Types of Conveyor Systems Used in Pharmaceutical Applications

Depending on the application and the type of product being handled, different conveyor technologies are employed, each designed to provide efficient, safe, and consistent movement throughout the various stages from manufacturing to final delivery. Some of the most commonly used conveyors for handling pharmaceutical goods include:

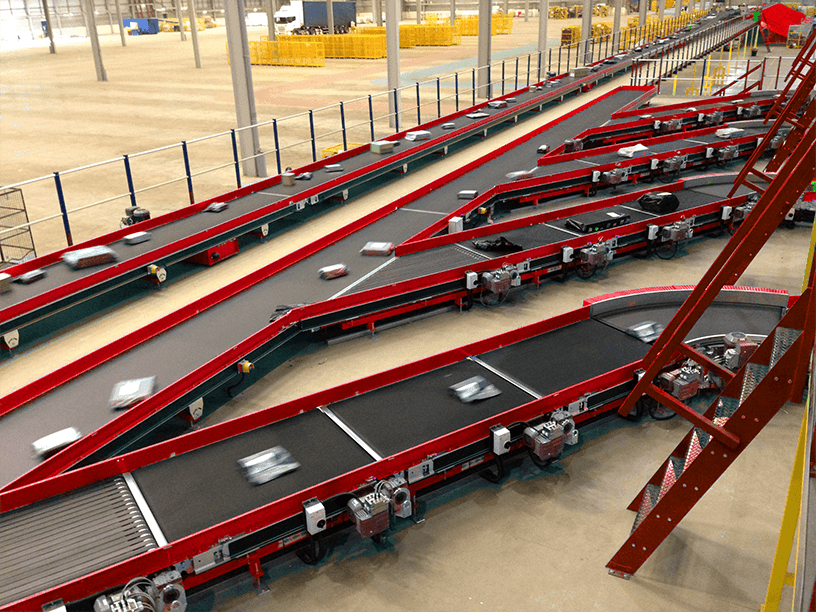

Belt Conveyors - ideal for transporting lightweight, packaged products like blister packs, bottles, and cartons. Belt conveyors offer smooth, stable movement, reducing the risk of product damage. Applications include bottle and blister pack transport, packaging lines, and carton movement in warehouses. Belt conveyors are easy to clean, modular to ensure they can be customised in length & width, and can include accumulation zones.

Modular Plastic Belt Conveyors – this type of conveyor is made from interlocking plastic pieces, providing durability and flexibility, and are particularly useful in wet or cleanroom environments. They are typically used for tablet and capsule transport as well as product accumulation and sorting. Benefits include washable and corrosion-resistant materials, a hygienic design, and quick belt repair and replacement.

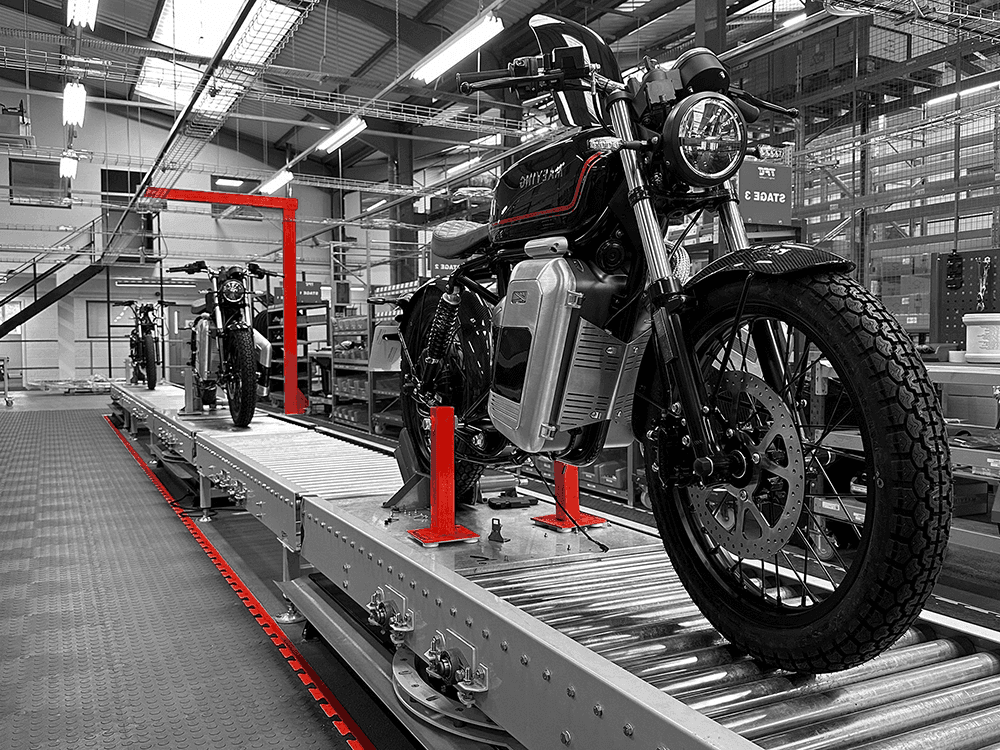

Slat Conveyors - slat conveyors use a series of slats or plates to move products carefully and are suitable for heavy, rigid products, the transfer of sterile product trays, or those requiring precise positioning. Slat conveyors are highly durable and offer precise control over product orientation.

Vacuum Conveyors – vacuum conveyors are critical for transferring powders and granules without contamination, using air suction to move material through enclosed tubing. They offer dust-free operation and a reduced risk of contamination, and are often used within cleanroom or controlled environments for powder handling in tablet manufacturing or bulk ingredient transport.

Cleanroom Conveyors – these are designed specifically for environments where maintaining extremely low levels of particulates is vital. Cleanroom conveyors are built with minimal crevices and surfaces that resist microbial growth and are typically used for aseptic product handling, sterile filling lines, and packaging in controlled environments. They offer ISO-Class 5-8 compliance, are easy to sanitise, and offer minimal particle generation.