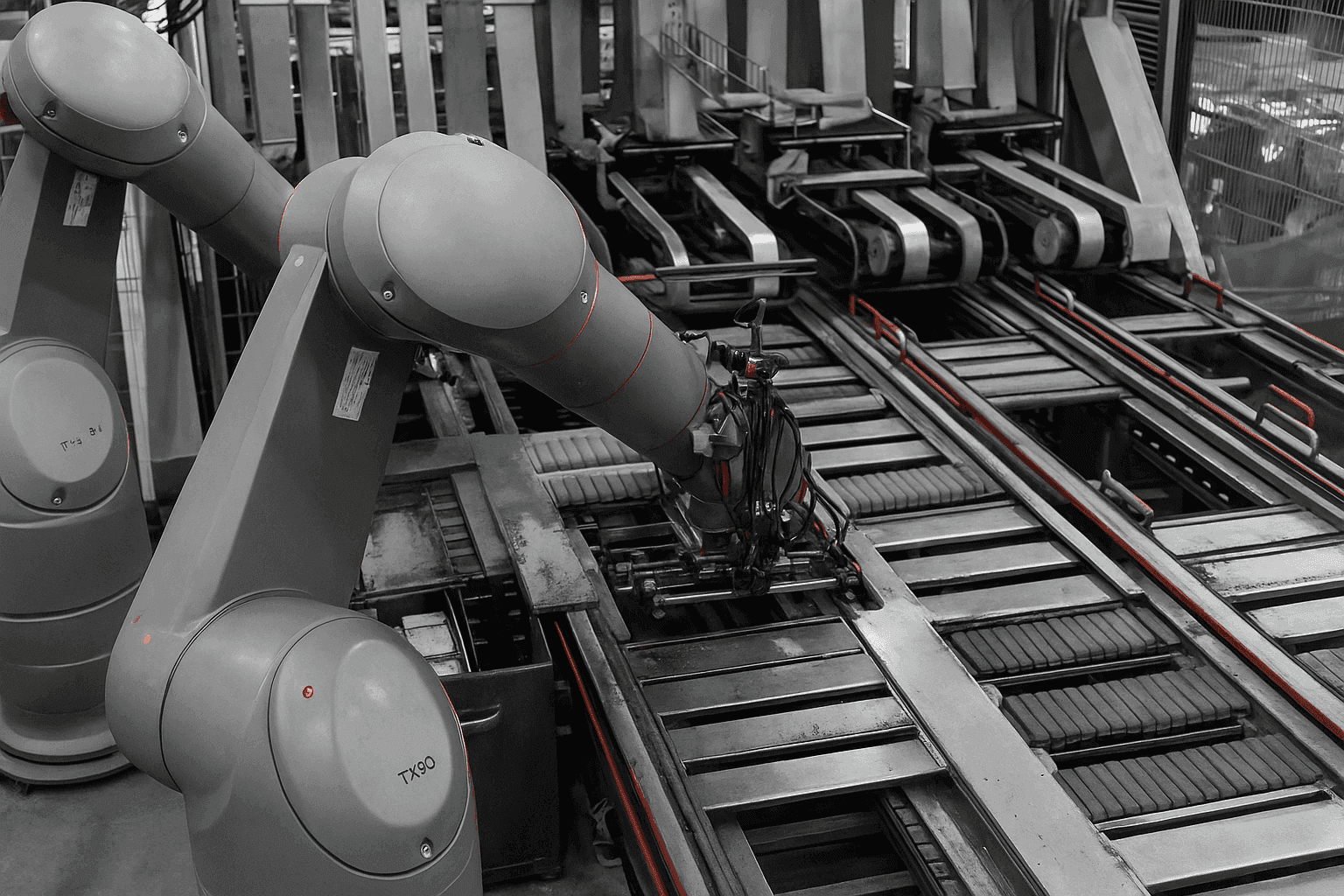

Integration with Advanced Technologies

Modern industry increasingly relies on automation, data analytics, and smart manufacturing technologies. Custom conveyor belt systems can be designed to integrate seamlessly with these advanced capabilities from the outset.

Bespoke designs can incorporate sensors, vision systems, and automated sortation mechanisms that support Belt Conveyor Systems and chain conveyors for more complex setups. These can be paired with connectivity features that enable real-time monitoring and data collection. This integration allows businesses to leverage Industry 4.0 technologies effectively, improving decision-making and operational visibility.

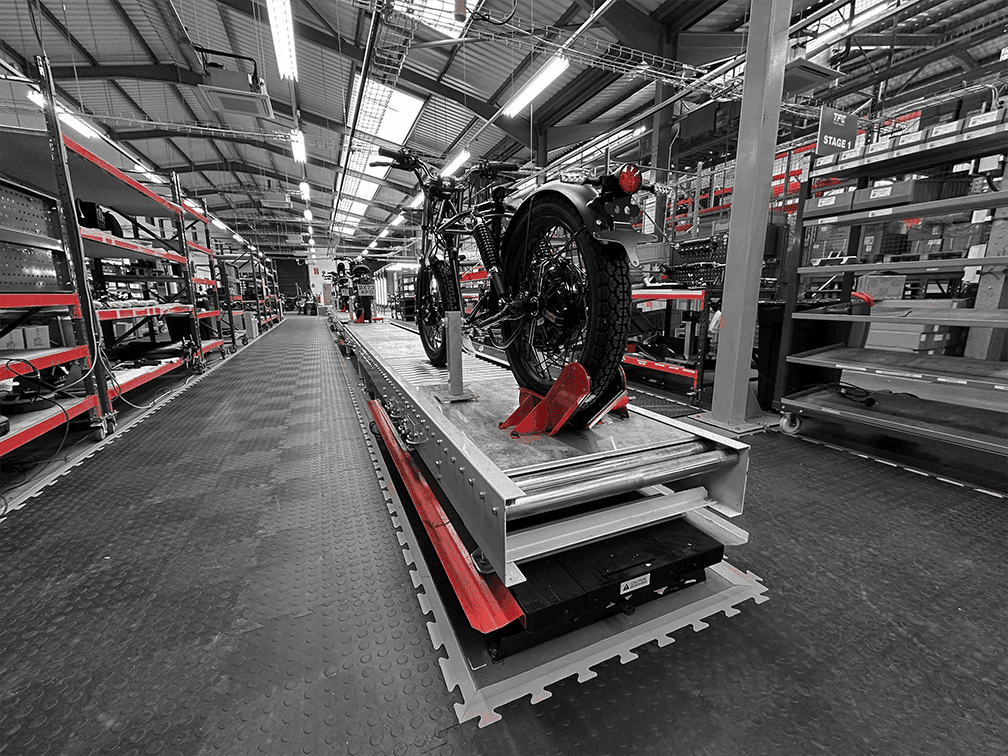

Reduced Maintenance Requirements

Generic conveyor systems may include components that experience excessive wear due to applications they weren’t specifically designed to handle. Custom Roller Conveyors and powered roller systems, engineered for precise operational parameters, typically experience more balanced component loading and reduced strain on individual elements.

This optimised engineering can extend component lifespan, reduce maintenance frequency, and lower overall lifecycle costs. Additionally, custom designs can incorporate accessibility features that simplify routine maintenance tasks, reducing downtime and labour requirements.