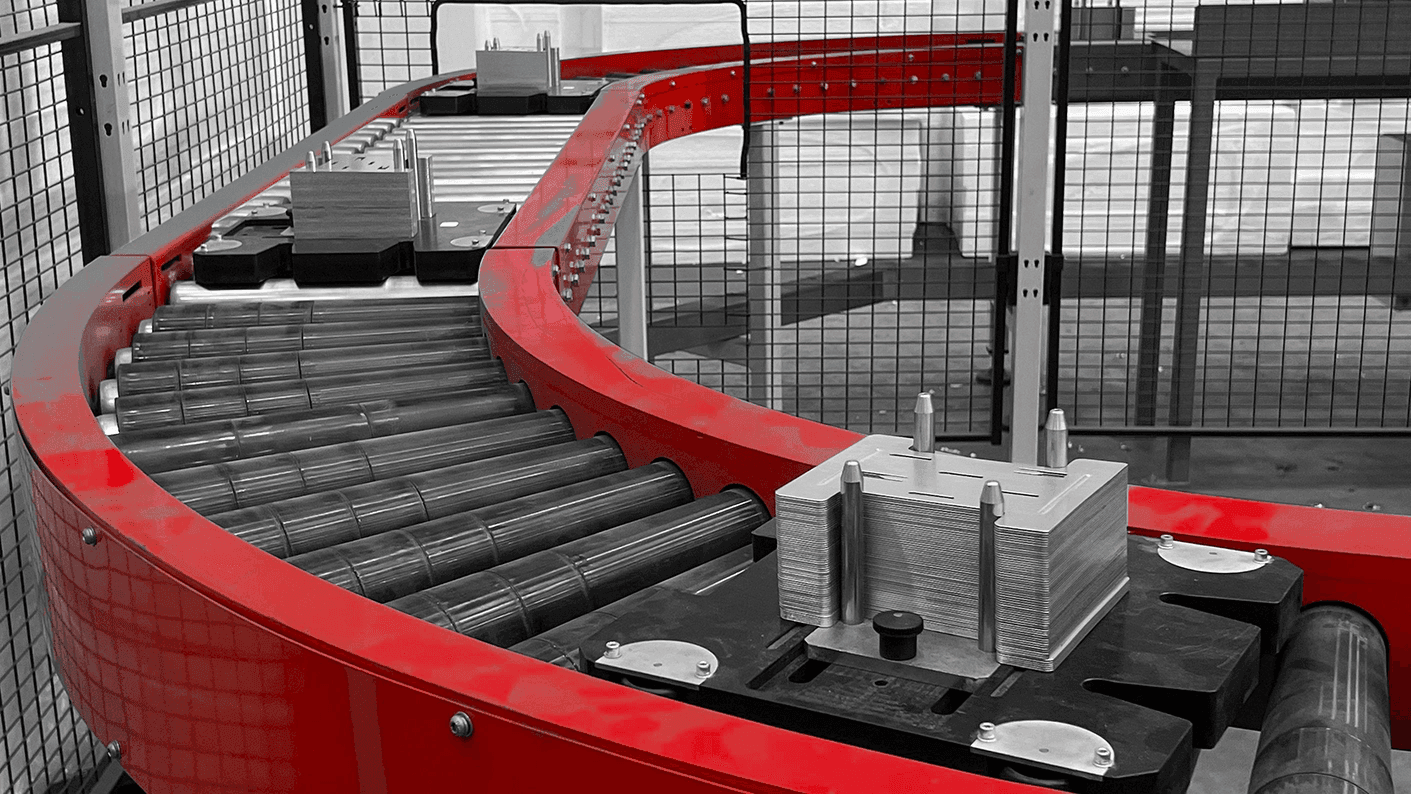

Roller Conveyors: Versatile and Reliable

Roller conveyors remain one of the most widely used systems in warehouse operations. These warehouse conveyors consist of conveyor rollers mounted in frames, transporting goods either through gravity or powered mechanisms. Gravity conveyors work well on slight inclines, requiring no electricity and offering low operational costs. They are ideal for moving boxes, totes, and pallets over short to medium distances.

Powered Conveyors, typically lineshaft driven or chain-driven, handle heavier loads and provide greater control over product handling. They excel in environments requiring precise positioning, such as sorting sections or accumulation zones where products queue before the next process. The modular design of roller conveyors makes them adaptable to various warehouse systems and easy to expand as operations grow.

