Why Customisation is Key

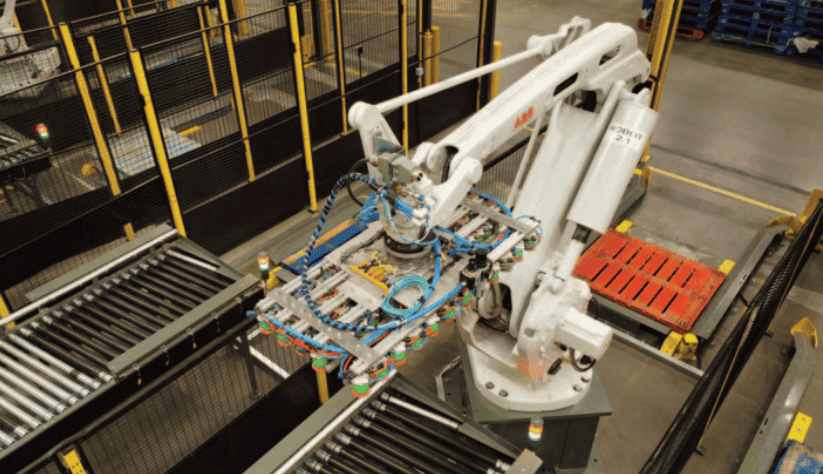

Standard robotic systems can offer a solid foundation for automating tasks; however, they often fall short when it comes to addressing the specific challenges and intricacies of individual and often complex operations. No two production lines or warehouses are the same, highlighting the need for customisation to deliver that all-important strategic advantage. Custom robotic systems are designed with your unique processes, constraints, and goals in mind.

Rather than imposing generic solutions on your operations and expecting them to adapt with little impact on performance, customised automation fits seamlessly into existing processes, enhancing efficiency, precision, and flexibility. From tailored robotic end-effectors to integration with legacy control systems, customisation provides a route to leverage the full potential of industrial robotics by aligning technology directly with business operations and objectives. In an increasingly competitive and cost-sensitive market, customisation can make the difference between success and failure. Here we outline some of the key benefits of customised robotic solutions.

Alignment with Operational Objectives

Every warehouse layout or production line has unique workflows and challenges. Custom robotic systems can be designed to align with existing infrastructure and integrate with other technologies such as conveyor systems, control systems, or Warehouse Management Systems, ensuring seamless operation and minimal downtime.

- Flexibility and Scalability

Custom systems are built with future scalability in mind. Whether the design is modular to facilitate future gripper changes or enables software updates for evolving SKUs, these systems scale and adapt as your automation needs grow.

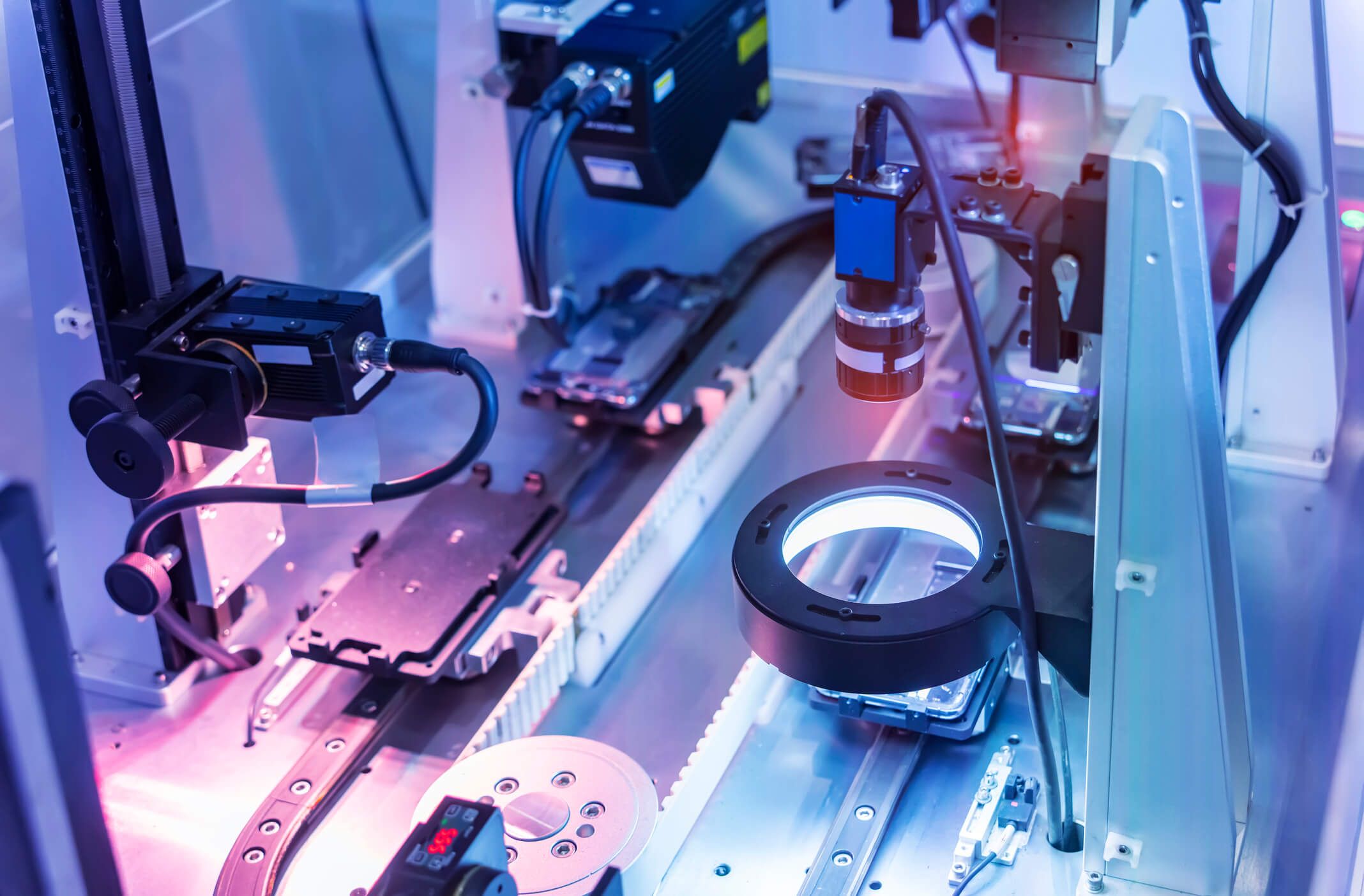

- Maximising Efficiency and ROI

Tailored robotic systems ensure that productivity and accuracy are optimised, enhancing throughput and eliminating the risk of bottlenecks or product defects. By improving performance, custom solutions deliver on both efficiency and ROI levels and reduce reliance on error-prone manual processes.

- Compliance and Safety

Custom design of a robotics solution enhances workplace safety by automating potentially dangerous tasks, eliminating the need for heavy or repetitive manual activities that could cause fatigue or injury to workers. Using a custom design also ensures the system complies with industry-specific regulations, particularly important for the pharma, automotive, and food and beverage sectors.

The Value of Process Understanding in Custom Design

Customisation begins with understanding every facet of the business, its processes, products, challenges, and objectives. From understanding the most critical production pain points, such as processes that cause delays or waste, to managing the interaction between human workers and automation, finding the answers requires in-depth engagement supported by bespoke automation and advanced robotic systems.

Through on-site assessments, data analysis, and collaborative planning, a bespoke system can be designed to overcome your real-world challenges, boost workflows, and support scalable, long-term growth through predictive maintenance and system design aligned with your operation.