Introduction

In the dynamic and ever-expanding e-commerce sector, fulfilment centres face a continuous battle to keep pace with escalating demands. The challenge is not just in handling a higher volume of orders but also in maintaining accuracy, efficiency, and speed in their operations. As consumer expectations for rapid delivery rise, fulfilment centres are increasingly pressured to optimise every aspect of their logistics processes.

L-A-C Logistics Automation, is a leader in providing cutting-edge modular conveyor solutions specifically designed for these high-demand environments. At L-A-C, we understand the unique challenges faced by busy fulfilment centres and offer modular conveyors that are not just a part of the solution but a transformative tool in streamlining and elevating the entire fulfilment process.

Our expertise and commitment to innovation place us at the forefront of logistics automation, making us the go-to partner for fulfilment centres aiming to thrive in the competitive e-commerce sector.

The Role of Modular Conveyors in Modern Fulfilment

In the dynamic industry of modern fulfilment, modular conveyors have emerged as a cornerstone technology, streamlining operations in logistics and distribution centres. These systems are designed for adaptability and scalability, essential in an industry where demands and layouts can change rapidly.

What are Modular Conveyors?

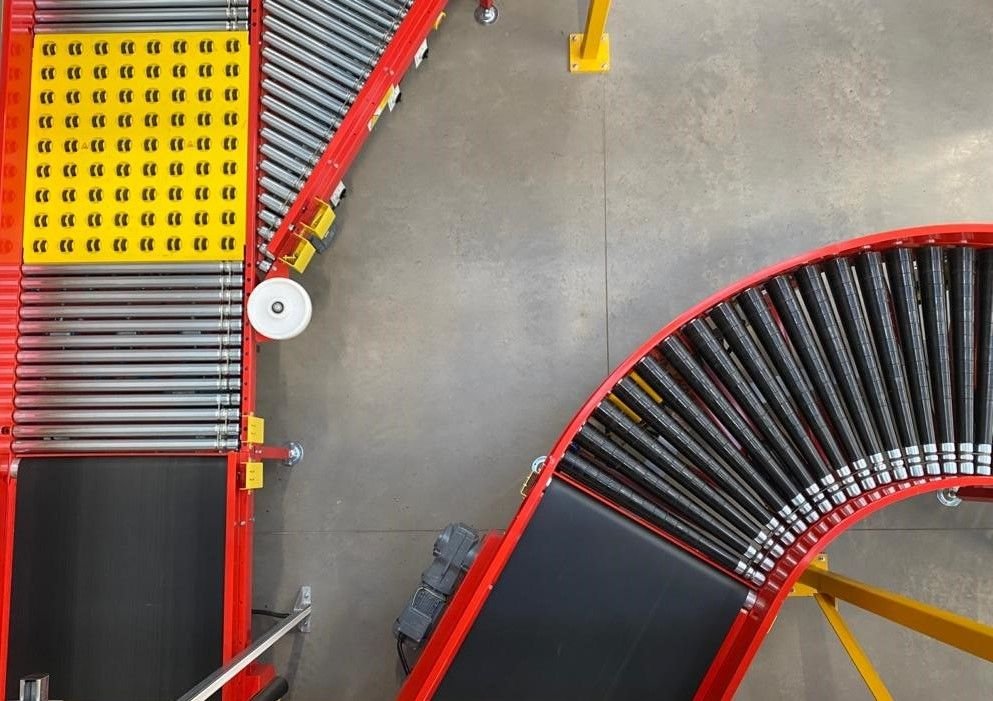

Modular conveyors also known as conveyor modules are versatile and flexible systems composed of various interlocking sections. These sections can be easily added, removed, or rearranged, allowing the conveyor system to adapt to different operational needs or physical spaces. This flexibility is vital in fulfilment centres where the layout might need to change due to seasonal demands, shifting inventory, or expansion.

Importance in Logistics

The role of modular conveyors in logistics cannot be overstated. They provide a critical solution for efficiently moving products through various stages of processing – from receiving and sorting to packaging and shipping. By enhancing material flow, these conveyors reduce manual handling, minimise errors, and speed up processing times, directly impacting productivity and operational efficiency.

L-A-C Logistics Automation’s Modular Conveyors

L-A-C Logistics Automation’s modular conveyors stand out in the sector for their innovative design and robust functionality. Our systems are engineered for maximum flexibility and durability, ensuring they can meet the diverse needs of busy fulfilment centres. With an emphasis on easy integration and user-friendly operation, our conveyors are not just a part of your logistics operations; they are a strategic asset that enhances overall efficiency and adaptability.

Through these advanced modular conveyor systems, L-A-C Logistics Automation demonstrates its commitment to providing solutions that are not just in step with the industry’s demands but are also shaping the future of logistics efficiency.

Customisation and Flexibility

Today’s fast-paced fulfilment centres need the ability to customise and adapt is crucial. L-A-C Logistics Automation understands this need and offers modular conveyors that are not just efficient but highly customisable to suit various operational demands.

Customisable Nature of L-A-C’s Modular Conveyors

Our conveyor modules are designed with customisation at their core. This flexibility allows for adjustments in length, width, and even the path they follow. Depending on the specific requirements of a fulfilment centre, these conveyors can be configured in numerous ways – from straight lines to curves, inclines, or declines. This adaptability extends to the speed and type of conveyor belt used, ensuring that each system can handle the specific types of goods moving through a centre.

