Implementing camera inspection conveyors delivers a host of benefits for manufacturers, from waste reduction and improved product quality to enhanced throughput and data collection for traceability. Here are some of the key benefits:

Production Efficiency & Accuracy

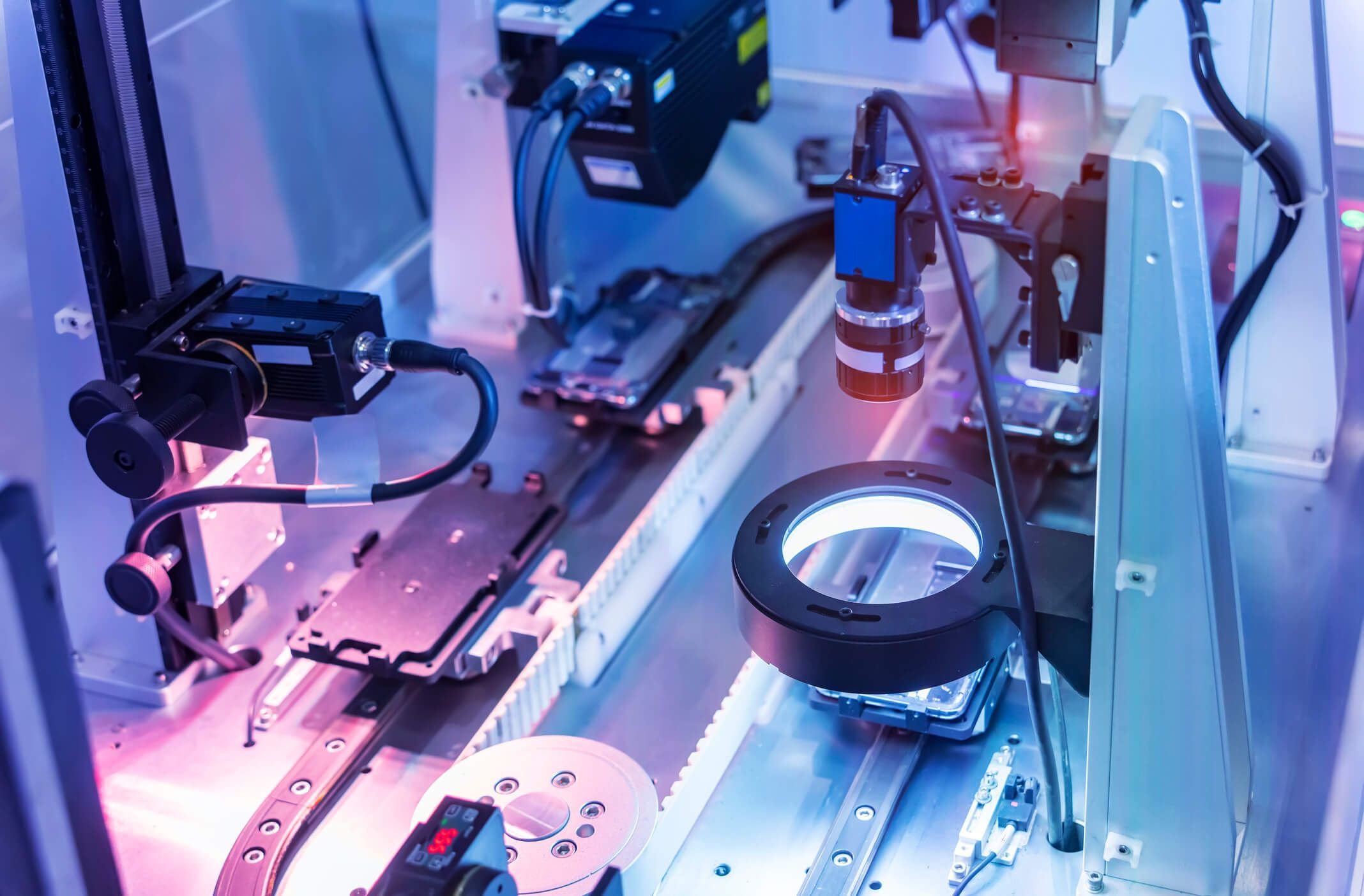

Elevated Product Quality - Real-time camera inspection identifies defects the moment they occur, eliminating the risk of producing hundreds or even thousands of faulty units before an error is detected. This ensures only products that meet stringent standards leave the production line, raising customer satisfaction and reducing the costly and time-consuming process of goods being returned.

Real-Time Line Correction - Integration with PLCs (programmable logic controllers) allows systems to automatically adjust processes in response to detected errors, such as correcting label placement or pausing a filling station when volume anomalies are found. This enables faster resolution of the root cause of issues and reduces costly downtime.

