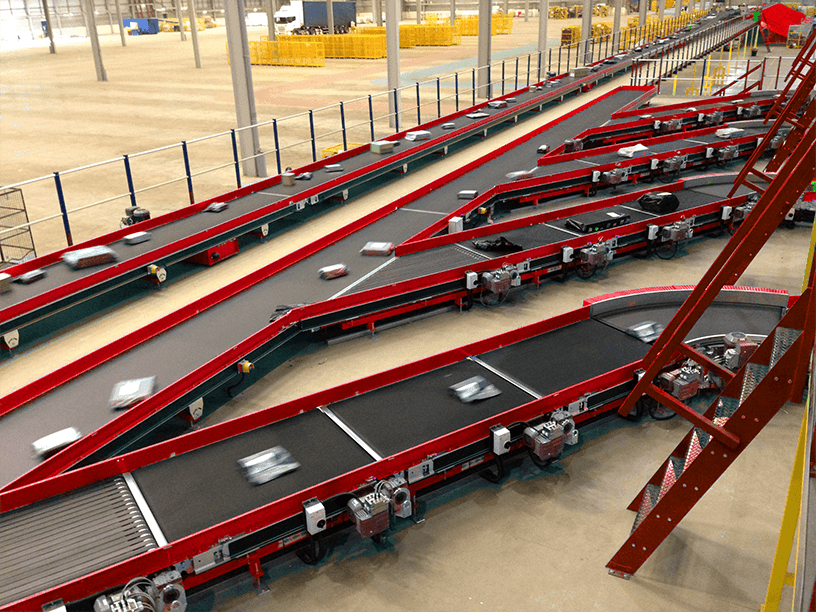

How AMRs Move Goods in Warehouses

Highly adaptable and intelligent, autonomous mobile robots are used in multiple ways to streamline operations by transporting a wide range of goods around the warehouse, including:

Transporting Totes: AMRs move individual totes filled with products to and from picking stations, ensuring seamless order fulfilment. These may also work in combination with taller picking robots designed to retrieve totes from dedicated high-density storage structures. Their integration into the automation solutions landscape offers a more scalable solution for increasing throughput.

Moving Shelves: Some AMRs can lift and transport entire shelving units, optimising warehouse space, improving accessibility, and minimising the risk of injury or accidents through manual handling. These capabilities are essential in complex operations where efficient use of space is critical.

Handling Pallets: Heavy-duty AMRs are specifically designed to transport fully loaded pallets across warehouse floors, reducing the need for forklifts and manual pallet jacks. These solutions not only improve operational efficiency but also address challenges associated with heavy loads in high-volume environments.

By automating the transport of materials, AMRs help warehouses achieve operational excellence and streamline the landscape of warehouse operations.