What is Warehouse Robotics?

Warehouse robotics refers to the use of automated machines and systems specifically designed for performing tasks within warehouse environments. Unlike traditional methods that rely heavily on human operators, robotic systems provide continuous, accurate, and efficient handling of goods. Warehouse robotics aims to automate repetitive and labor-intensive tasks, freeing up the human workforce for more complex roles. This warehouse automation translates into better warehouse efficiency, as robotic systems can work without the breaks or shift changes required by human labour, ultimately increasing warehouse productivity.

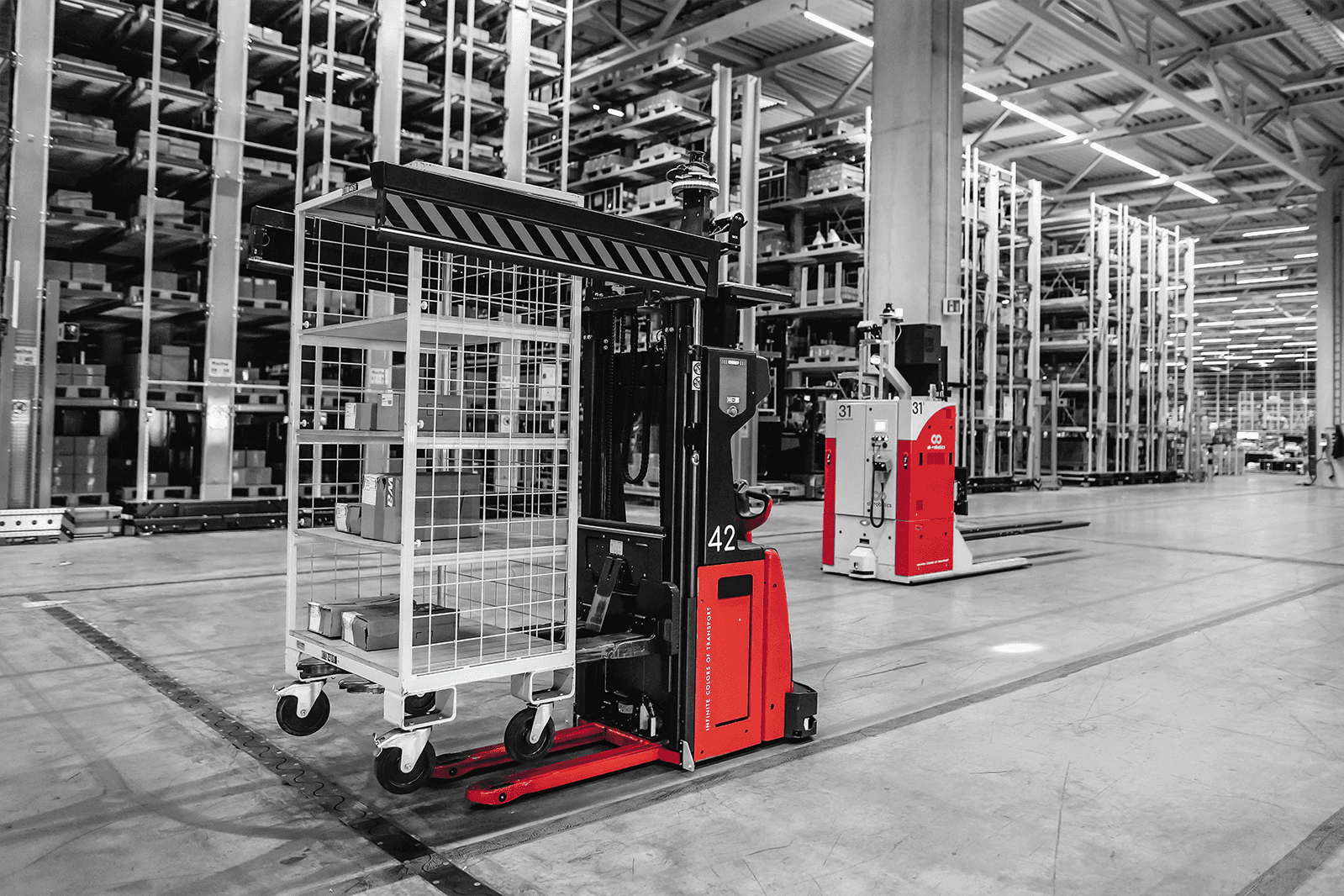

Robotic warehouse systems streamline various logistics operations, from picking and packing to sorting, inventory management, and product transport. These systems combine physical robots with specialised software to manage warehouse operations, utilising artificial intelligence to adapt to dynamic environments. Using innovative technologies like advanced sensors, cameras, and AI-powered software, these systems can identify objects, make real-time decisions, and even adapt to changing environments. For instance, autonomous robots such as AMRs operate independently, navigating complex warehouse spaces, while Collaborative robots (cobots) work alongside human operators to enhance productivity in tasks like packing or order picking.

Companies handling large inventories, heavy goods, or experiencing seasonal surges find these robots particularly advantageous. With their ability to scale operations up or down more flexibly than human labour, warehouse robotics has become indispensable in meeting fluctuating consumer demands and achieving an efficient supply chain