Our commitment to providing cost-effective and space-saving solutions is evident in our use of mobile robots and compact robotic palletising systems. These systems are designed to operate at faster speeds, optimising floor space and handling varying quantities of inventory efficiently. With the ability to implement both slow and high-speed operations, our solutions cater to different production demands, ensuring that fresh pallets are always ready for shipment. By integrating our automated palletising solutions with your existing production lines, we help streamline your operations, reduce manual labor, and significantly improve overall productivity.

Intelligent Robotic Palletising with Advanced Automation Tools

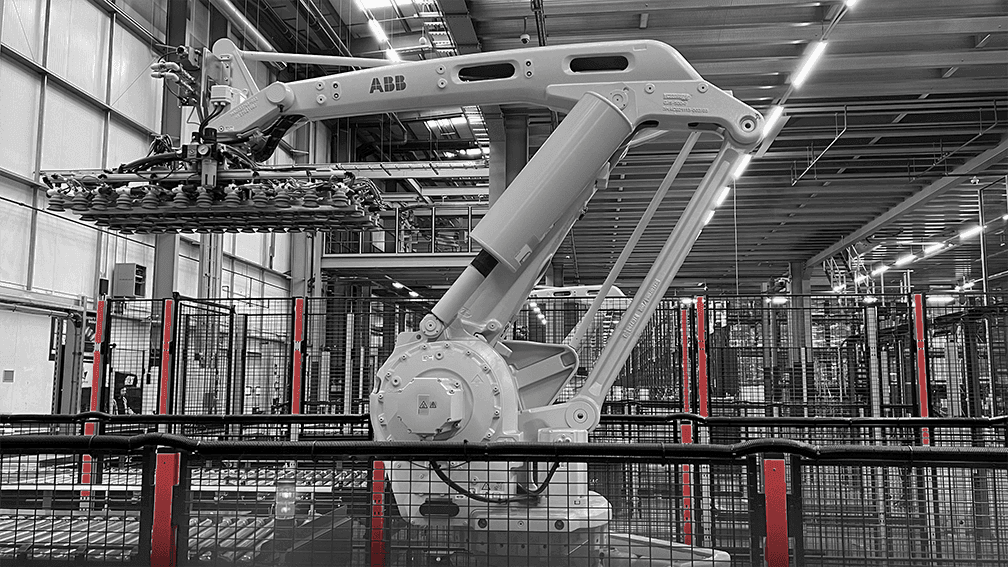

Our robotic palletising systems combine cutting-edge robotic automation with practical engineering to deliver reliable, high-speed performance. Featuring robotic arms, articulated arm configurations, and collaborative options such as the Cobot palletiser, we offer full flexibility for both high- and low-volume operations. Each system is built around a modular palletiser system, with integration-ready components such as pallet conveyors, pallet dispensers, and pallet sensors to ensure seamless flow across your production lines.

Precision and adaptability lie at the heart of every installation. Whether using a vacuum gripper, suction pad, magnetic grippers, or tailored gripping elements, our bespoke end effector designs ensure accurate placement regardless of product shape, size, or weight. Combined with vision systems and machine vision automation, these tools allow our robots to identify, orientate, and stack with remarkable accuracy—even for complex mixed-case scenarios.

Our robotic palletising cells also feature intelligent software such as Auto-Pallet Patterns, enabling each system to calculate the optimal pallet pattern for stability, height limits, and transport safety. From standardised box sizes to irregular SKUs, each pallet is built to maximise stacking efficiency and meet the exact pallet height requirements of your operation. For facilities seeking smart, scalable automation, we offer full integration with Automated Guided Vehicles (AGVs), robotic wrapping systems, and central palletising solutions. These elements extend your automation beyond the palletising cell, creating an end-to-end workflow that enhances production rates while reducing manual handling and labour overhead.

All systems are manufactured using industrial-grade materials including stainless steel, making them suitable for heavy-duty industrial environments and hygienic sectors such as food and beverage. Each solution is developed with adaptability in mind—ready to support a range of pallet handling options, including single SKU lines, mixed case pallets, and dynamic SKU switching. Whether you’re investing in a full Cobot Palletising Solution or upgrading an existing palletiser system, our experienced team ensures a smooth deployment with tailored support, simulation tools, and scalable architecture that evolves with your production goals.

Every robotic palletiser we deliver is supported by intelligent Palletising Software that communicates directly with the robot’s control system, providing operators with a central interface for configuration and oversight. Through intuitive Robot Programming functions, operators can modify pallet patterns, run diagnostics, and adapt to new packaging types or pallet formats on the fly. This integration ensures high pallet loading accuracy and consistent throughput across all product handling operations. When paired with automated pallet handling equipment such as pallet dispensers and conveyors, the system forms a connected, data-driven workflow designed for precision, flexibility, and future scalability.

As a trusted automation partner within the palletising industry, L-A-C delivers solutions that combine robotics, Smart Conveyor systems, and real-time data connectivity. Integration with management information systems and warehouse management systems allows businesses to track performance, monitor throughput, and optimise maintenance planning. Our expertise in precision product handling, innovative end-of-arm tooling, and adaptable case packing systems ensures complete control across every packaging line, helping clients achieve operational excellence while maximising space and energy efficiency.