The Importance of Conveyor Systems with Integrated Safety

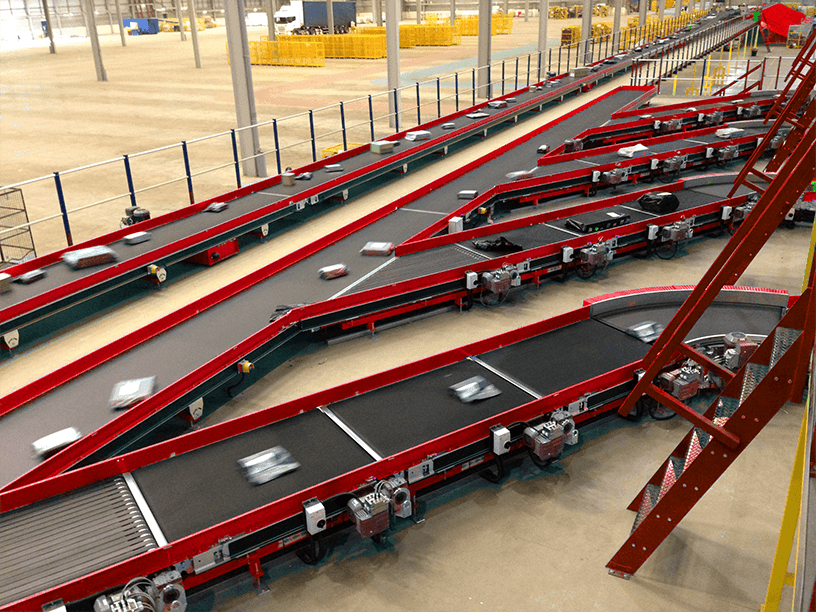

According to the Health and Safety Executive (HSE), there were 561,000 non-fatal injuries reported by UK workers in 2022/23, with a significant number occurring in warehousing and manufacturing sectors. Manual handling remains one of the top causes of workplace injury, often from repetitive tasks or heavy lifting. Conveyor systems are designed to help minimise this risk by reducing the need for workers to lift, carry, or move heavy or awkward loads manually, thus addressing common hazards.

Conveyor Safety Measures: Protecting People and Processes

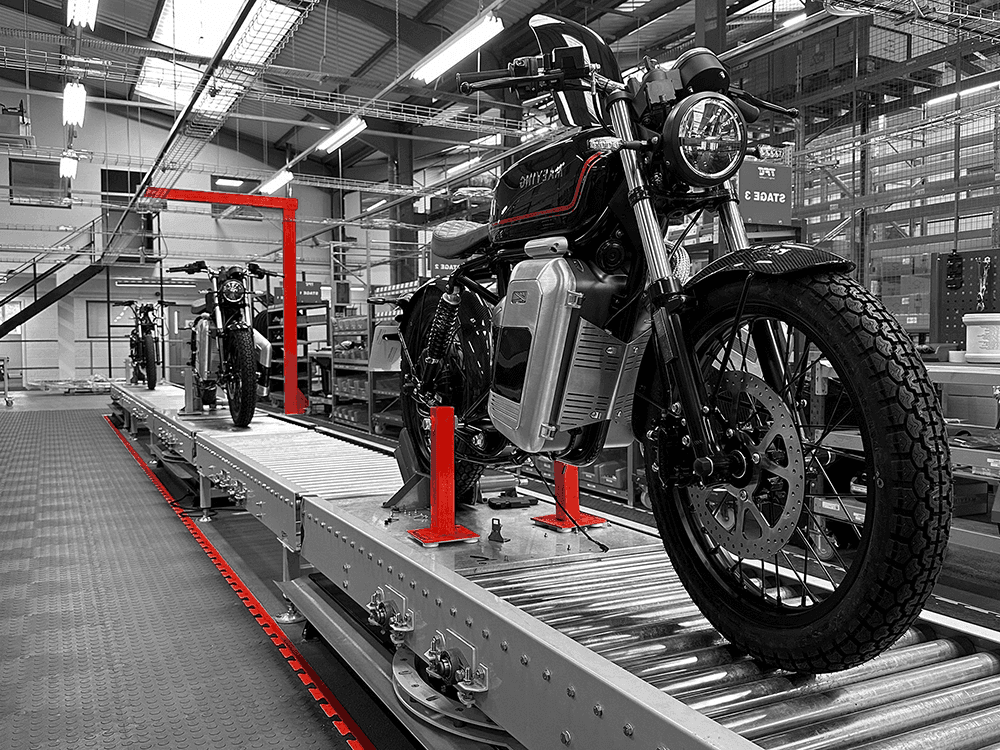

Modern conveyor systems have been the beneficiary of enhanced engineering over the years, now providing a highly efficient combination of streamlined material handling with considerable safety features as standard. Some of the key conveyor safety tips and features include:

- Emergency stop buttons placed strategically along conveyor lines.

- Conveyor guards and covers to prevent operator contact with moving parts.

- Interlocking mechanisms to shut down the conveyor when a hazard is detected.

- Conveyor controls and speed limiters to prevent unsafe conditions.

- Visible warning systems and audible warning signals to alert staff of changes.

- Automatic load detection systems to monitor load capacity and avoid overloading.

Implementing these features supports safe operations and helps reduce conveyor belt accidents and injuries from tasks on conveyor belts.