Conveyor System Applications for Industry

Conveyor systems play a crucial role across a wide range of industries, offering cost-effective solutions that improve productivity, safety, and overall operational efficiency. By automating material movement, reducing manual labour, and optimising workflows, businesses can achieve significant efficiency gains and maintain a strong competitive edge. Below, we explore how various conveyor types are applied in different sectors to address unique challenges and enhance production processes.

Automotive Industry

In the automotive sector, conveyor equipment is integral to assembly lines, where precision, speed, and handling of heavy loads are critical. Overhead conveyors enable smooth movement of parts, freeing up valuable warehouse space and ensuring a more efficient assembly process. Chain conveyors are widely used to transport bulk materials such as vehicle frames and large components, reducing reliance on manual labour while enhancing improved safety.

Furthermore, the integration of warehouse management systems and warehouse automation solutions enables seamless tracking and handling of components. By minimising risk of errors and improving processing times, automotive facilities achieve enhanced control systems for parts delivery, resulting in higher customer satisfaction and streamlined workflows.

Food and Beverage Industry

The food and beverage industry requires highly hygienic and efficient material handling solutions. Belt conveyors are essential for transporting packaged and unpackaged products, ensuring smooth movement across production phases such as cutting, cooking, and packing. Pneumatic conveyors are ideal for handling bulk materials like grains, flour, and powders in a fully enclosed system, reducing contamination risks and enhancing improved safety.

Modular conveyors, equipped with easy-to-clean plastic belts, offer long-term benefits by simplifying regular maintenance and supporting strict hygiene standards. These systems optimise warehouse operations by reducing manual labour while maintaining precise material movement for quality control. The food sector also benefits from cost-effective solutions that deliver a strong return on investment through increased throughput and reduced waste.

Pharmaceutical Industry

The pharmaceutical industry demands accuracy, efficiency, and compliance with stringent regulations. Modular conveyors ensure precise material movement of medicines and delicate components, reducing the need for human intervention and improving enhanced safety. Belt conveyors, designed for minimal disruption, optimise processing times while ensuring the integrity of critical products.

Pneumatic conveyors are commonly used for bulk material handling in pharmaceutical powder production, minimising contamination risks and offering reliable warehouse automation solutions. These systems are designed for optimal performance and are easy to adapt, ensuring facilities can meet growing production demands while reducing labour costs and enhancing customer satisfaction.

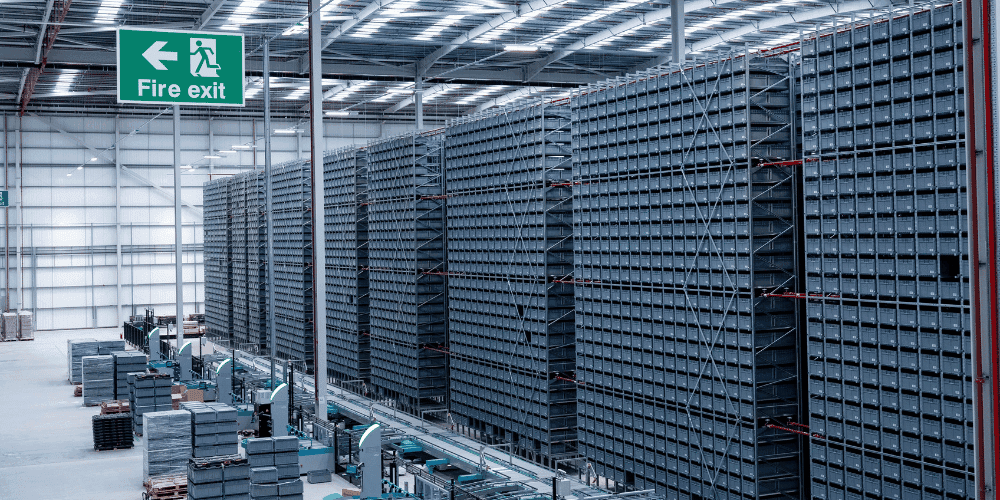

Logistics and Warehousing

Conveyor systems are at the heart of modern warehouse automation, enabling faster, safer, and more accurate fulfilment processes. Roller conveyors and gravity roller conveyors are widely used for sorting, picking, and transporting goods, improving processing times and reducing labour costs.

Integrating conveyors with control systems, robotic palletisers, and warehouse management systems enhances productivity by automating repetitive tasks and ensuring the efficient handling of heavy loads. Businesses benefit from maximised warehouse space, reduced reliance on manual labour, and increased efficiency gains that support future growth. By optimising workflows, logistics facilities gain a significant competitive edge in meeting high-demand operations.

Mining and Quarrying

In the mining and quarrying industries, screw conveyors and chain conveyors play a pivotal role in transporting bulk materials such as coal, minerals, and aggregates. These robust systems are engineered to handle heavy loads over long distances, improving material movement efficiency while reducing reliance on manual labour.

With their ability to operate in high-stress environments, chain and screw conveyors ensure enhanced safety, protecting workers from hazardous conditions. These systems also offer cost-effective solutions that minimise downtime and operational costs, providing businesses with a strong return on investment and long-term benefits.

Electronics Manufacturing

In the electronics industry, modular conveyors are essential for the precise handling of delicate components. These systems support smooth movement with minimal disruption, ensuring efficient assembly while reducing risk of errors. Modular designs allow for quick reconfiguration, meeting the industry’s need for adaptability and optimal performance.

Electronics manufacturing facilities benefit from warehouse automation solutions that integrate conveyors with control systems for enhanced precision and accuracy. This reduces processing times, maximises warehouse space, and ensures consistent material movement, all while lowering labour costs and improving customer satisfaction.

E-commerce and Retail Fulfilment

The rise of e-commerce has increased the demand for efficient fulfilment processes and rapid order delivery. Conveyor equipment, such as belt and roller conveyors, enables seamless sorting, packing, and shipping of goods. By automating material handling solutions, businesses achieve faster processing times while reducing reliance on human intervention.

Integrated control systems and warehouse management systems ensure efficient tracking and handling of orders, enhancing customer satisfaction through accurate and timely deliveries. These systems provide a scalable, cost-effective solution for businesses looking to meet growing consumer demands and maintain a competitive edge in the market.