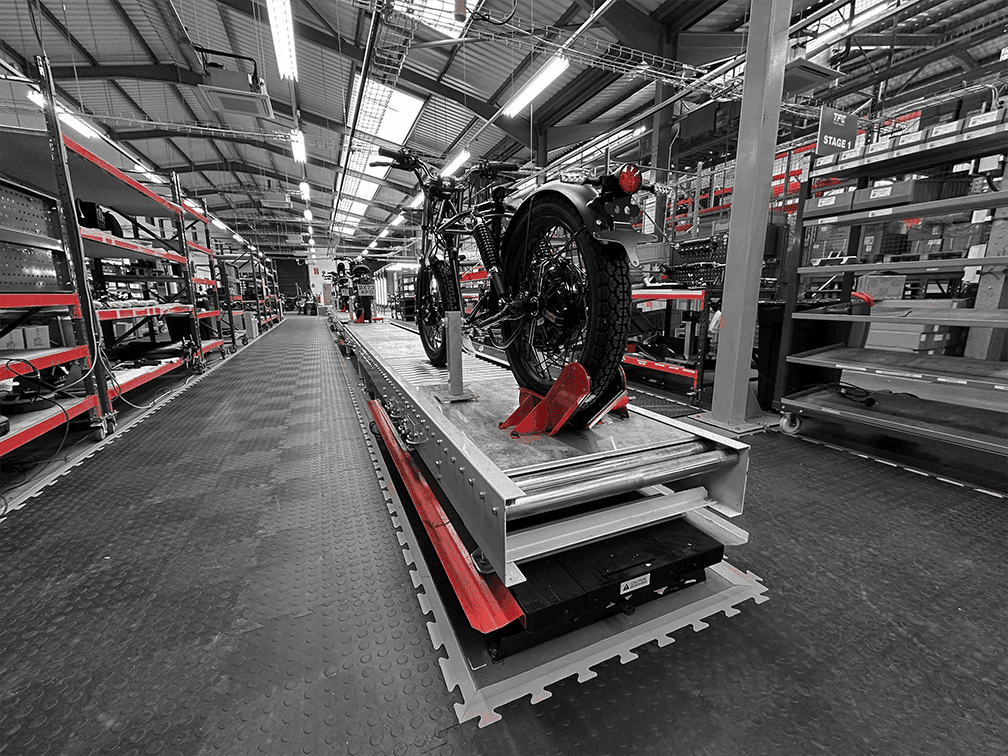

Belt Conveyors: Handling Diverse Products

Belt Conveyor Systems utilise continuous belts to transport materials and are particularly effective for irregularly shaped items, loose products, or goods that might fall between rollers. The smooth, continuous surface accommodates fragile items, small components, and products with flat bottoms that rollers might struggle to move efficiently.

These systems work exceptionally well in picking operations, where items of varying sizes travel along the belt for consolidation. Transportation conveyors also handle inclines and declines more effectively than many alternatives, making them suitable for automated warehouses with multiple levels. Their versatility extends to both light-duty applications and heavy industrial use, depending on belt material and construction.

Chain Conveyors: Heavy-Duty Performance

When warehouses handle pallets, heavy containers, or industrial materials, chain conveyor systems deliver the robust performance required. These systems use chains running in tracks to pull loads along the conveyor path. They manage substantial weights that would overwhelm belt or roller systems and withstand harsh environments, including extreme temperatures and exposure to oils or chemicals.

Chain conveyors prove invaluable in automotive parts warehouses, manufacturing facilities with raw materials, and distribution centres handling building materials. Their durability translates to lower maintenance costs over time, despite higher initial investment compared to lighter-duty alternatives. For larger systems, integrating pallet conveyors enhances material flow and overall operational flow.

Sortation Conveyors: Streamlining Distribution

Modern warehouses increasingly rely on sortation conveyor systems to direct products to specific destinations automatically. These sophisticated systems use technologies such as pop-up wheels, sliding shoes, or pusher mechanisms to divert items onto different lanes based on destination, order, or product type.

Sortation conveyors dramatically reduce the time and labour required for order fulfilment, particularly in high-volume e-commerce and supply chain operations. They integrate with warehouse management systems and warehouse automation solutions to ensure accurate routing and can process hundreds or thousands of items per hour. While representing a significant capital investment, sortation systems often deliver rapid return on investment through labour savings and increased throughput.

