Conveyor Systems in Warehousing and Manufacturing

Conveyor belts and belt systems, across their many forms, continue to be integral to efficient operations. In warehousing and logistics, they ensure the fast and accurate movement of parcels, cartons, and pallets, often forming part of wider automated systems and automation technologies.

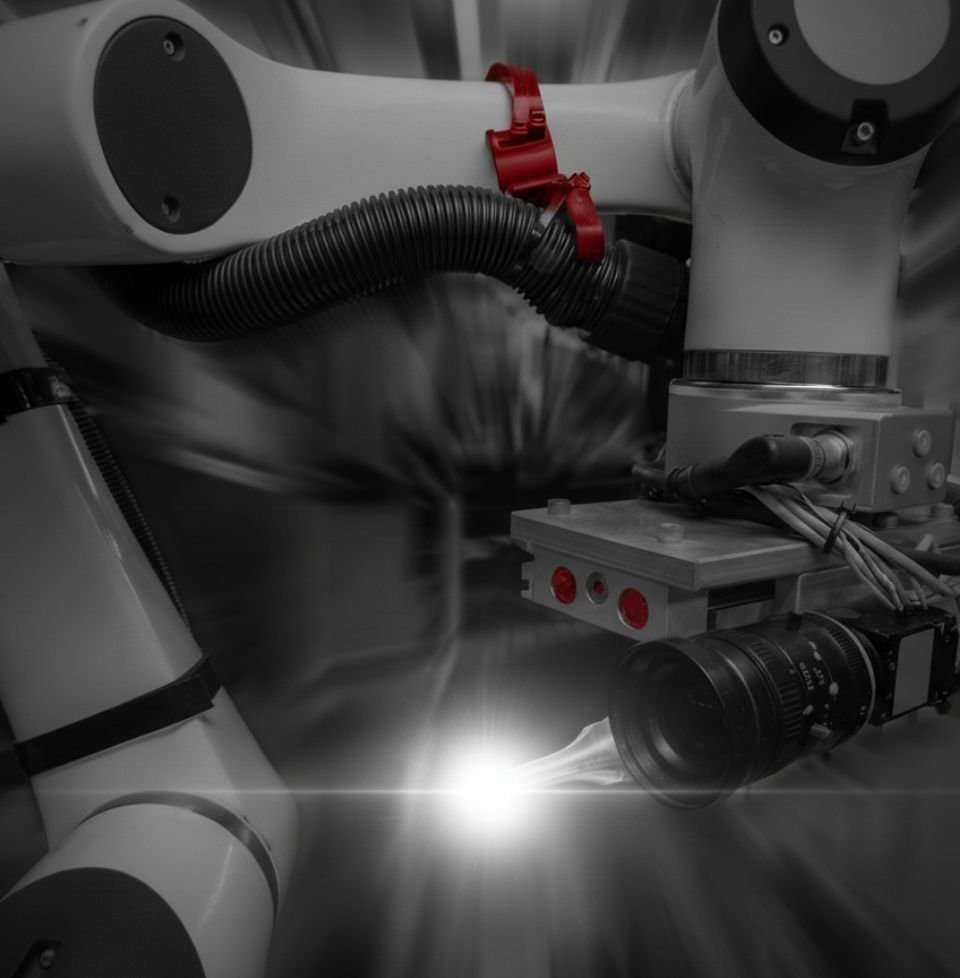

In the manufacturing industry, they provide production line efficiency by linking workstations with just-in-time supply of raw material, vital to support a variety of manufacturing processes such as welding and assembly.

Types of customisable conveyor systems in use across warehousing and manufacturing include:

- Belt conveyor systems – widely used for moving cartons, parcels, and food products, available in a range of belt material options to suit application needs.

- Roller conveyors – particularly effective for heavier loads such as pallets and totes.

- Overhead conveyors – often deployed in the automotive and garment sectors to free up valuable floor space.

- Modular conveyors – designed for flexible layouts that can adapt as warehouse or production needs change.

- Hybrid conveyors – solutions combining traditional conveyor efficiency with robotic systems or Automated Guided Vehicles to optimise space and labour.

Products handled range from:

- Lightweight goods such as e-commerce packages and clothing.

- Heavy-duty loads, including pallets and machinery parts.

- Sensitive items like pharmaceuticals, electronics, and fresh food requiring quality control systems and specialist handling.

While items handled by conveyor systems vary significantly in size, shape, and weight, conveyor solutions remain a robust and reliable way to transport goods to ensure accurate, efficient, and high-volume throughput in a safe working environment.