The versatility of conveyor system solutions continues to evolve at pace, driven by advances in technology. From AI to Robotics, here are some of the key trends to watch in 2025:

Smart Conveyors

- Integration of IoT for real-time monitoring and diagnostics.

- Predictive conveyor system maintenance using AI.

Automation and Robotics

- Combining conveyors with robotic systems for advanced material handling.

- Integration of autonomous mobile robots (AMRs) to complement operational processes using conveyor systems.

Modular Designs

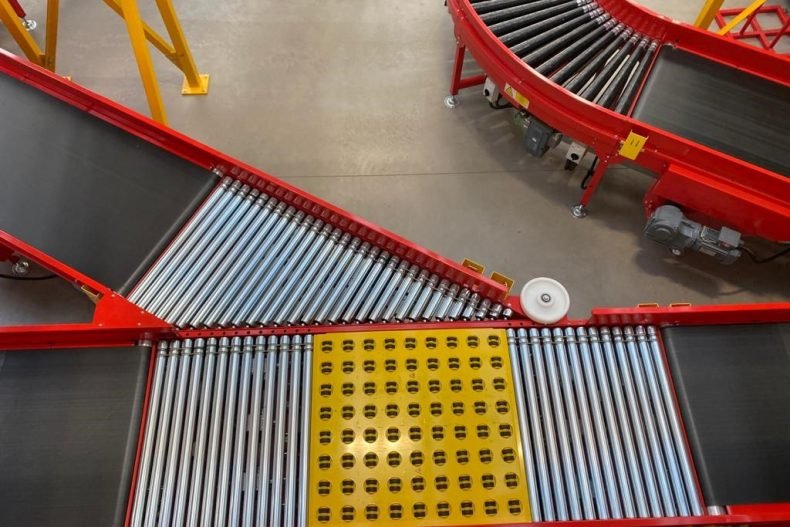

- Increased use of modular components for straightforward customisation and scalability.

- Plug-and-play systems offering quick installation.

Energy Efficiency

- Adoption of energy-efficient motors and regenerative braking systems.

- Solar-powered conveyors for eco-friendly operations.

Advanced Materials

- Development of lightweight yet durable materials.

- Enhanced corrosion resistance and hygiene standards for food and pharmaceutical applications.

Making the Right Choice for Your Business

With the various benefits and considerations outlined above, making the final decision between custom and standard conveyor systems can seem overwhelming. To help with this process, we have put together a summary of the factors to consider to ensure the best use of investment for your conveyor system. A reliable conveyor manufacturer will provide guidance tailored to your operational needs.

For operational needs, analyse your workflow, material types and requirements for volume. Also, factor in expansion and diversification plans here. When it comes to the all-important budget, determine your up-front investment capital versus the long-term savings, enhanced productivity, and throughput to determine ROI. When looking at the flexibility needed for the conveyor system, assess the level of customisation your operations demand and if bespoke elements can be retrofitted to a standard solution, should the need arise in the future. Scalability and understanding future needs are a vital part of the decision process to ensure the chosen solution delivers efficiency now and in the long term. For applications with strict industry standards, the conveyor system must enable your operations to comply with industry-specific regulations and standards. Conveyor flexibility will be critical in adapting to these evolving needs.