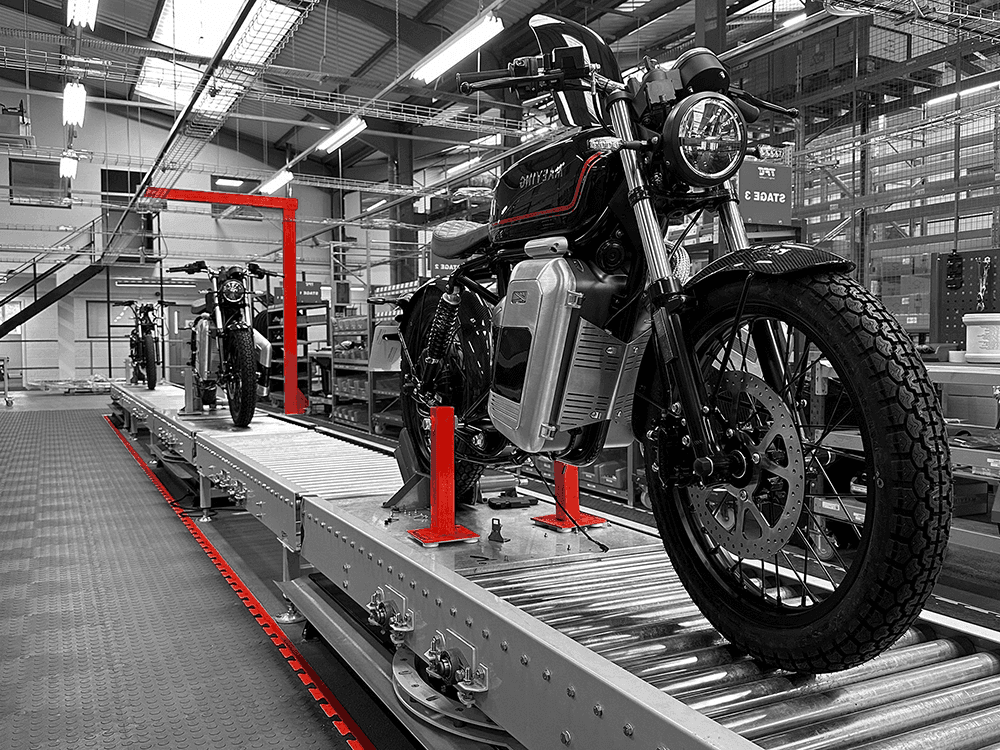

Why Invest in a Smart Conveyor System?

As technologies continue to advance, creating increasingly intelligent conveyors, investment in a smart conveyor system offers a combination of efficiency and adaptability to future-proof operations. Upgrading to a smart conveyor system is more than taking a technological leap forward; it’s a vital strategic move for long-term competitiveness.

Here is just a selection of the many reasons why it’s worth considering smart conveyor integration:

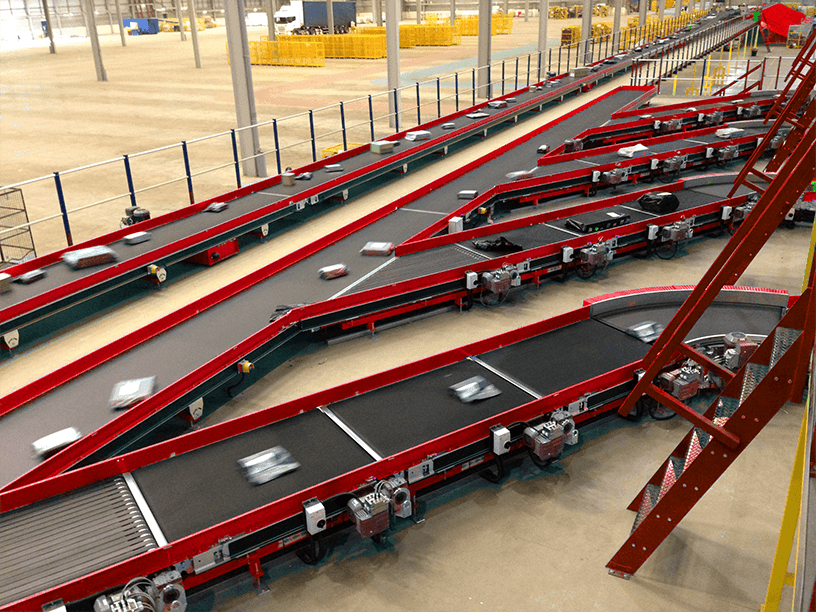

Increased Throughput

Smart conveyors can process more items in less time with greater accuracy, enabling faster order processing and delivery.

Labour Cost Reduction

By automating repetitive tasks, businesses can redeploy human workers to higher-value roles, reduce dependency on manual labour in a challenging employment market, and improve workplace safety.

