Robotics in Fulfilment Operations

In dynamic e-commerce and fulfilment operations, speed and precision are paramount. Robotics plays a crucial role by automating tasks in warehouses and distribution centres, and comes in a wide range of options. Here are some of the main types of robotics used:

Autonomous Mobile Robots (AMRs) – AMRs navigate independently within warehouses to transport items in totes, on pallets, or entire shelving units. They use LIDAR sensors, obstacle avoidance, and dynamic path planning to ensure they are safe to operate fully autonomously within the warehouse environment. AMRs provide a flexible, easy-to-scale solution with no need for fixed infrastructure. AMRs are a growing segment of the robotic fleet deployed across warehouses and fulfilment hubs.

When used in Goods-to-Person fulfilment operations, AMRs are typically in an enclosed area where goods are held in a high-density storage structure. The AMRs retrieve items stored in totes or trays and transport the full tote to integrated workstations, for manual workers to remove, scan, and process the required items, ready for packing and dispatch.

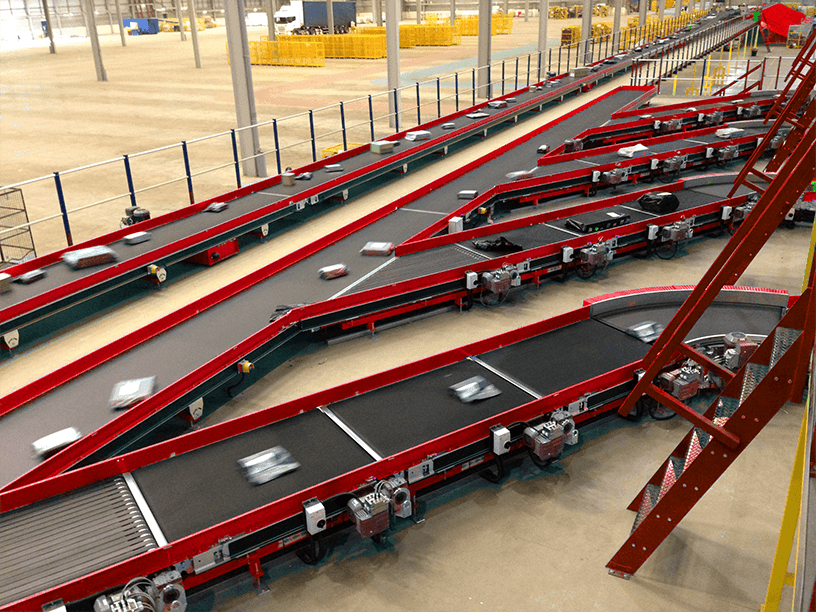

Automated Guided Vehicles (AGVs) – AGVs also work autonomously but follow fixed routes to move goods around a warehouse or depot environment. They use magnetic tape or tracks for navigation and offer a high level of reliability in structured environments. AGVs can be scaled up or down easily in response to demand and are a cost-effective solution for carrying out repetitive material handling tasks.

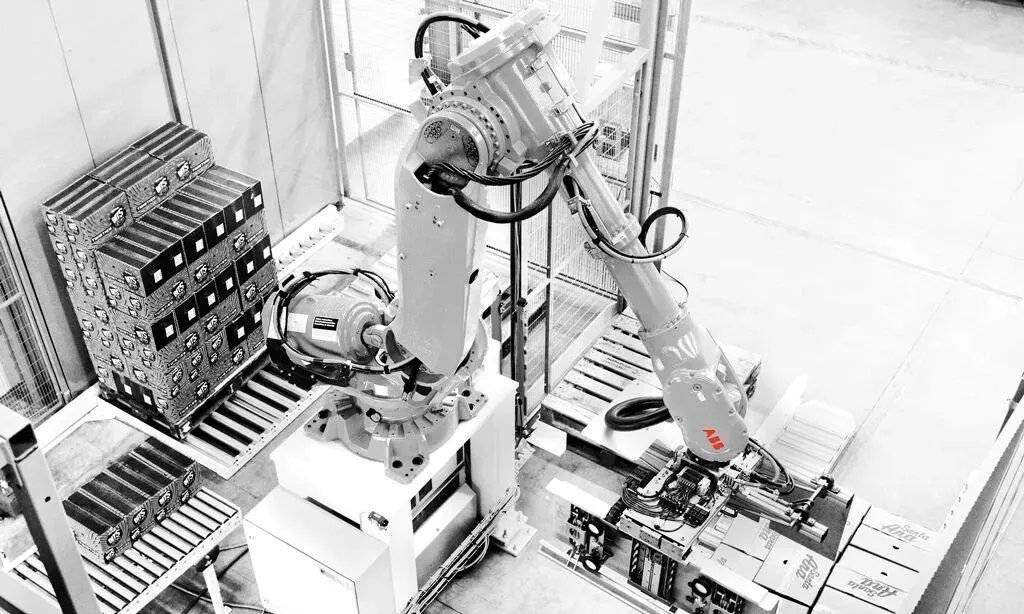

Robotic Arms (Pick-and-Place Robots) – Highly versatile, robotic arms or pick-and-place robots automate the process of picking, sorting, and packaging goods. They use integrated vision systems and end-of-arm grippers, which can be tailored to specific product types. Robotic arms reduce the risk of human error and speed up order assembly and processing, enhancing throughput and efficiency. Robot modification and customised robot software models are often used to tailor robotic arms to specific fulfilment environments.

Collaborative Robots (Cobots) - Cobots are increasingly seen in the warehouse environment, working alongside humans to support a number of key tasks such as order picking and inventory replenishment. Cobots feature advanced interaction protocols to ensure safe working proximity with humans, and help to both augment human task performance and improve ergonomics with reduced manual handling requirements.

Drones (for inventory management) - Becoming more widespread, drones are integrated into e-commerce and fulfilment operations to fly within warehouses, scanning inventory and inspecting stock levels. They feature barcode scanning and thermal imaging technology and offer a cost-effective solution for fast stocktaking, reducing the need for labour-intensive inventory audits.

Integrating AI with Robotics: Enhancing Fulfilment Operations

Integrating AI offers a significant boost to operations by dramatically enhancing the capabilities of fulfilment robots. This enables them to make real-time decisions, such as an AI algorithm can direct AMRs to reroute in response to congestion or delays. AI can also analyse performance data to predict when a robot may fail, minimising the potential downtime and loss of productivity caused by a robot suddenly being out of use. For enhanced resource allocation, AI prioritises tasks based on urgency, load, and availability, offering a balance of productivity across robots for optimum efficiency.