Key Use Cases for Robotic Warehouse Systems

Order Picking: Robotic picking arms and goods-to-person technology streamline the picking process, reducing travel time and human error.

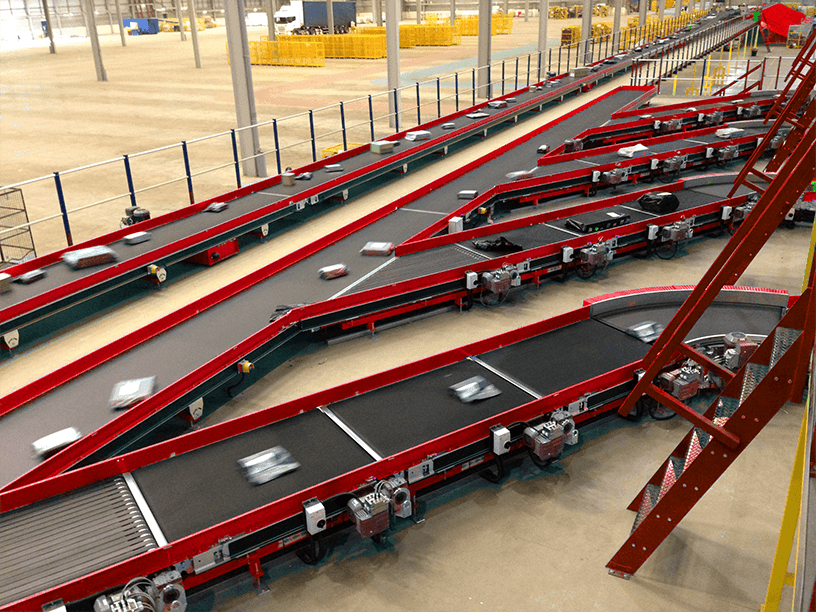

Sorting and Routing: Robots sort packages by size, weight, or delivery destination with high accuracy, supporting large-scale order fulfilment operations.

Loading and Unloading: Automated robots manage pallet loading and truck unloading tasks, optimising the use of vertical space and floor area.

Inventory Management: Advanced robotics combined with AI and machine learning enable real-time tracking of inventory levels and stock rotation.

Returns Handling: Robotic systems manage reverse logistics by sorting, repackaging, or restocking returned goods.

These applications are vital to maintaining an efficient supply chain and optimising warehouse work in today’s fulfilment environments.

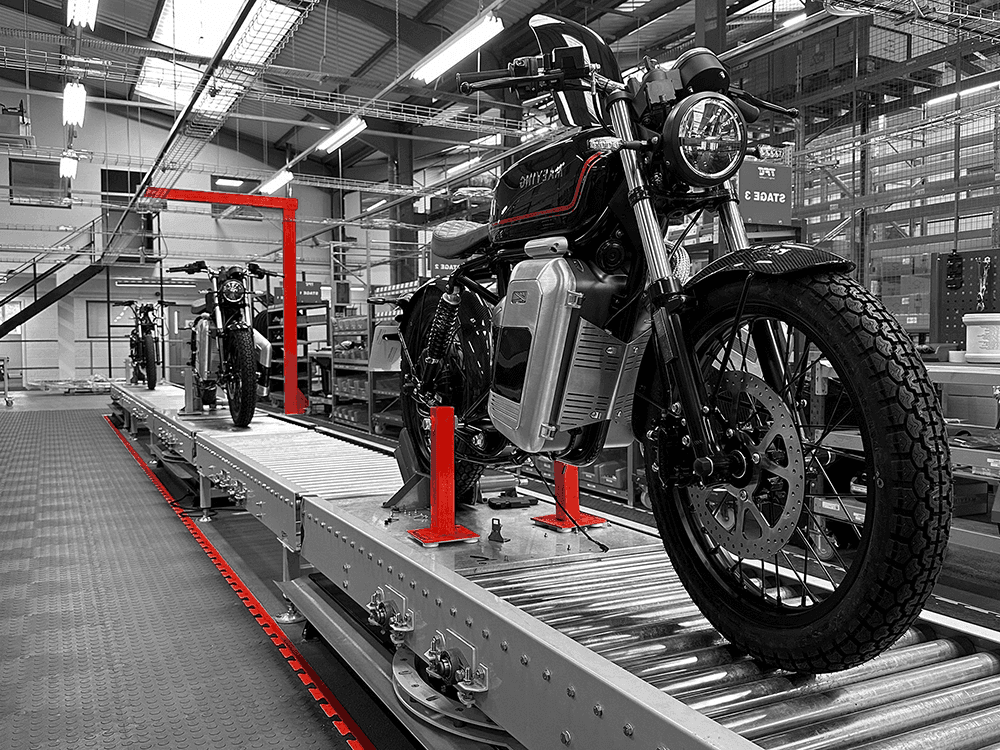

Integrating Robotics with Conveyor Systems and ASRS

Successful warehouse automation depends on seamless integration between robotics and the wider infrastructure. At L-A-C, robotic automation systems are often combined with:

- Conveyor belt systems to move items across packing, sorting, or staging areas

- Automated Storage and Retrieval Systems (ASRS) to manage bin or pallet-level storage in high-density zones

- Warehouse Management Systems (WMS) to coordinate robot actions, order picking, and inventory control in real-time

- Advanced Vision systems for object detection, barcode reading, and obstacle avoidance

By aligning robotics in warehouse management with data-rich WMS platforms and flexible conveyor solutions, L-A-C delivers scalable automation technology across fulfilment centres and distribution hubs.