Manufacturing Applications for Vision-Guided Robotics Systems

Vision-guided robotics offers extreme versatility and can be adapted to a wide range of manufacturing applications through a combination of robot type, vision sensor, and imaging system installed. Here are some of the most common applications for vision-guided robotics systems in manufacturing today:

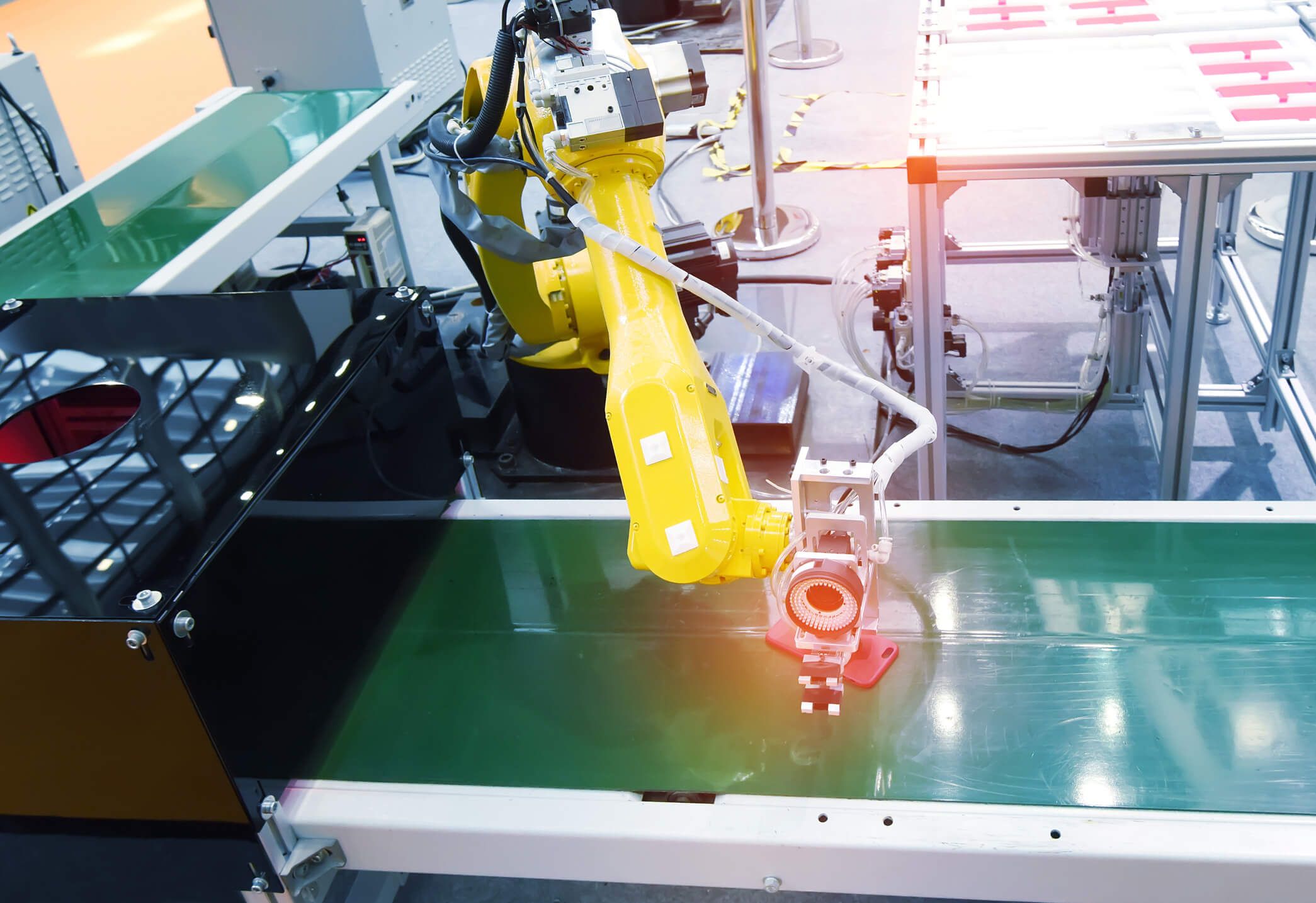

- Pick and Place – locate, identify, and pick up oriented or randomly placed items from bins, conveyors, or conveyor belts, and place them accurately in designated zones.

- Assembly – guide robots to precisely position and assemble components, even in complex or dynamic assembly tasks, improving production efficiency.

- Inspection – capture images of products or components, and image processing software can analyse them for defects, ensuring quality control throughout the production line.

- Material Handling – move parts between different workstations, load and unload machines, and perform other handling tasks with greater efficiency and safety through robot guidance and closed control loops.

- Palletising and Depalletising – automate the stacking and unstacking of products on pallets, improving speed, accuracy, and reducing the reliance on manual labour.

- Manufacturing Logistics – sort, track, and move manufactured products within warehouses for enhanced inventory visibility and traceability supported by machine vision systems.

- Guidance for Collaborative Robots – enhance the capabilities of collaborative robots such as Universal Robots cobots, enabling them to work safely alongside humans in picking and order fulfilment tasks.