The Current State of Robotics in Supply Chain Operations

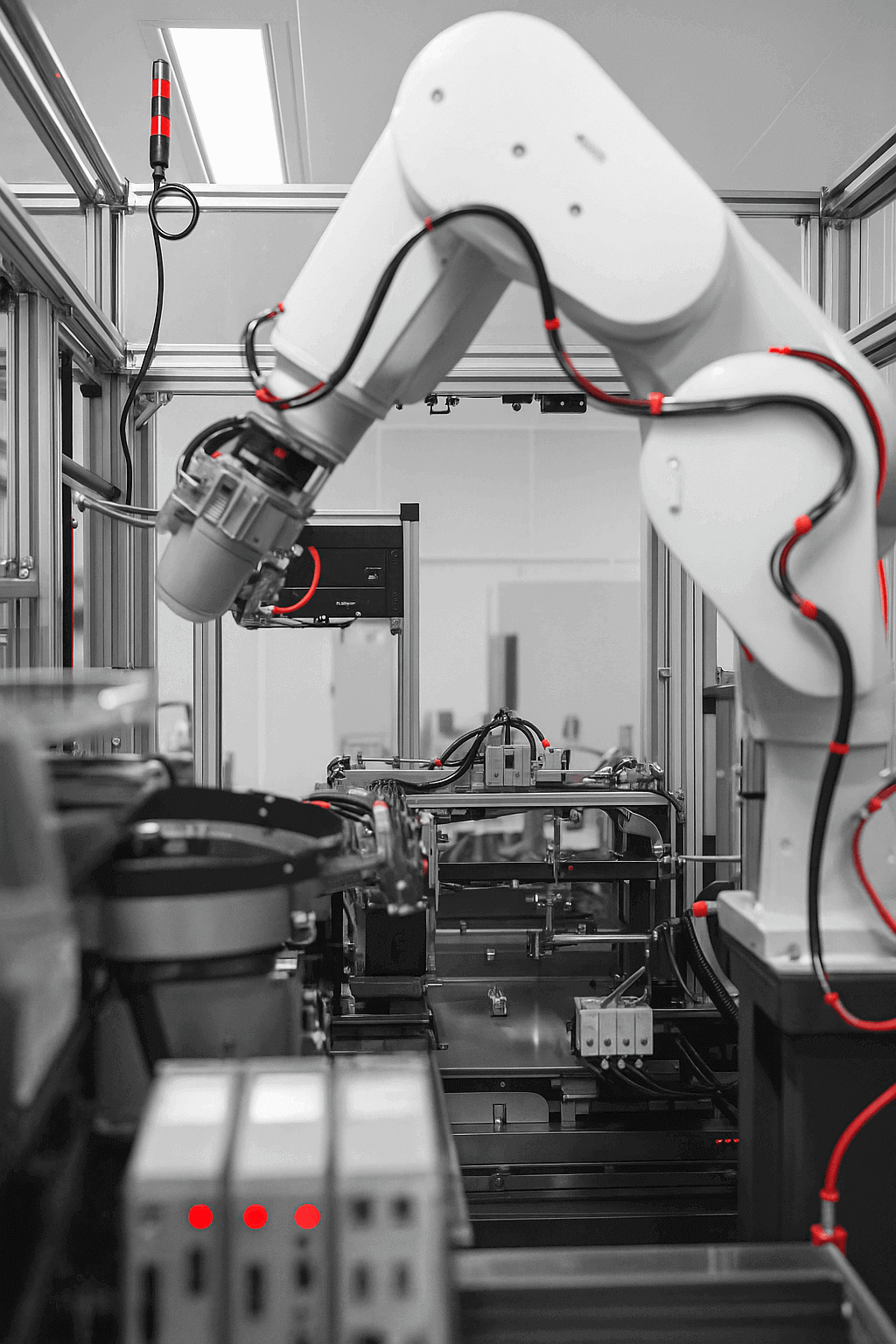

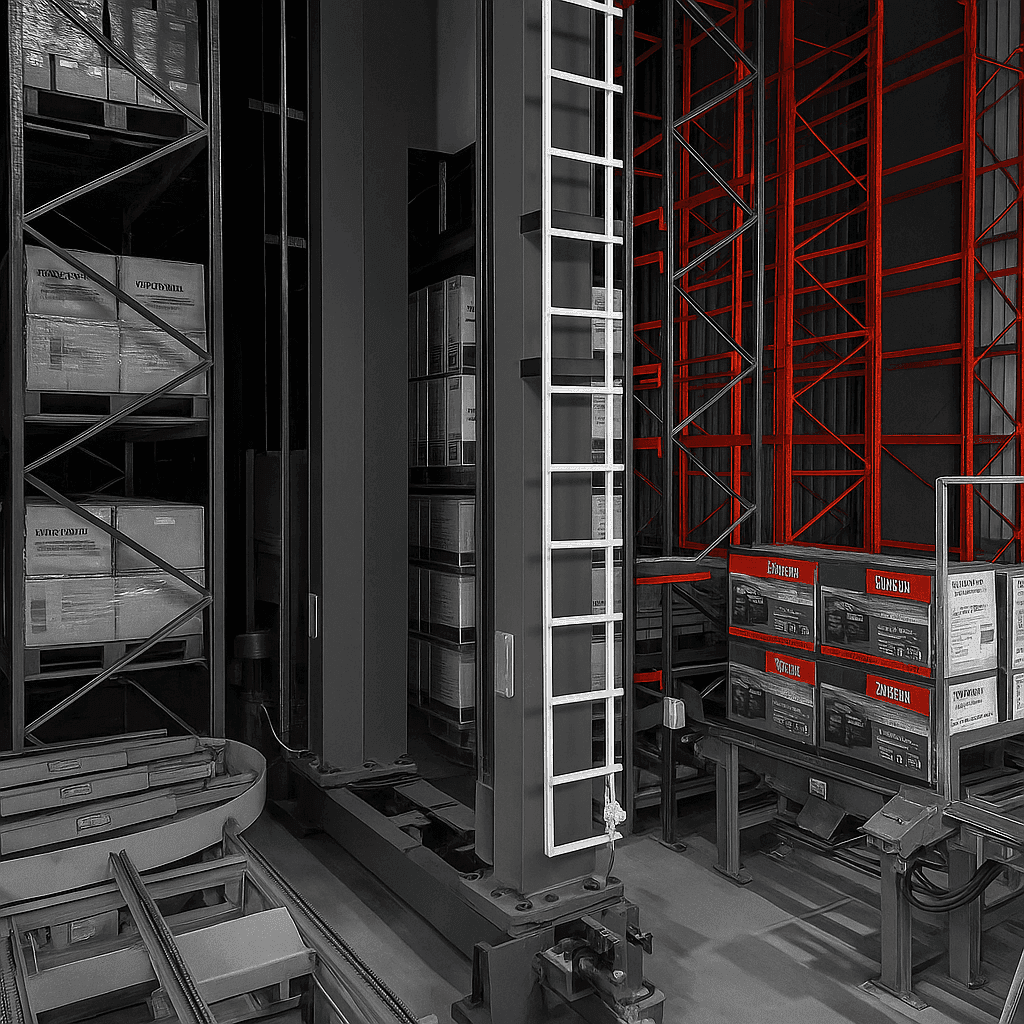

Robotics technology has evolved significantly over the past decade. Today’s autonomous systems combine artificial intelligence, machine learning, and sophisticated sensors to perform complex tasks with minimal human intervention. These are not the rigid, single-purpose machines of previous generations. Modern robotic systems adapt to changing conditions, learn from their environment, and integrate seamlessly with existing warehouse management systems and automated storage and retrieval systems.

