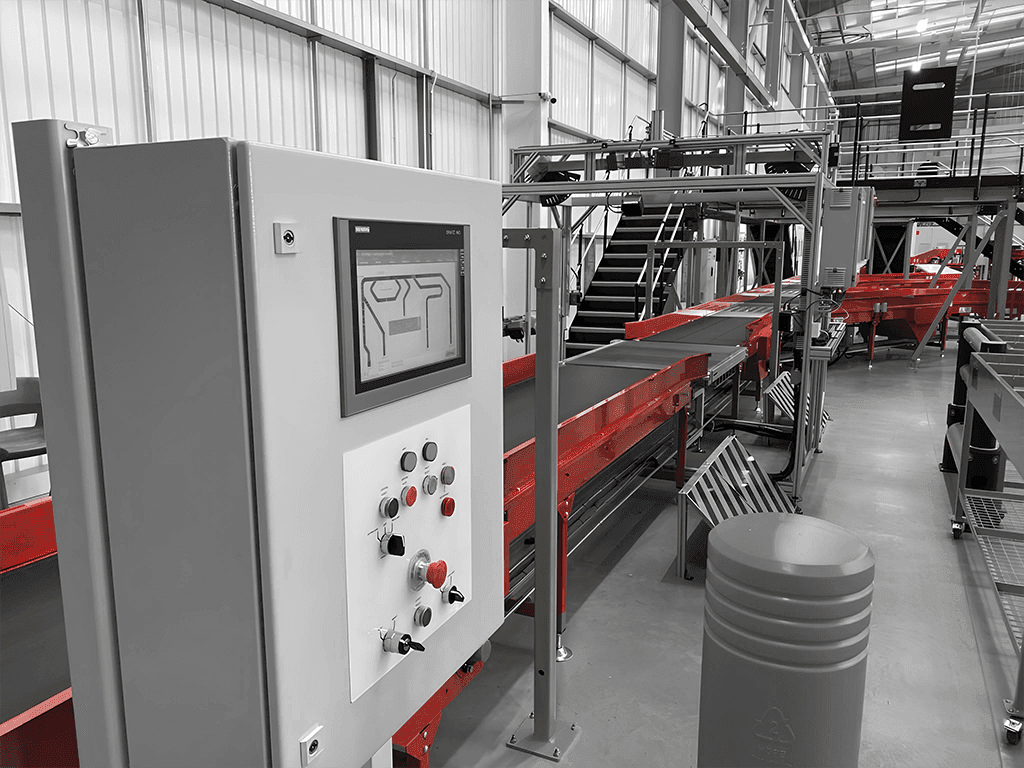

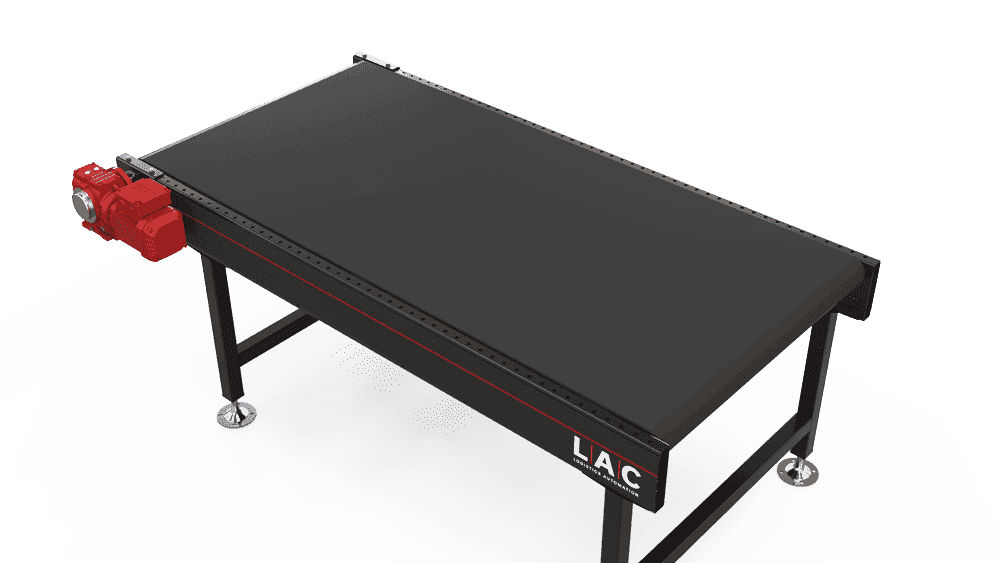

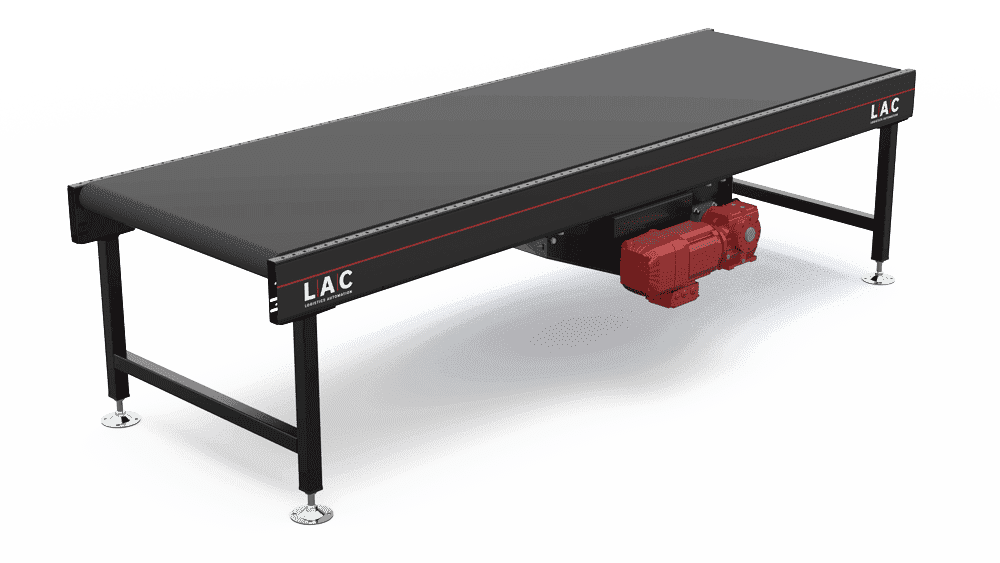