Real-Time Operational Visibility

Integrated sensors and cloud platforms provide managers with real-time monitoring of system performance, error alerts, and predictive maintenance insights.

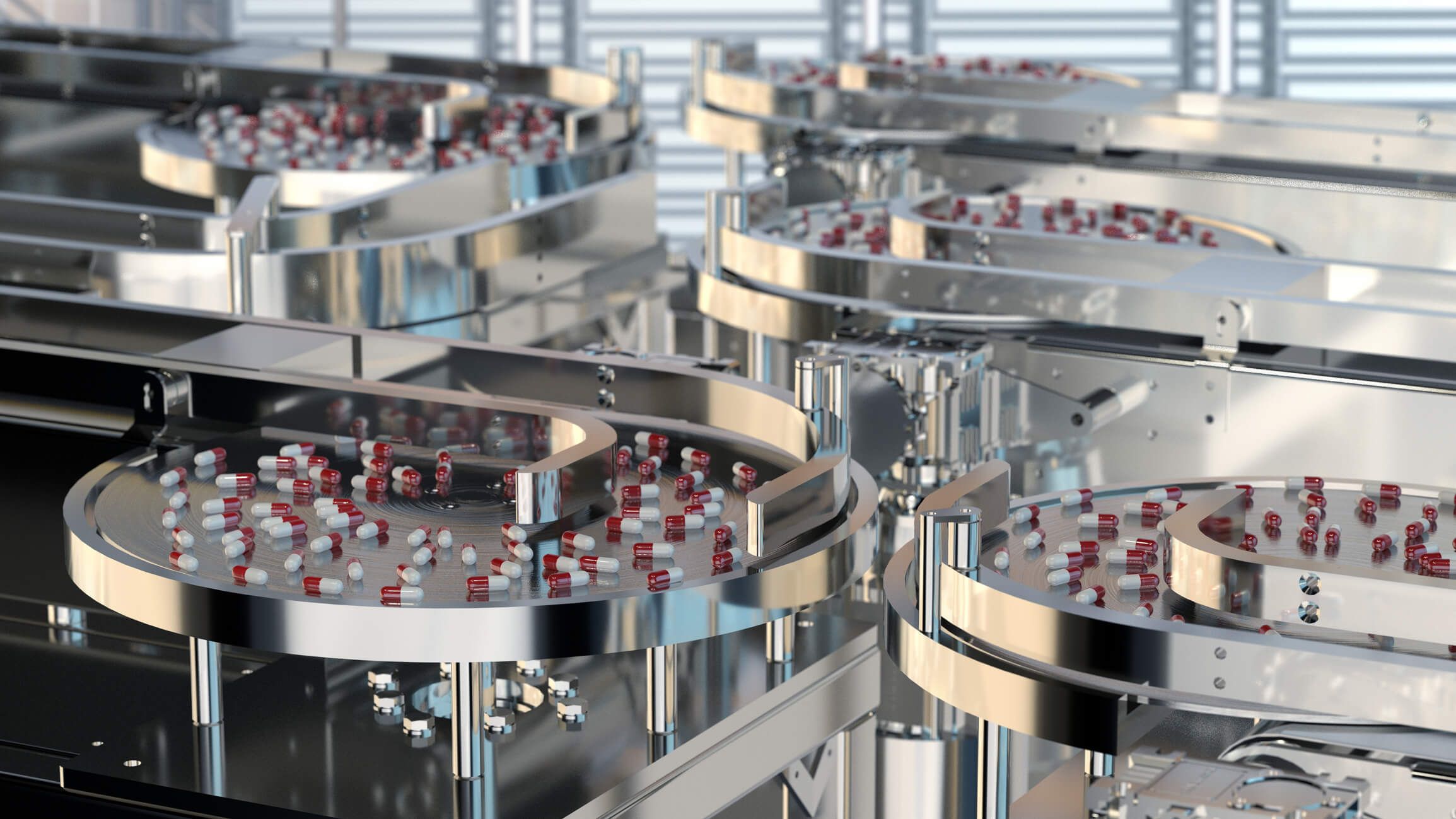

Improved Accuracy and Quality Control

Smart systems can verify weights, detect mislabels, and reject damaged goods before they leave the facility, enhancing quality management across the supply chain.

Scalability and Flexibility

Modular components allow smart conveyors to be reconfigured and scaled to meet seasonal spikes, product changes, or growing demand. This can be vital for fast-moving industries such as e-commerce, which are often impacted by the supply chain as well as consumer and seasonal demand.

Energy Efficiency

On-demand power usage, automatic sleep modes, and smart start/stop functions contribute to lower energy bills and improved sustainability.

Using the very best technology solutions on the market, smart conveyor systems offer significant operational advantages, from higher throughput to real-time monitoring and actionable data insights. By enhancing accuracy, improving quality management, and providing scalability to adapt to changing business needs, the benefits wholeheartedly support the business case for investment.