Collaborative Robots (Cobots)

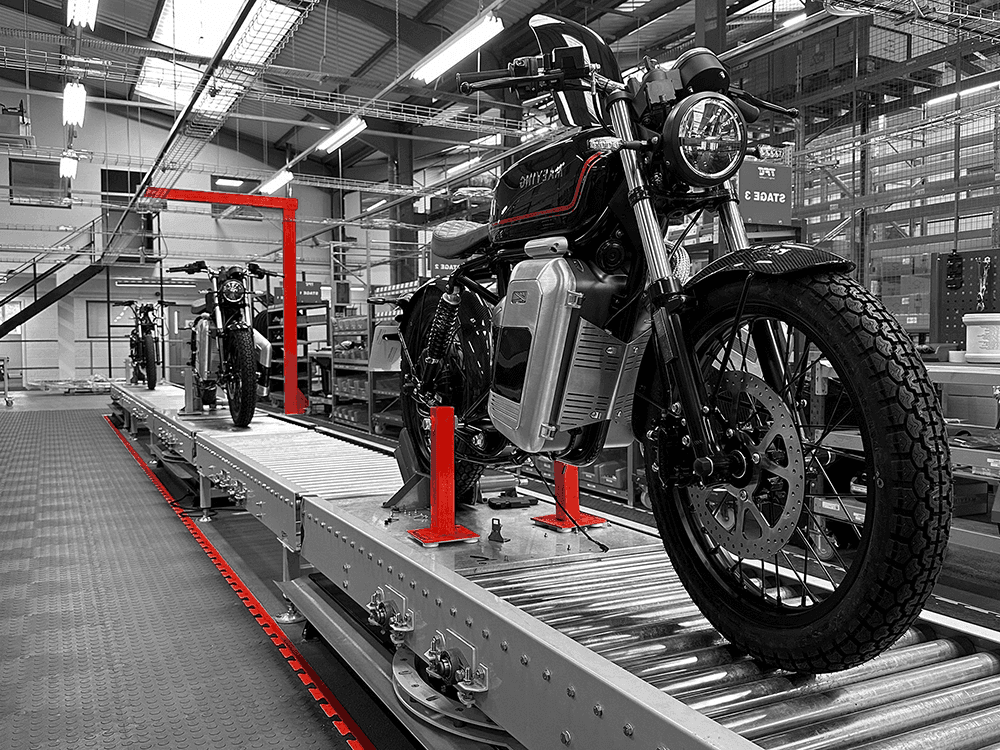

Among the most impactful innovations in warehouse robotics are collaborative robots, or cobots. These are specifically designed to operate in close proximity to human workers without the need for protective barriers. Unlike traditional industrial robots, cobots help with repetitive and ergonomically challenging tasks and improve accuracy across warehouse operations.

By working alongside human teams, cobots reduce physical strain and boost warehouse productivity. They also help workers focus on high-value tasks while robots take over routine activities, supported by warehouse management software that provides real-time scheduling and task allocation.

Designing for Safety: Built-In Features of Modern Robotics

Modern warehouse robots are equipped with embedded safety features to prevent accidents and minimise risks:

- Advanced Sensors: Including LiDAR, infrared, ultrasonic, and Advanced Vision systems, these enable real-time obstacle detection.

- Speed and Force Limitation: Many robots are programmed to slow or stop entirely when near a person.

- Emergency Stop Functions: Accessible controls allow immediate shutdown in case of risk.

- Predictive Maintenance Alerts: Inbuilt systems monitor for issues that could cause mechanical failure.

- Fail-Safe Systems: Backup protocols ensure operational safety in the event of system error.

These features reflect the growing commitment to safety by design, where technology is created with risk prevention built in from the start.