The most common carcass materials to be used are steel, polyester, nylon, cotton, and aramid while the covers are usually various rubber or plastic compounds specified by the use of the belt. If the conveyor system is carrying heavy goods, steel conveyors can be used due to their high strength and increased durability. The steel conveyor belts are made of steel cords compared to the lower class strength ones that use polyester, nylon, and cotton. The lower strength the material used or conveyor system installed will reduce the amount of energy consumed for operation while also increasing the product life and enhance productivity. A fundamental part of a conveyor system to ensure the smooth running is a Drive Arrangement, which comprises of Gear Boxes, Drive Motors, and associated couplings. On top of this, there are several parts that can be used or are needed for a functioning conveyor system.

Scrapes are used to clean the belt, chutes control the discharge direction, and Skirts are for containing the discharge on the receiving belt, Take Up assembly for “tensioning” the belt and Technological Structures like Stringer, Short Post, Drive Frames, and Pulley Frames make up the balance items to give you a full operating belt conveying system. Within the food industry, you will see conveyors in a blue material. This means they are washable, also known as wash-downable, in order to comply with hygiene laws for food.

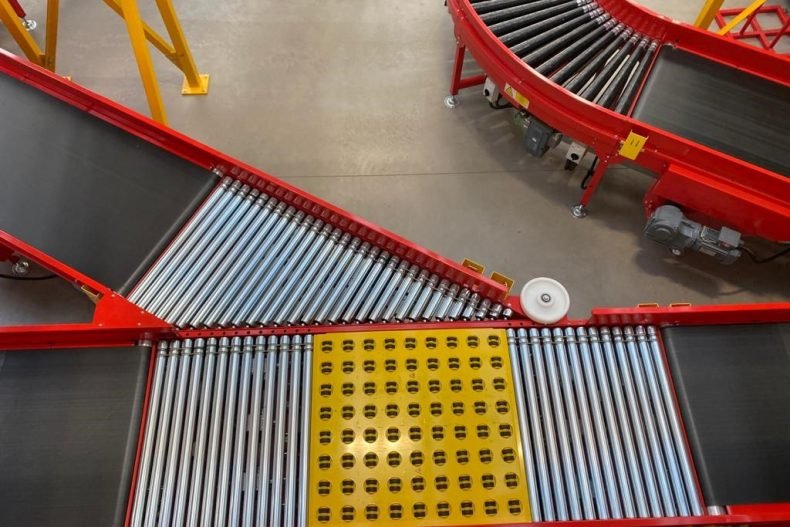

A conveyor belt is a critical component in various industrial applications, facilitating the efficient transport of loose materials and heavy-duty items across different stages of production and distribution centres. At LAC Logistics Solutions, we offer a wide selection of belt conveyors designed to meet exact requirements, including medium duty belt conveyors, incline belt conveyors, and portable conveyors. Our products feature robust construction using materials like stainless steel, mild steel, and high-quality rubber conveyor belts, ensuring durability and reliability.