Types of Vertical Conveyor Systems and Their Benefits

There are several types of vertical conveyor systems available for small, medium and large-scale operations, each tailored to specific applications, loads, and throughput requirements.

Vertical Reciprocating Conveyors (VRCs)

Vertical reciprocating conveyors are essentially material lifts that move goods between floors using a reciprocating motion: a repetitive, back-and-forth or up-and-down movement along a straight line. VRCs can be custom-built to any height and typically transport palletised loads, totes, and cartons with a load capacity ranging from 100 kg to several tonnes. Their modular design supports compact design requirements and allows for minimal maintenance. They are more cost-effective compared to freight lifts, offer a space-saving solution particularly suited to mezzanine access, and integrate easily with Roller Conveyors and other types of conveyor systems. Vertical reciprocating conveyors are commonly found in warehouses, retail operations, and manufacturing facilities handling heavy pallets and bulky loads.

Continuous Vertical Conveyors (CVCs)

Continuous Vertical Conveyors move products in a continuous loop, typically using slats or trays attached to a chain conveyor or belt system. CVCs offer a high-speed, uninterrupted flow of material, transporting goods up or down simultaneously with a minimal floor footprint. Continuous vertical conveyors provide a high level of throughput, safe handling of fragile or gentle product types, and are low maintenance due to fewer moving parts. Safety features such as safety sensors ensure compliance with safety standards. CVCs are widely used in e-commerce fulfilment, food and beverage processing, and applications with load capacity needs.

Spiral Conveyors

Spiral Vertical Conveyors are designed to move products along a helical path, combining vertical transport with accumulation to reduce the potential for bottlenecks. They are compact in design, taking up minimal horizontal space, can handle continuous or intermittent flow of material, and are available in belt or roller configurations. This conveyor product vertical supports a wide variety of product sizes, ideal for automated production lines and packaging areas. Spiral conveyors are suited for assembly operations in tight warehouse environments and are commonly used for packaging lines, bottling plants, and food production facilities.

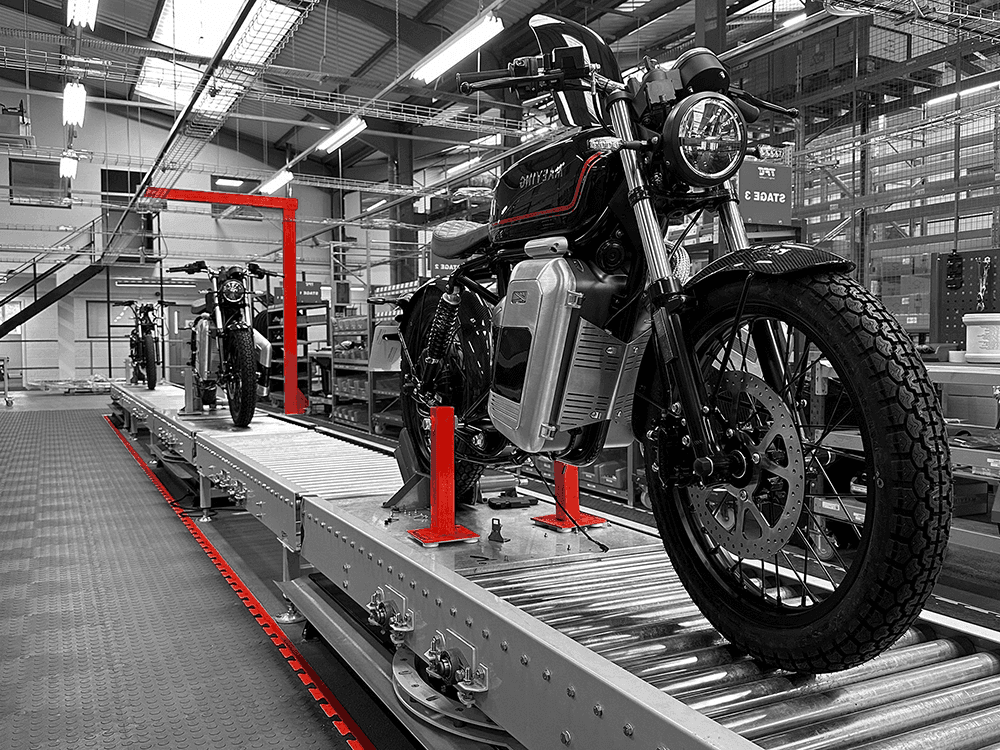

Vertical Lifts (Pallet Lifts and Tray Lifts)

These systems move goods vertically using motorised shuttles or robotic mechanisms. They are typically used in advanced production lines such as Automated Pallet Shuttle systems and support integration with Warehouse Management Systems. Vertical lifts are ideally suited for high-density, high-value operations, providing seamless automation integration with robotics and shuttle systems to enhance order accuracy, speed, and precision. Their drive motor systems ensure accurate load transfers with minimal human intervention. They are commonly found in the automotive industry, pharmaceuticals, and electronics distribution.

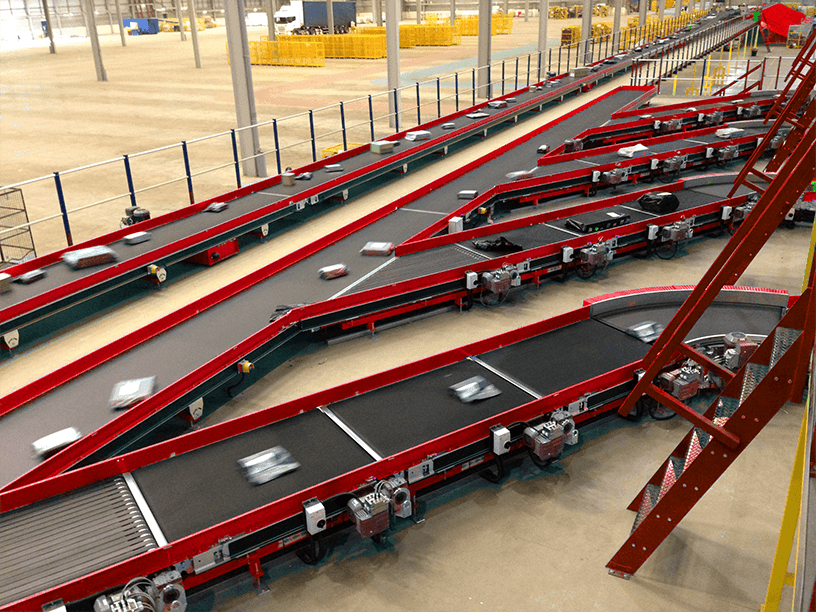

Incline Conveyors

Incline belt conveyors use a sloped belt or roller system to move goods between elevations, commonly used for short vertical transfers. They feature an adjustable incline angle available in flat, cleated or troughed belt options and can be modular in design. Incline conveyors offer a simple and cost-effective option for moderate height changes, helping maintain a safe working environment while transporting heavy loads and a wide product range. Incline conveyors are used in Distribution Centers, sortation depots, and bulk-handling applications requiring moderate elevation change.