What Material Handling Robots Do: Applications Across Industries

The versatility of material handling automation allows robots to perform a wide variety of tasks, increasing customer satisfaction by enhancing workflow efficiency and precision.

Palletising and Depalletising: Robots automate stacking and unstacking materials on pallets, providing a more efficient alternative to traditional conveyor systems. LAC Conveyors specialises in robotic heavy lifting and palletising solutions that maximise throughput and minimise material waste, reducing operational costs.

Pick and Place Operations: Robots equipped with specialised grippers can precisely pick up items and place them into processing machines, storage units, or packaging containers, crucial for automating assembly lines and dense storage. This capability enhances inventory management by improving tracking and accuracy.

Goods Transport and Logistics: A fleet of AMRs can transport goods between different locations within a warehouse or factory, streamlining the flow of materials and reducing reliance on manual labour. LAC Conveyors offers tailored automated material transport solutions that enhance overall efficiency and improve customer satisfaction by reducing delays in delivery.

When Material Handling Robots Are Used: Ideal Applications

Material handling robots are particularly well-suited for:

Manufacturing: Robots handle both hazardous and delicate materials with speed, precision, and consistency, automating tasks such as loading/unloading machines, transporting bulk materials, and integrating with material handling systems in industrial settings.

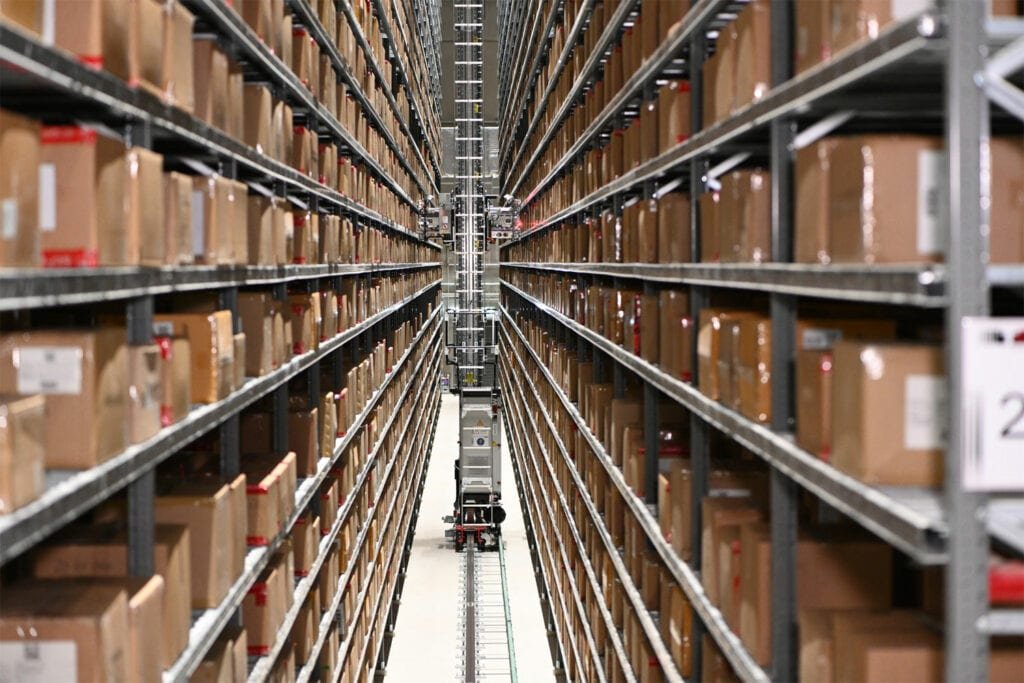

Warehousing and Distribution: Robots play a key role in material handling within distribution centres, improving order fulfilment speed, reducing errors, and optimising warehouse space utilisation with high-density storage solutions. Their integration supports digital transformation by leveraging real-time data to enhance inventory management.

E-commerce Fulfillment Centres: With the rise of online shopping, e-commerce fulfillment centres rely on automation to meet growing demands. Material handling robots optimise picking, sorting, and packing processes, ensuring seamless operations and reducing energy consumption through efficient routing and intelligent power management.

Factors to Consider When Choosing Material Handling Robots

Selecting the right material handling robot requires careful consideration of several key components:

Payload Capacity: The maximum weight of heavy material that the robot can safely lift and transport within material handling operations.

Speed and Throughput: The rate at which the robot moves materials, impacting overall efficiency and response times in a competitive environment.

Integration with Existing Systems: The ability to integrate seamlessly with warehouse management systems (WMS), current infrastructure, and storage systems.

Energy Consumption: Understanding power requirements is essential to balancing efficiency with sustainability, especially in large-scale industrial settings.

Predictive Maintenance & Equipment Failures: The ability to monitor potential equipment failures and proactively address maintenance issues helps prevent costly disruptions.