited for cold and frozen applications:

Refrigerated Warehouses: Facilities with large-scale refrigeration systems divided into temperature zones.

Walk-in Cold Rooms/Freezers: Common in smaller operations or at final distribution points.

Blast Freezers: Rapidly bring product temperatures to freezing.

Insulated Containers and Pallet Shippers: Used in transit to maintain temperatures.

Mobile Cold Storage Units: For temporary or remote applications.

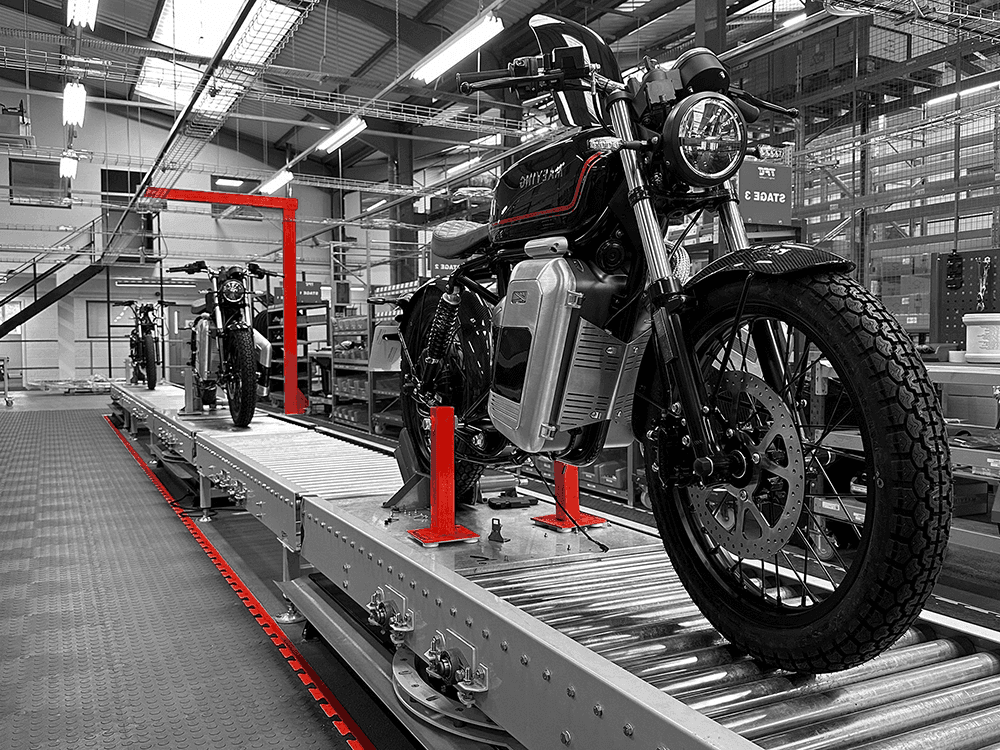

Regardless of the chosen storage system, robotic systems offer a robust and reliable solution to automate part, or all of the logistics process for optimised efficiency, accuracy, and safety in temperature-controlled warehouses.

Types of Robots Used in Cold Chain Logistics

There are various forms of robotics that are widely used in cold chain logistics operations, each with distinctive benefits. The most common include:

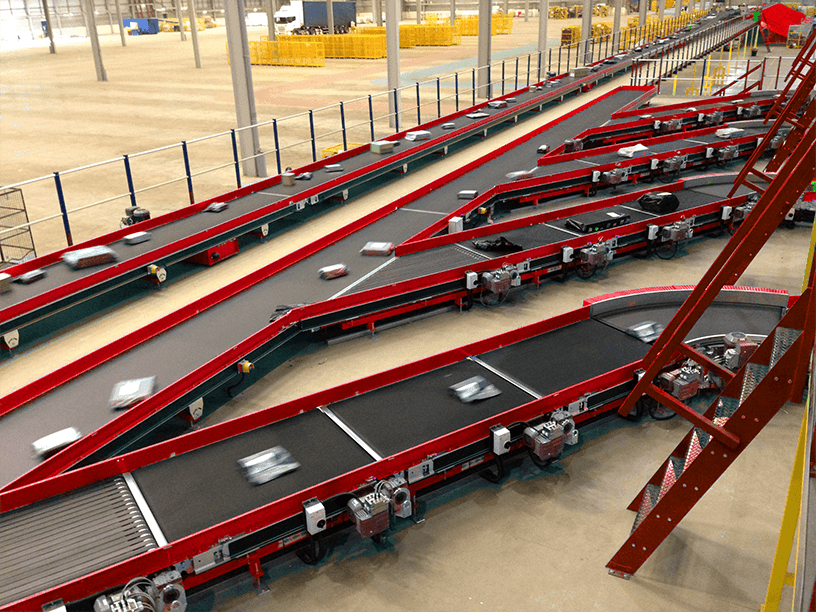

Autonomous Mobile Robots (AMRs): Used for a wide range of intralogistics applications, order picking, and transporting cartons or bins from storage to packing stations. AMRs use cold-rated batteries (lithium-based) and LiDAR and camera-based navigation that functions in low-visibility or frosted environments, offering a compact footprint for high-density storage.

