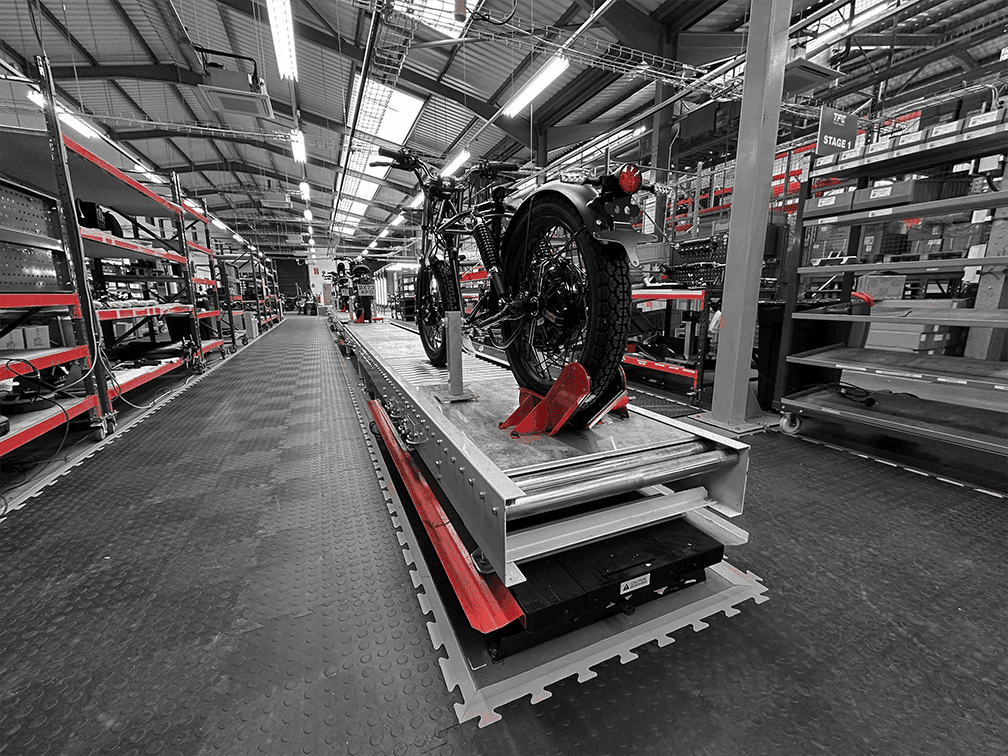

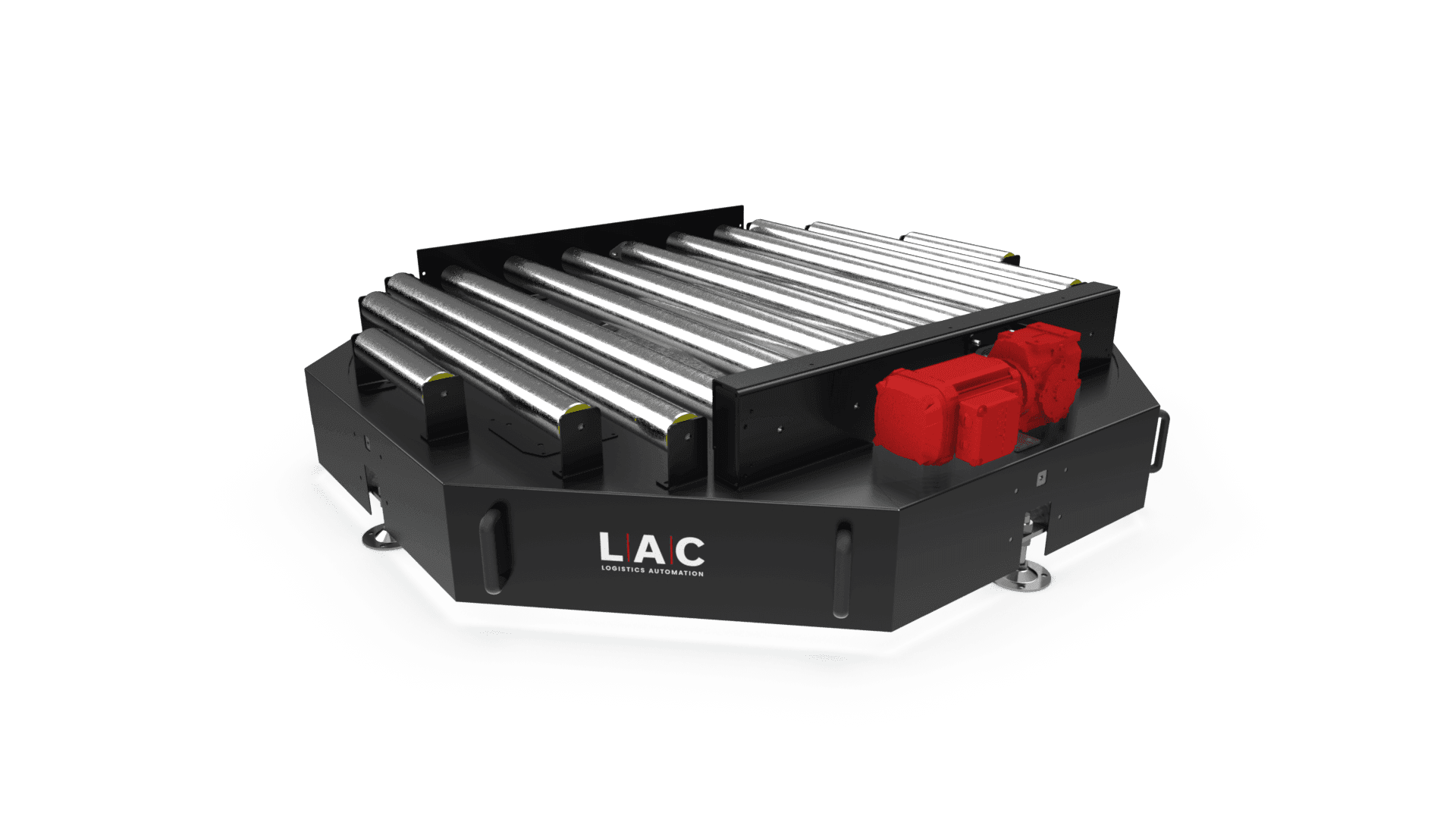

In modern warehouse settings, where adaptability and performance are key, L-A-C provides tailored designs to meet the specific requirements of your operation. We offer bespoke conveyor solutions, including bespoke conveyor systems and conveyor for carton transport, built to enhance productivity. Our vertical conveyor systems and roller conveyors are engineered to improve the efficiency of your distribution centres and fulfilment operations, ensuring your business thrives in an increasingly competitive marketplace.

With conveyor handling materials systems, such as curing conveyor systems and conveyor for access modules, we ensure a seamless flow of products. We also offer conveyor installation services and conveyor units like baggage conveyor belts to meet a wide variety of needs. Our conveyor roller manufacturer expertise ensures that each system is built to the highest standards, offering bespoke belt conveyor solutions for a range of industries.

Purchase a conveyor system for my business

When selecting a conveyor system for your business, it's crucial to consider the type of material being handled and how it integrates with your logistics processes. L-A-C offers a wide range of conveyor types at competitive prices, ensuring that every system is designed to meet your individual requirements. Our solutions are crafted to enhance operational efficiency and maximise customer satisfaction. Make an informed decision today and invest in a conveyor system tailored to your needs. Contact us to explore how our bespoke conveyor solutions can streamline your operations.