How Applications Differ by Industry

With an array of robotic solutions available, it’s important to select the type of robot that is best suited to your industry requirements, to ensure it delivers optimum efficiency and flexibility. Here, we highlight different types of applications within key industry sectors:

Retail & E-commerce

Automation in retail are driven by the need for speed, accuracy, and scalability. Robots are typically used for packaging, order picking, and inventory management tasks. AMRs and AGVs help optimise fulfilment centres, while cobots can be deployed to assist with packaging and returns processing.

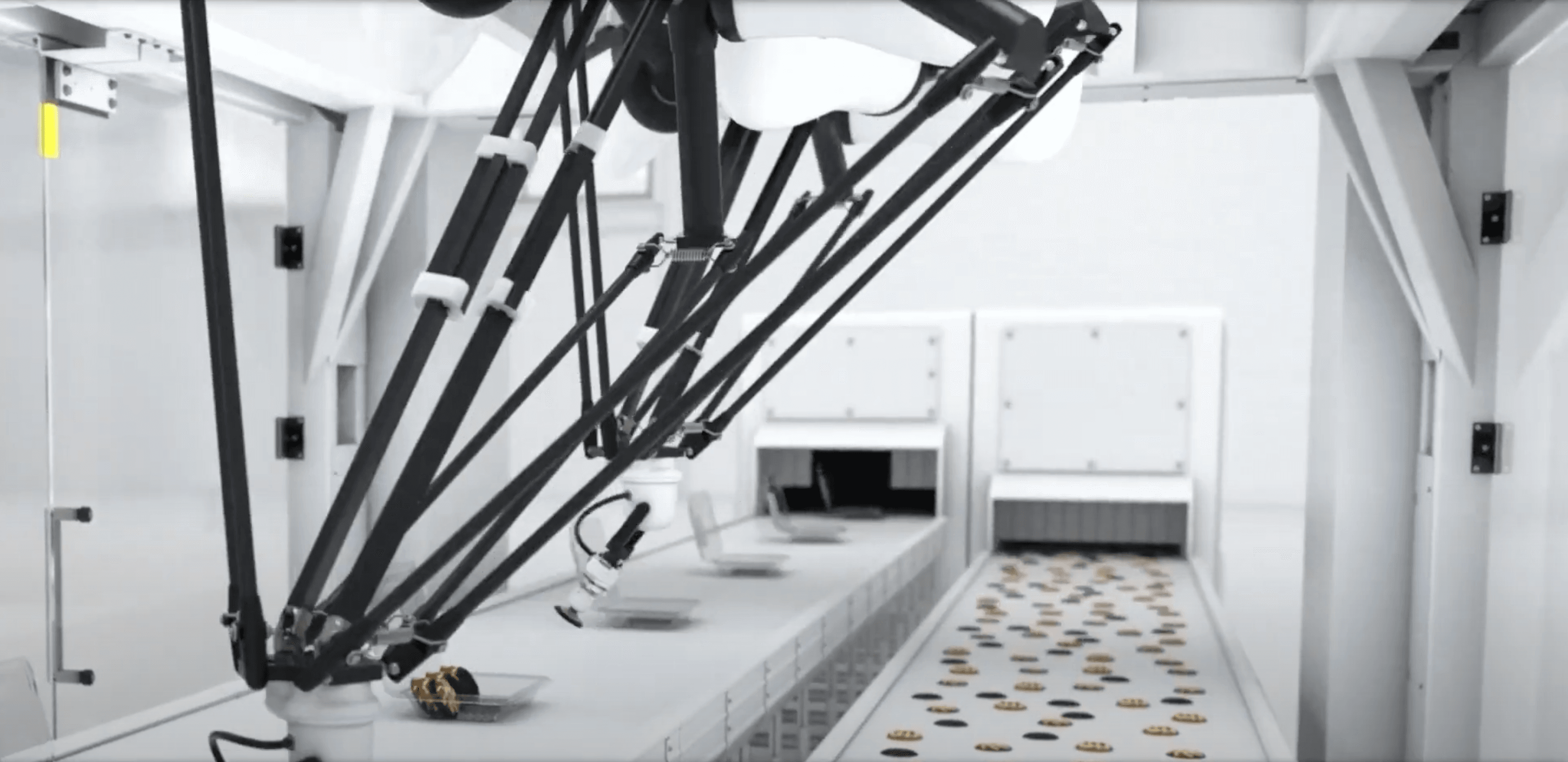

Food & Beverage

Food and beverage manufacturing prioritises hygiene and product integrity at every stage of production. Robots used in this sector must be robust, easy to clean, and fully compliant with food safety standards. Delta robots excel at high-speed sorting and packaging, while robot palletisers manage repetitive tasks without compromising the quality of the packaging.

Manufacturing

Manufacturing in the UK faces global competition and labour shortages, making robotics essential for maintaining operational efficiency. Industrial robots take on heavy-duty tasks such as welding and assembly, while AGVs and AMRs keep materials moving smoothly through the facility, boosting productivity and minimising downtime.

Pharmaceuticals

Pharmaceuticals demand precision and strict compliance with regulations. Cleanroom-rated robots are widely used for packaging, lab automation, and medical device assembly, while SCARA robots deliver high-accuracy performance. Cobots add flexibility for small-batch production, supporting efficiency and adaptability in pharmaceutical operations.