Automated Guided Vehicles (AGVs): Manage the movement of pallets or totes between cold docks, staging areas, and cold rooms. With floor-guided or magnet-based navigation, AGVs are capable of operating at -25°C or lower, reducing the need for forklift drivers in harsh cold storage environments.

Robotic Picking Arms: Ideally suited to piece-picking for e-commerce, pharmaceuticals, or high-turnover SKUs in grocery. These collaborative robots use grippers or suction customised for chilled or frozen packaging. They are integrated with computer vision and artificial intelligence for item identification and function well in cold environments with condensation-resistant components.

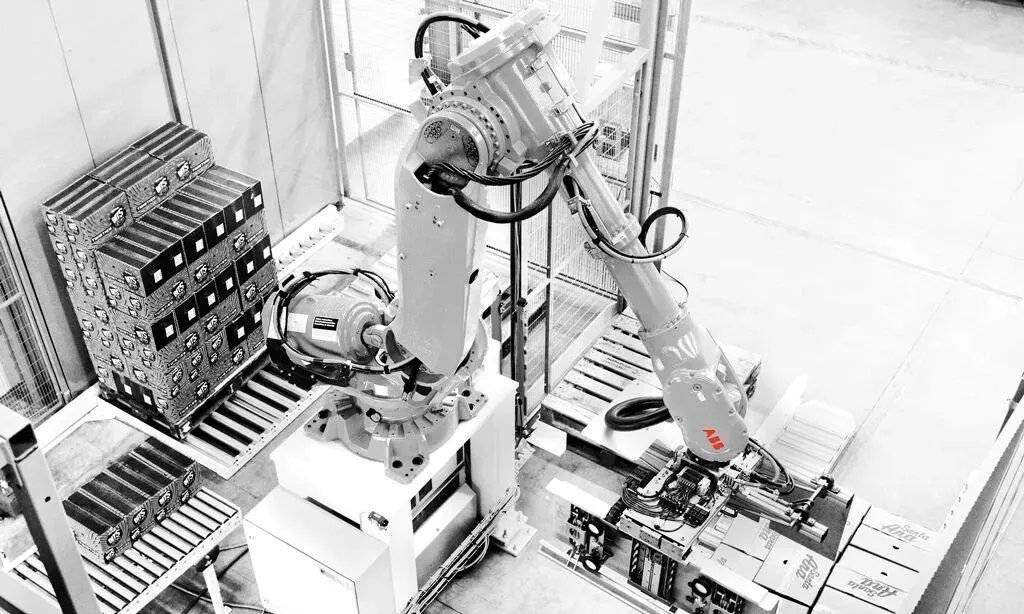

Palletising/Depalletising Robots: Used to automate the process of stacking or unstacking crates, trays, or cartons. Palletisers feature heavy-duty and cold-hardened mechanical arms, offering 24/7 operation to support high-throughput fulfilment centres and cold storage warehouses.

Inspection and Monitoring Robots: Used for surveillance, environmental monitoring, and predictive maintenance. Equipped with thermal sensors, cameras, and environmental probes, inspection robots can navigate narrow aisles and high racking structures to collect valuable product data, enhancing warehouse control and reducing the risk of human exposure.

Examples of Industry Applications

Robotic automation is transforming cold chain operations across a range of industries. In the Food & Beverage sector, robotic palletising of frozen meats and the use of autonomous mobile robots (AMRs) to transport chilled goods to packing stations improve both efficiency and product handling. In Pharmaceuticals, robotic arms are used to pick individual doses, while automated guided vehicles (AGVs) manage the movement of temperature-sensitive items such as insulin and vaccine pallets under strict thermal control. The Retail & Grocery industry benefits from AMRs and robotic arms fulfilling online chilled food orders in micro-fulfilment centres, streamlining last-mile logistics. Meanwhile, Logistics 3PLs deploy automated storage and retrieval systems (AS/RS) with robotic cranes and shuttles for high-density frozen storage in fully automated cold chain warehouses. These robotic solutions offer precision, speed, and enhanced safety in temperature-critical environments.