Complete Multi-Level Warehouse Conveyor Systems

Improving warehouse efficiency and productivity while minimising costs can be a challenging endeavour. Integrating a warehouse conveyor system into your operations can provide a substantial boost to your material handling processes. By adopting a multi-level conveyor solution, businesses are afforded the flexibility to scale their distribution centres or manufacturing facilities in a way that aligns with their growth and budgetary constraints.

Whether you’re upgrading an existing facility or establishing a new one, the strategic implementation of a multi-level conveyor can drastically transform your productivity. It streamlines the movement of goods by providing a continuous flow from receiving to shipping, reducing manual handling and the associated labour costs. By ensuring that products can be transported efficiently across multiple levels, from the ground to the upper tiers of storage, the conveyor system maximises vertical space, which is often underutilised in warehouse settings.

The automated nature of these systems helps reduce errors, improve sortation accuracy, and increase the speed of throughput, which in turn diminishes dwell time and accelerates delivery. With a complete warehouse automation solution, you position your operations to handle peak demands with ease, fostering a more resilient and responsive supply chain infrastructure.

What is a Multi-Level Conveyor System?

A multi-level conveyor system is a warehouse solution which consists of a series of conveyor belts used to transport products between floor levels. It is designed to reduce the distance that operational staff would have to walk and in turn, increase productivity. These conveyor systems are commonly used for beauty products, books, sportswear and automotive products.

What are the Benefits of Multi-Level Warehouse Conveyor Systems?

There are several benefits to installing multi-level conveyor solutions in a warehouse, including:

- Improved safety of the warehouse, including eliminating the need to use forklifts on mezzanine floors

- Increased picking efficiency and productivity due to less walking required from warehouse staff

- Automated stock management and replenishment when stock is low

- Automated sortation to carriers based on price, where the WCS is set with changeable parameters (e.g. weight, volume)

- The option to fit out a warehouse in gradual steps according to the business growth pattern and budget

How Do Multi-Level Warehouse Conveyor Systems Work?

Major distribution centres are typically built with very high ceilings to accommodate high bay racking which is filled with bulk or palletised products, some to up to 30m high. These high ceilings allow for multi-level mezzanine floor structures to be built which accommodate fast–moving products.

Without a conveyor system in place, operational staff would have to walk a considerable distance to keep the process moving and would have to rely on each other to be in the right place at the right place.

A multi-level warehouse conveyor solution can be designed bespoke to the requirements of the business, but its ultimate purpose is to keep the process moving and increase productivity by reducing the amount of walking required by operational staff.

The conveyor systems are integrated into the warehouse control systems (WCS) and warehouse management systems (WMS) to achieve a fully functioning high-speed intralogistics solution. The warehouse management system (WMS) will monitor incoming business orders and automatically place a replenishment order when the level of stock drops.

To replenish stock, pallets are broken down at ground level and the individual cartons are placed on a conveyor. The carton will have a barcode which is scanned at several locations along the conveyor system until it reaches the ‘bus stop’ closest to its stock location, where it will end up being diverted to a separate conveyor and waiting to be stored in its assigned area.

For packed stock exiting the warehouse, ground floor sortation will send the product out to the customer (B2B or B2C) by using the warehouse management system (WMS). This is set with changeable parameters (weight or volume), automatically selects the courier based on the best price, and sorts the parcel to them.

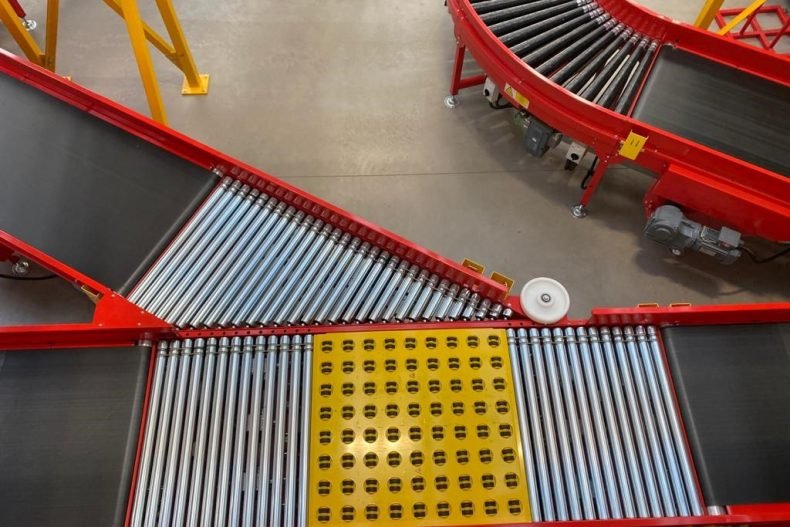

What Equipment Does a Multi-Level Conveyor Solution Include?

A complete automated multi-level warehouse solution will typically include;

Pallet conveyors

Belt conveyors

Roller conveyors

Sortation conveyors

Spirals

Goods lifts

Elevators

Mezzanine floors

Storage

Order picking systems

Want to Know More?

At L-A-C Logistics Automation, our mission is, through imaginative and blue–sky thinking, to be recognised as class–leading solution providers for materials handling and automation systems. We set ourselves apart by manufacturing our equipment in-house, in Nottingham (UK). We have been providing innovative conveyor and automation solutions to the manufacturing and logistics industry for more than two decades, gaining a breadth of experience unmatched in our industry.

Our solutions are purpose designed and built for the application, not constrained by equipment range limitations. Our expert in-house controls division understands the complexities and importance of integrating warehouse control systems (WCS) and warehouse management systems (WMS) to achieve a fully functioning high-speed intralogistics solution.

For more information, fill out our contact form or call us on 0115 975 3300 today!