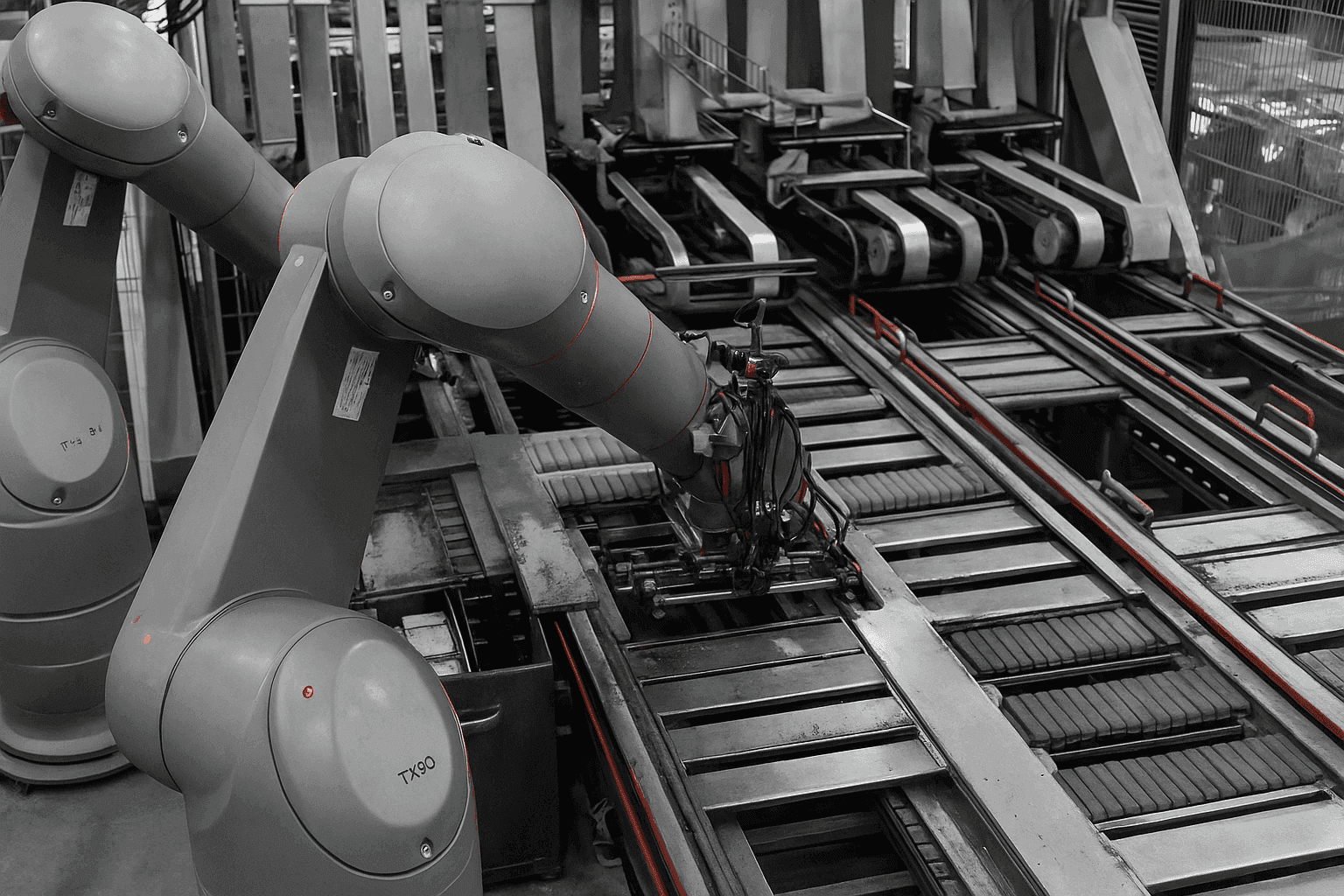

Overhead and Vertical Conveyors: Maximising Space

Warehouses facing space constraints benefit from overhead and vertical belt conveyors, which move goods efficiently throughout facilities while maximising floor space. These systems work particularly well for garments, automotive parts, and products requiring specific environmental conditions during transport.

The vertical approach reduces contamination risks by keeping products away from floor-level debris and foot traffic. Overhead systems can integrate with warehouse robots or automation technology for smarter loading and unloading, improving both speed and safety. However, these systems require strong building structures and careful planning for maintenance and accessibility.