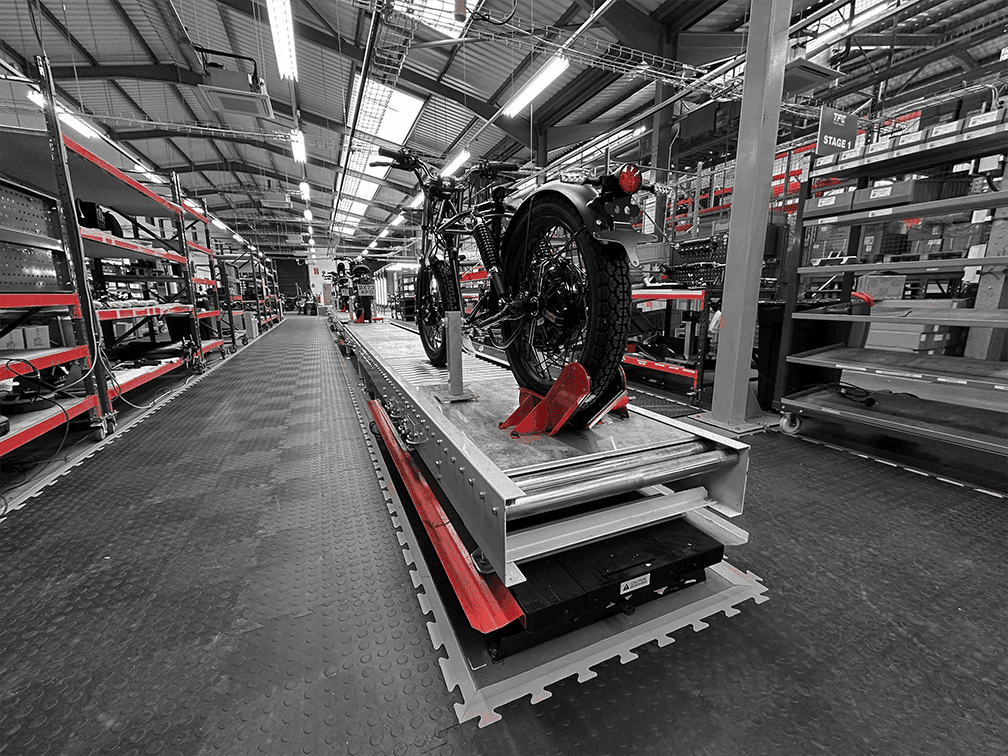

A conveyor system is commonly used in the mining, automotive, agricultural, food and beverage, bottling, manufacturing, warehouse and logistics, and packaging industries

All sorts of materials are conveyed thanks to the different conveyor belts you can get to manage different loads and materials. Some of the common items that are used by conveyors are food items such as beans, nuts, canned foods, and vegetables, bottles, canned drinks, automotive parts such as engines, car frames, and tyres, pills such as medicine or supplements, large amounts of powder, furniture, and much more.

Whether you need a conveyor system and what conveyor you need depends on what you require of the system and therefore you need to outline how the conveyor system will be used beforehand. These factors include what it will be transporting, loads of that item(s), the speed of the conveyor, how much it needs to accumulate at a time, how long it takes to sort the items, where the pickup points are, the widths and lengths, and in cases many more factors to ensure it meets your businesses desired outcomes.

Maintaining a Conveyor System

As useful as conveyor systems can be, they do need to be maintained for the conveyor system to run effectively or just like any electrical item they can break and be costly to replace, both in time and in money if a big system has a bespoke design.

Businesses should make looking after their conveyor systems a priority to ensure no loss of business or disruption to their manufacturing, packaging, or delivery process. You can, of course, analyse the running of your system through a human-machine interface (HMI) which allows you to analyse and monitor previous and real-time data.

Certain aspects to ensure that they work at optimum capacities such as regular inspections, system audits, close monitoring of motors, ensuring spares are in stock for changeovers should be looked at. Also, ensuring that the operational team are trained on running the system and are aware of what to look for when identifying errors or problems is necessary.

There are ways you can increase a conveyor’s life or the system cycles they run by choosing the right conveyor type when installing the system, making sure the system is designed to fit the layout or goes through the correct areas at optimum speed, and ensuring the system is regularly maintained.

Depending on the conveyor system installed there will be different functional problems you’ll have to watch out for. A roller conveyor used for moving parcels is going to need different maintenance to an overhead chain conveyor moving car frames or a belt conveyor moving high amounts of papers compared to a pallet conveyor moving heavy loads of goods.

Again, if the conveyor is being used in harsher conditions such as in below-freezing temperatures there will be different maintenance procedures to ensure optimum running.

It’s recommended to have the approach of preventive maintenance over reactive maintenance, this way you can stop your conveyor or motor from getting to a point where it’s damaged which could result in further damage down the line. Doing preventative maintenance allows you to schedule sorting the system at intervals with a likely lower cost than waiting for the system to break and then having additional downtime of the whole system which could be in peak time.

Materials Used in a Conveyor System for Impact and Wear Resistance

Conveyor systems need to be resistant to impact and wear due to the high volume of items they’re moving that can be sharp and heavy and not be seized up due to deformation.

The handling materials that these systems use include UHMW, nylon, Nylatron NSM, HDPE, Tivar, Tivar ESd, and polyurethane. The handling material used will depend on the function of the conveyor and where static control is a factor, the conveyor system will need special materials to be designed to either dissipate or conduct electrical charges from the conveyor.