Exploring Humanoid, Warehouse, and Logistics Robots

Typically, robots used in a logistics setting can be categorised into three main types: humanoid robots, warehouse robots, and logistics robots. Each type of robot is designed to meet specific operational needs, showcasing unique attributes and capabilities, and the decision to select the most appropriate option is dependent on its precise usage.

Humanoid robots

Humanoid robots are designed to mimic human appearance and movements. They often feature arms, legs, and heads, which provide the necessary dexterity to perform tasks traditionally carried out by humans. These robots are equipped with advanced sensors, cameras, and AI-driven decision-making systems, enabling them to interact with their environment and provide valuable judgments based on real-time activity and data. The humanoid form factor and human shape also support deployment in spaces designed for human labour.

Their capabilities can include speech and gesture-based communication to replicate human habits, complex motor skills for picking or placing items, autonomous navigation in dynamic environments, and human-like adaptability to operational changes. Some even incorporate facial recognition for interacting with humans by humans.

Humanoid robots have primarily been used in more customer-facing scenarios within logistics, such as guiding visitors in warehouses or providing real-time updates to customers. However, their role is evolving at pace to include tasks such as assisting with inventory levels, picking, sorting, and stacking goods for efficient order fulfilment and shipping.

Warehouse Robots

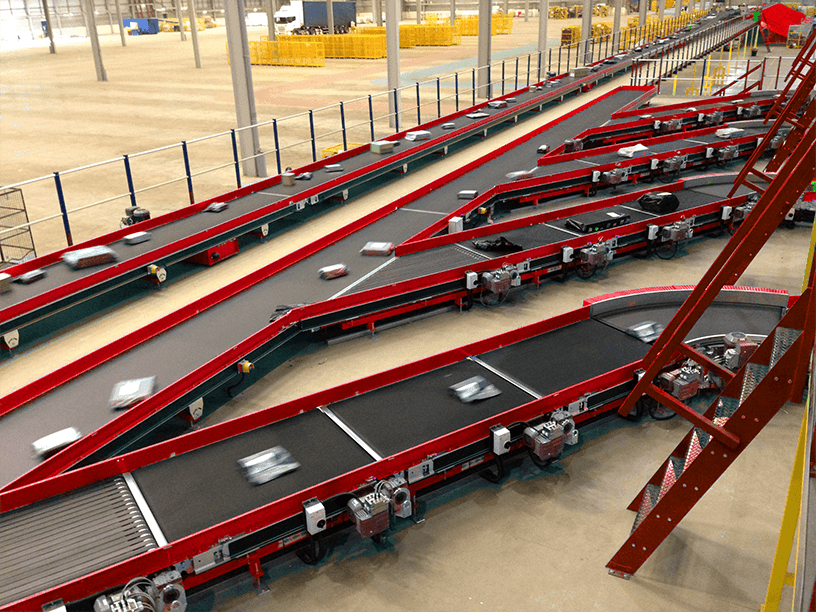

Warehouse robots are specialised machines designed to optimise storage, inventory, and order fulfilment processes. They are highly efficient in structured environments like warehouses and distribution centers, offering high-speed picking and packing, automated sorting systems, real-time inventory tracking, and integration with warehouse management systems. These warehouse robotics solutions significantly enhance warehouse productivity and accuracy in warehouse operations.

Warehouse robots can be fixed or autonomous. The most common include Automated Storage and Retrieval Systems (ASRS), Automated Guided Vehicles (AGVs), and Autonomous Mobile Robots (AMRs) for activities that include order picking, replenishment, goods-to-person movements, as well as sorting and transporting goods to dispatch areas, ready for shipment. These robotic solutions handle a wide range of stock, heavy stock, and help monitor stock levels across various storage locations.

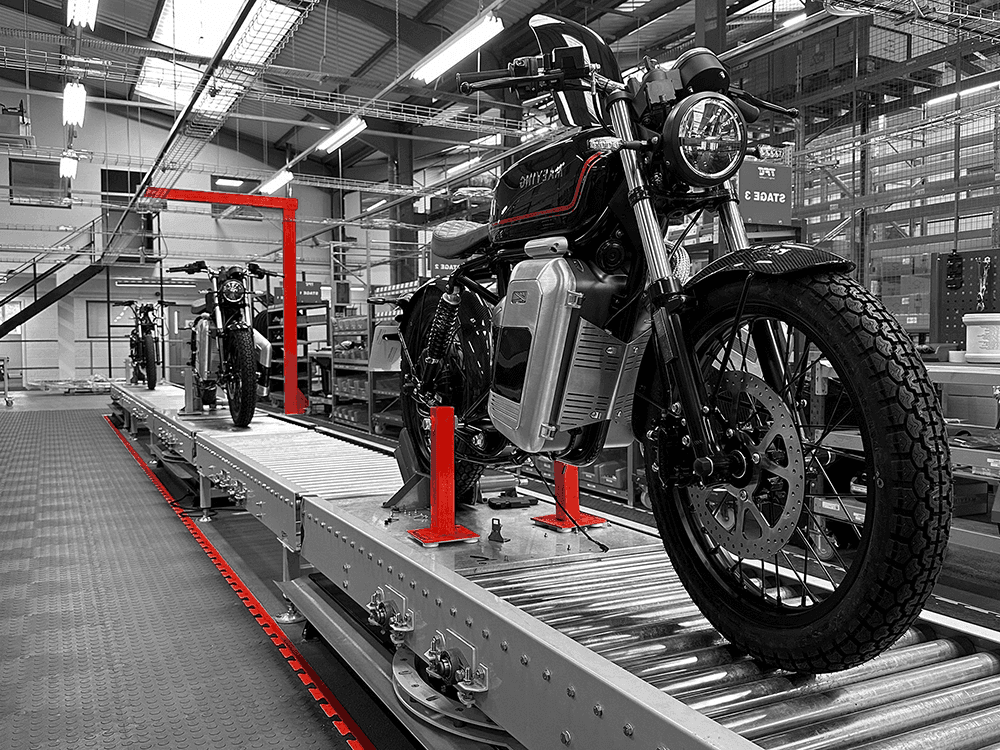

Logistics Robots

Logistics robots often overlap with the range of warehouse robots but focus more on end-to-end supply chain operations. So, whilst they are commonly used in warehouses and storage facilities, they can also be found in shipping hubs and delivery fleets. Logistics robots are designed to handle transportation and delivery tasks with precision, often using autonomous navigation. These autonomous robots offer the ability to load and unload goods efficiently and provide fleet management with optimised routing using AI-based analytics to reduce delivery times and improve customer satisfaction.