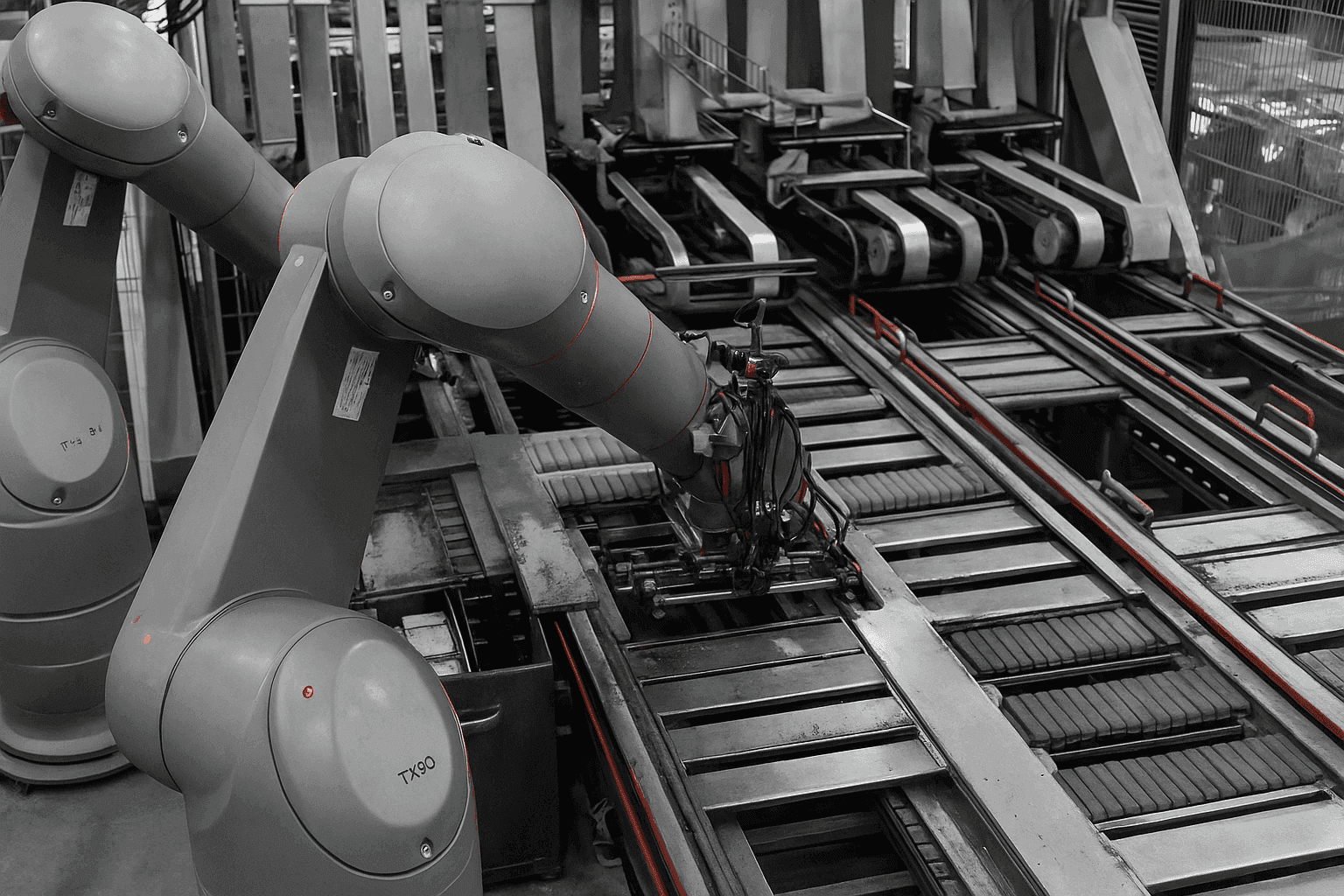

Warehouses represent the most visible application of this technology. Autonomous mobile robots (AMRs) navigate vast facilities, transporting goods between stations without fixed tracks or extensive infrastructure modifications. Robotic arms pick, pack, and palletise items with precision that far exceeds human workers, particularly for repetitive tasks. Collaborative robots, or cobots, work alongside employees, handling the physically demanding aspects whilst workers focus on decision-making, system supervision, and quality control.

The technology extends beyond the warehouse. Automated guided vehicles (AGVs) manage inter-facility transport, while drone technology is beginning to transform inventory management in large-scale operations. Some facilities now conduct stock checks in hours rather than days, using drones equipped with RFID scanners and computer vision to improve inventory visibility and real-time inventory tracking.