Real-World Applications and Adaptations

In our collaboration with Evri, L-A-C Logistics Automation significantly improved the parcel carrier’s sortation capacity and efficiency. By customising their conveyor system and implementing conveyor modules, Evri achieved a threefold increase in sortation capacity, 99.9% accuracy in sorting, and a 50% reduction in labour costs.

The system was specifically designed to handle small-sized parcels, which were previously challenging to process. This adaptation showcases how L-A-C’s modular conveyors can be tailored to address unique challenges, leading to substantial improvements in operational efficiency.

Evri’s case study illustrates the effectiveness of L-A-C Logistics Automation’s conveyors in enhancing the productivity and scalability of fulfilment centres, adapting seamlessly to evolving business needs and space constraints.

Enhancing Efficiency with L-A-C’s Modular Conveyor Systems

Our modular conveyor system implementation is engineered to drastically improve operational efficiency in fulfilment centres. These systems are designed to streamline every phase of the logistics process, from receiving to shipping, ensuring a smoother and faster flow of goods.

The modular design of these conveyors allows for rapid adaptation to changing demands, enabling facilities to manage high volumes of goods with greater accuracy and speed. This adaptability reduces downtime and increases throughput, crucial for maintaining competitive edges in the logistics sector. By minimising manual handling and automating critical stages of the sorting and transportation process, these systems significantly cut down on errors and labour costs.

Client testimonials have consistently highlighted the efficiency gains from using L-A-C’s modular conveyor systems. Users report substantial improvements in processing times, enhanced flexibility in handling diverse product types, and a notable reduction in operational bottlenecks.

The modular conveyor solutions we provide are not just about transporting goods; they are about transforming the efficiency and productivity of fulfilment centres, ensuring that businesses are equipped to meet the challenges of today’s fast-paced logistics environment.

Scalability and Future-Proofing with L-A-C Logistics Automation

Our approach at L-A-C Logistics Automation is to provide solutions that grow with your business. Scalability is a key feature of our modular conveyors, ensuring they evolve as your fulfilment centre expands.

- Ease of Expansion: The modular nature of our conveyors means they can be easily expanded or reconfigured. This adaptability is crucial for handling increased volumes or adapting to new product types.

- Cost-Effective Upgrades: With our systems, scaling up doesn’t mean starting from scratch. You can upgrade or extend existing setups, making it a cost-effective solution.

- Staying Ahead of Market Trends: We recognise the rapid evolution of the logistics sector. Our solutions are designed not just for today’s needs, but for the demands of the future. This forward-thinking approach ensures your fulfilment centre stays competitive and efficient.

- Responsive to Change: Whether it’s a seasonal spike or long-term growth, our conveyor systems quickly adapt. This responsiveness is vital in maintaining uninterrupted operations during scale-up phases.

Partnering with us means investing in a solution that supports not just your current operations but also your future success. Our commitment is to provide scalable, adaptable, and future-proof logistics solutions.

Integration with Existing Systems

L-A-C Logistics Automation prioritises seamless integration with your existing logistics systems. Our modular conveyors are designed to fit effortlessly into your current operational setup, ensuring a smooth transition with minimal disruption.

- Seamless System Compatibility: Our conveyors are compatible with a wide range of existing logistics equipment and software systems. This compatibility is crucial for ensuring a cohesive and efficient workflow.

- Minimal Operational Disruption: When integrating our conveyors, we focus on minimising downtime. Our installation process is quick and efficient, designed to integrate with your operations without significant disruptions.

- Ease of Integration: Our team works closely with you to ensure the integration process is smooth and tailored to your specific needs. We understand the importance of maintaining operational continuity and strive to make the integration as seamless as possible.

- Enhanced System Efficiency: Post-integration, our conveyors work in tandem with your existing systems, enhancing overall efficiency. This synergy between new and existing systems elevates the productivity and effectiveness of your operations.

Long-Term Benefits and ROI

Investing in L-A-C Logistics Automation’s modular conveyor systems brings substantial long-term financial and operational benefits. These systems are a strategic investment, yielding a significant return on investment (ROI) over time.

The financial benefits stem from increased efficiency and reduced labour costs. Our conveyors automate processes, leading to faster throughput and fewer errors, which translates to cost savings. Over time, these savings accumulate, often surpassing the initial investment.

In terms of operations, the adaptability of our systems means they stay relevant and efficient as your business evolves. This longevity and flexibility eliminate the need for frequent replacements or upgrades, contributing to long-term savings.

Customers have reported a noticeable impact on their bottom line within a relatively short period post-installation. The ROI is not just in tangible financial terms but also in operational efficiency and the ability to adapt to future market changes.

Thus, the value of investing in our conveyor systems extends well beyond immediate operational improvements, laying a foundation for sustained growth and profitability.

Conclusion

In conclusion, choosing L-A-C Logistics Automation for your conveyor module needs ensures you benefit from a system that is adaptable, scalable, and seamlessly integrated into your existing operations.

Our solutions are designed to provide long-term financial and operational advantages, demonstrating a clear return on investment.

Contact us for more detailed information or to schedule a consultation. Discover how our innovative conveyor solutions can transform your fulfilment centre’s efficiency and productivity.