Challenges of Manual Handling Vs Upgrade to Robotic Automation

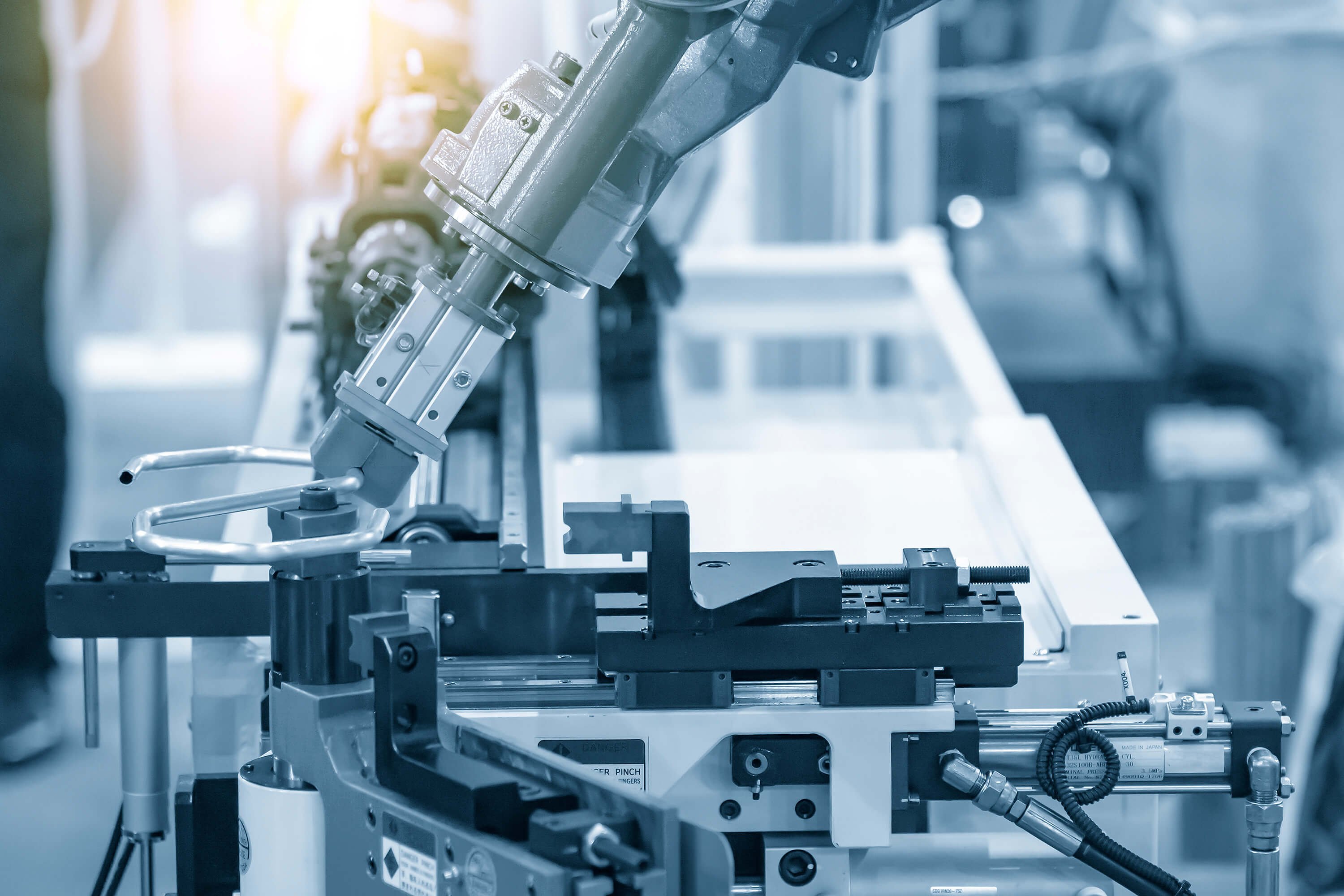

Manual handling often brings a high risk of repetitive strain and injury. By introducing robotic upgrades such as cobots, palletisers, and AMRs, these heavy or repetitive lifting and handling tasks can be removed, significantly reducing strain on workers.

Inconsistent task times and variable quality are another challenge with manual processes. Robotics solves this with programmed, repeatable motion, while integrated vision systems deliver precise quality control that is consistent across every cycle.

Labour gaps and seasonal peaks can disrupt productivity, especially in industries that rely heavily on manual staff. Scalable robotic fleets, supported by automated guided vehicles, ensure 24/7 operation and the flexibility to handle increased demand during peak periods.

Space constraints often limit manufacturing efficiency. With AS/RS solutions and AMR picking structures, businesses can achieve high-density storage that maximises floor space and streamlines operations.

Finally, traceability and compliance issues are a recurring concern in manual handling. Automated systems capture data in real time, providing accurate inventory visibility and tracking that supports both compliance and operational efficiency.