Building Flexible and Future-Proof Robotic Systems

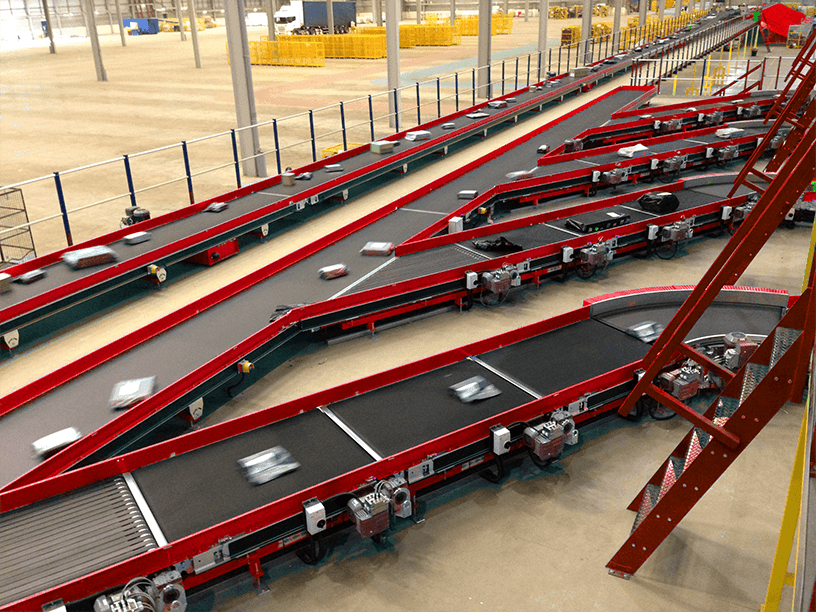

As global supply chains demand more agility, flexible automation has become a strategic priority. This shift means robots must operate in dynamic environments with changing tasks, layouts, and product lines.

Emerging solutions include:

- Autonomous robots and autonomous mobile robots (AMRs) capable of navigating complex spaces

- Mobile manipulators that combine mobility with industrial robot arms for advanced handling

- Reconfigurable robot applications and modular designs to adapt to new workflows

- Robotic Process Automation (RPA) for digitising back-end manufacturing tasks

These systems support on-demand production and enable smaller manufacturing facilities to scale operations without heavy capital investment.

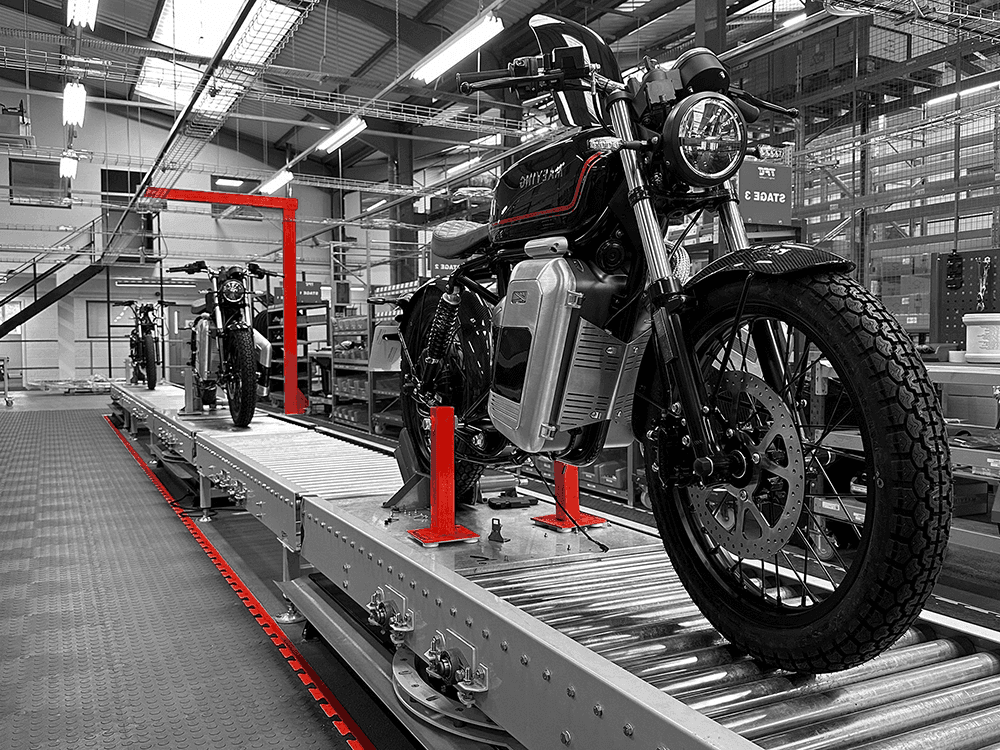

Human-Robot Collaboration and Workforce Transformation

The future of manufacturing will be defined not just by robots, but by how people work with them. Human-robot collaboration opens new possibilities for shared tasks, allowing operators to focus on value-added roles while robots handle repetitive or high-risk functions.

In this environment:

- Cobots enhance safety and efficiency in manual assembly lines

- AI-enhanced robot programming tools reduce setup time and training needs

- Agility Robotics and other shape-shifting robots are being explored for adaptive, task-specific support

This transformation is not about replacing human workers but augmenting their capabilities and improving workplace safety.