What Is Mixed Load Palletising?

Growing in popularity due to the sheer volume of SKU handling needed to cope with today’s consumer needs, mixed load palletising refers to the automation of palletising tasks where the load consists of a variety of different product types, sizes, shapes, and weights – often in the same palletising cycle. Rather than stacking identical boxes, the system must intelligently place differing items in a way that maintains center of gravity and packing efficiency.

What Are Variable Load Patterns?

Variable load patterns arise when pallets must be built from products with differing factors such as dimensions (height, width, depth), weights, fragility, stacking preferences or restrictions (e.g. heavy items on the bottom, fragile goods on top), and SKU combinations required by retailers or customers. These variable patterns are common in industries where orders are tailored or consumer choice is vast, leading to mixed case pallets being a common solution.

Why Is Mixed Load Palletising Ideal for Complex Load Patterns?

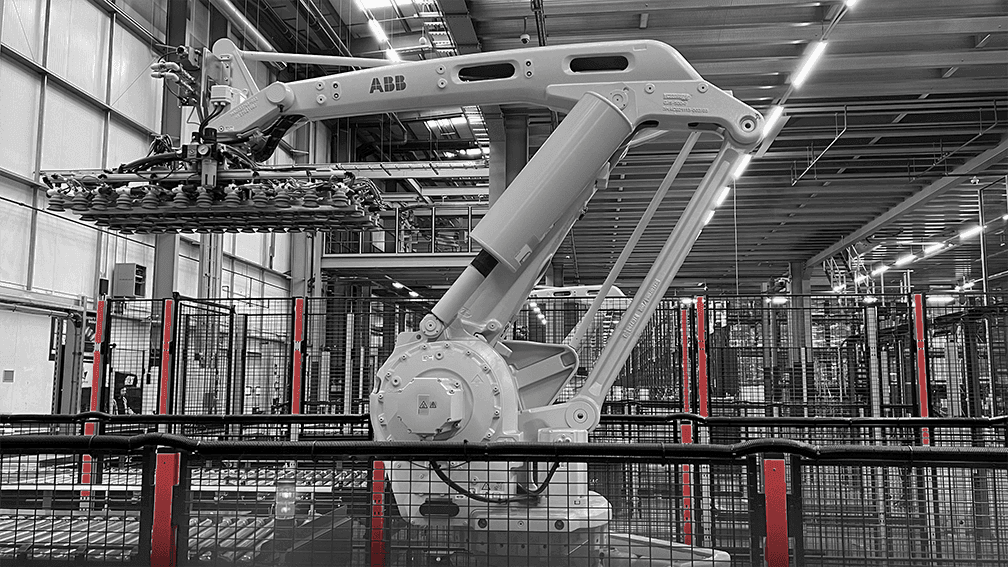

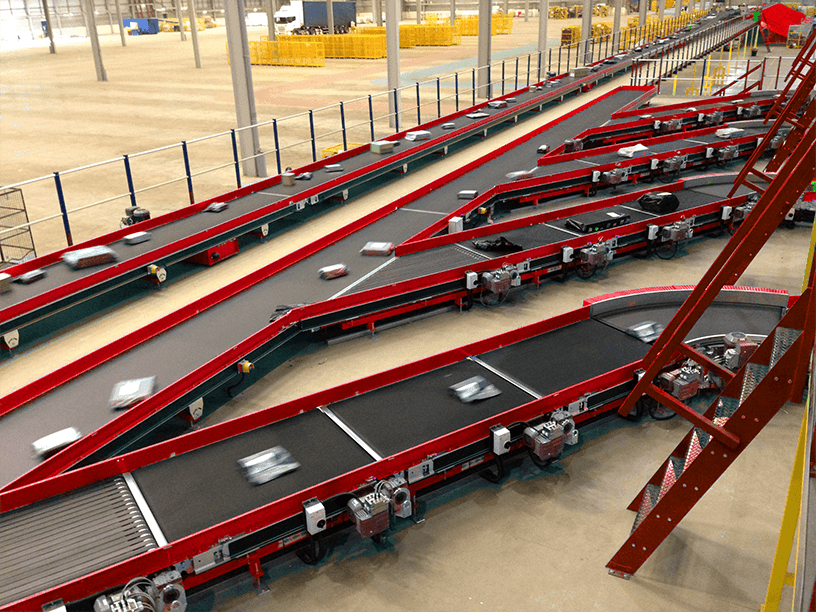

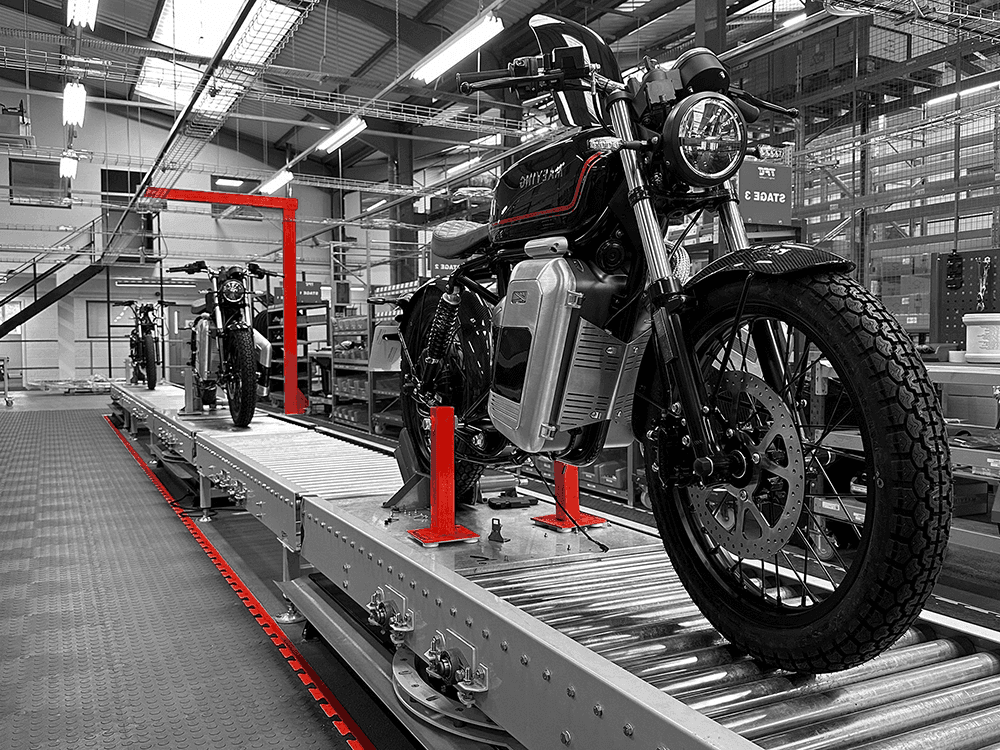

Mixed load palletisers use a combination of advanced technologies, including vision systems, robotic technology, AI, and powerful software solutions, to identify, assess, and handle products individually and arrange them in the most stable and space-optimised manner. These robotic systems create stable pallets that improve load integrity and enable safer transportation.

This makes them suitable for handling high SKU variability, customised or store-specific pallet configurations, frequent changeovers without downtime, and distribution environments requiring a high level of flexibility.