The Road Ahead for UK Industry

With the UK government remaining focused on ‘levelling up’ and advancing Industry 4.0 initiatives for wider usage, robotic integrations are expected to play a crucial role, with grants from Innovate UK and schemes such as Made Smarter already supporting businesses and fuelling the adoption of robotic technologies, vital for driving automation and efficiency forward.

Additionally, to position the UK as a global leader in robotics and smart machines, the government has developed a comprehensive roadmap: Smart Machines Strategy 2035. Published in February 2025, this 10-year plan highlights the potential of intelligent, semi-autonomous systems and how they can transform business operations.

The plan covers the economic impact, including statistics around full adoption of smart machines having the potential to boost the UK’s Gross Value Added from £6.4 billion to £150 billion by 2035, through productivity, cost reductions, and the emergence of new industries and job opportunities.

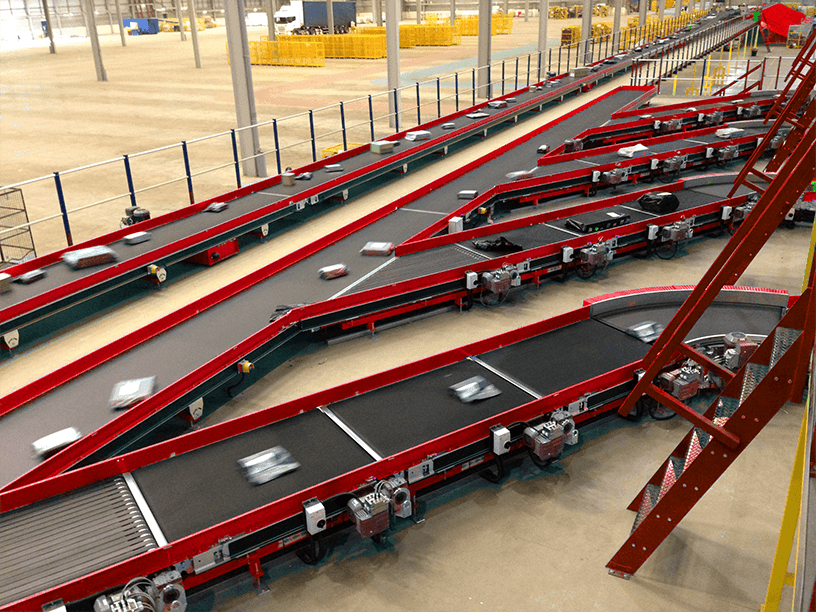

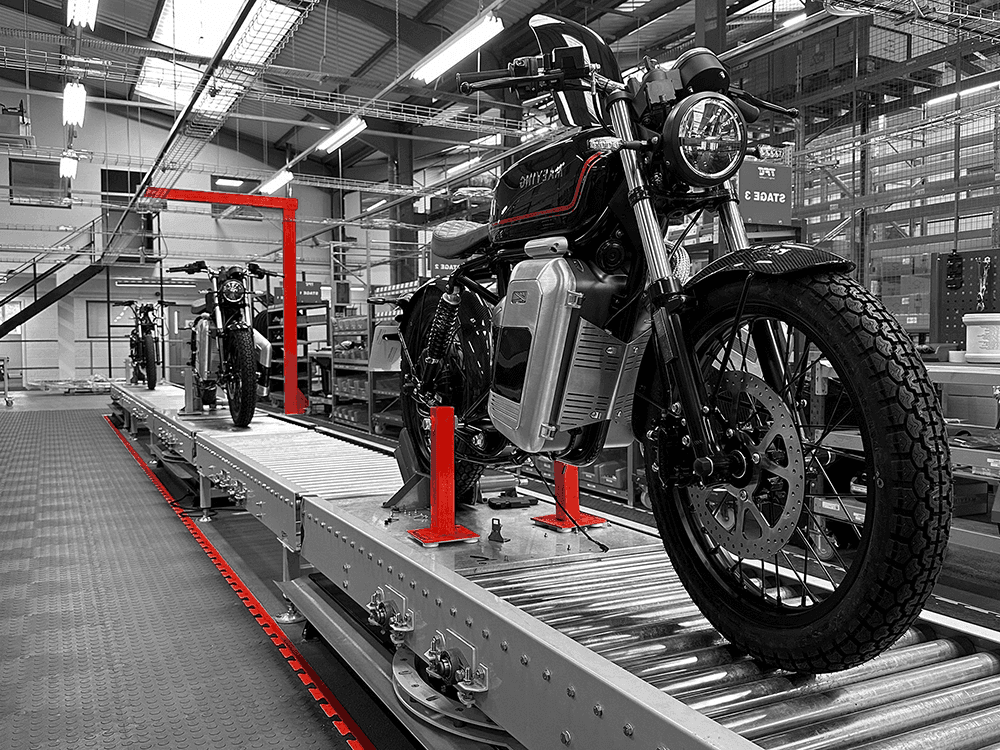

Outlining the roadmap’s strategic goals, the report headlines key goals focused on the integration process of AI and robotics to promote the development and deployment of intelligent systems that can operate seamlessly alongside humans. This fully supports the growing uptake in cobot integration, which has the capability of streamlining logistics and manufacturing operations further, while enhancing workplace safety.

Acknowledging the UK’s strength in research and innovation to drive advancements in robotic automation and smart automation systems, the strategy showcases the importance of organised and collaborative action needed to integrate robotics and smart machines to ensure that these rapidly evolving advanced technologies deliver long-term success and tangible benefits for UK industry.