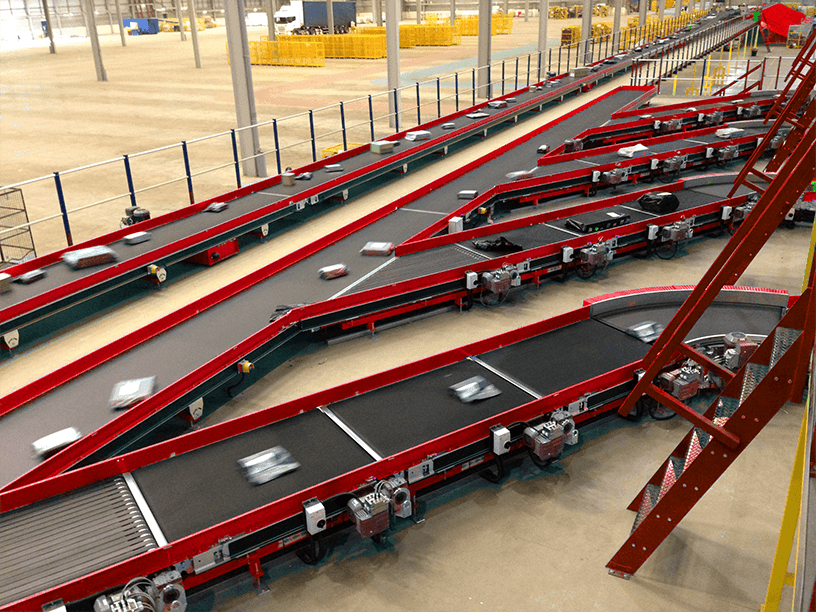

Faster Throughput - Automated inspections are significantly faster than manual inspections. By automating the visual element of the overall inspection process, this provides improved production efficiency and increased volume of product checks on production or sortation lines.

Compliance, Safety & Traceability

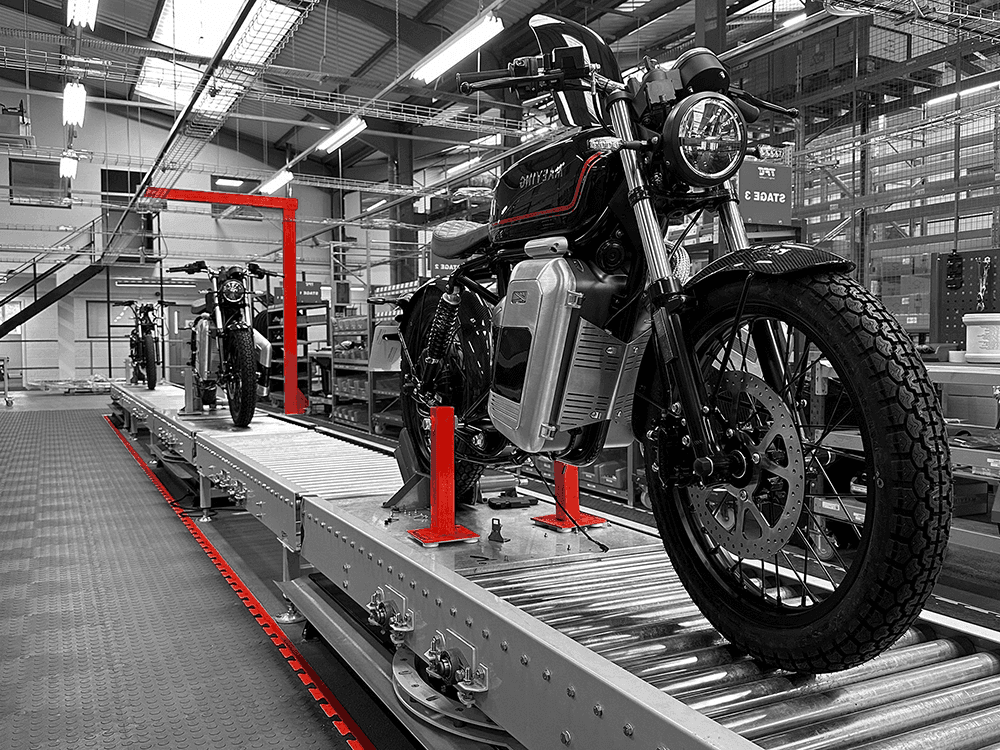

Automated Compliance & Traceability - With increasing demand for digital traceability, camera inspection systems provide image-based archives, error logs, and inspection reports. This helps support compliance with strict food and pharmaceutical regulations, in place to ensure the safe production and handling of goods.

Smart Data Collection - Modern inspection systems go beyond their designated visual or scanning tasks by collating vital data. Integrating vision inspection with software solutions, including WMS (Warehouse Management Systems), MES (Manufacturing Execution Systems), and ERP (Enterprise Resource Planning) platforms, enhances operations from general process improvements to more specific actions such as predictive maintenance, based on accurate, real-time data quality.

Enhanced Brand Protection - Consistently delivering defect-free products helps protect product integrity and supports a strong brand reputation. With instant defect rejection and 24/7 monitoring along a conveyor line, only goods that meet the required standard leave the production or storage facility.

Operational Cost Savings & Workforce Health

Waste Reduction - By instantly identifying non-conformities, manufacturers can stop or reroute affected products before they reach final packaging or shipment. In industries such as food or pharma, this reduces spoilage, saves material costs, and supports sustainability goals.

Labour Cost Savings & Health - While human inspectors may tire or miss subtle defects, vision systems can operate 24/7 without fatigue, achieving greater accuracy at scale. Manual workers can be reallocated to higher-value roles, such as process optimisation or maintenance, and avoid repetitive or physically demanding inspection tasks that could lead to injury.

Together, these benefits demonstrate how real-time camera inspection not only safeguards product quality and compliance but also drives greater efficiency, cost savings, and long-term operational resilience.