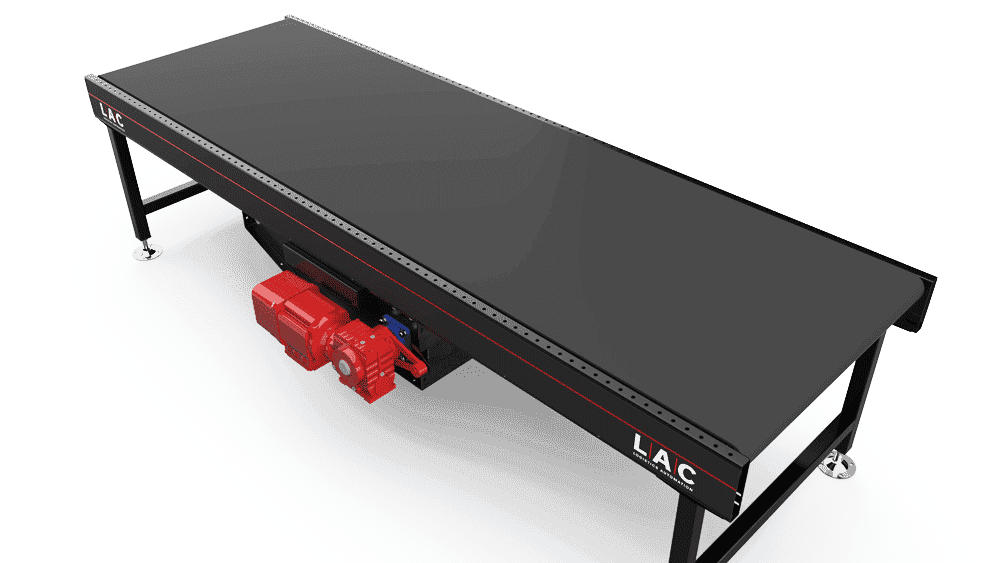

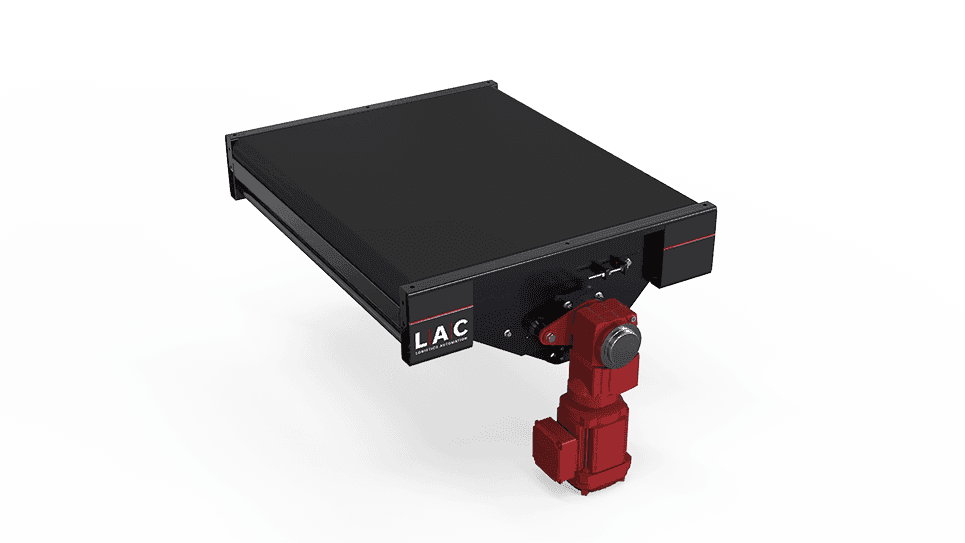

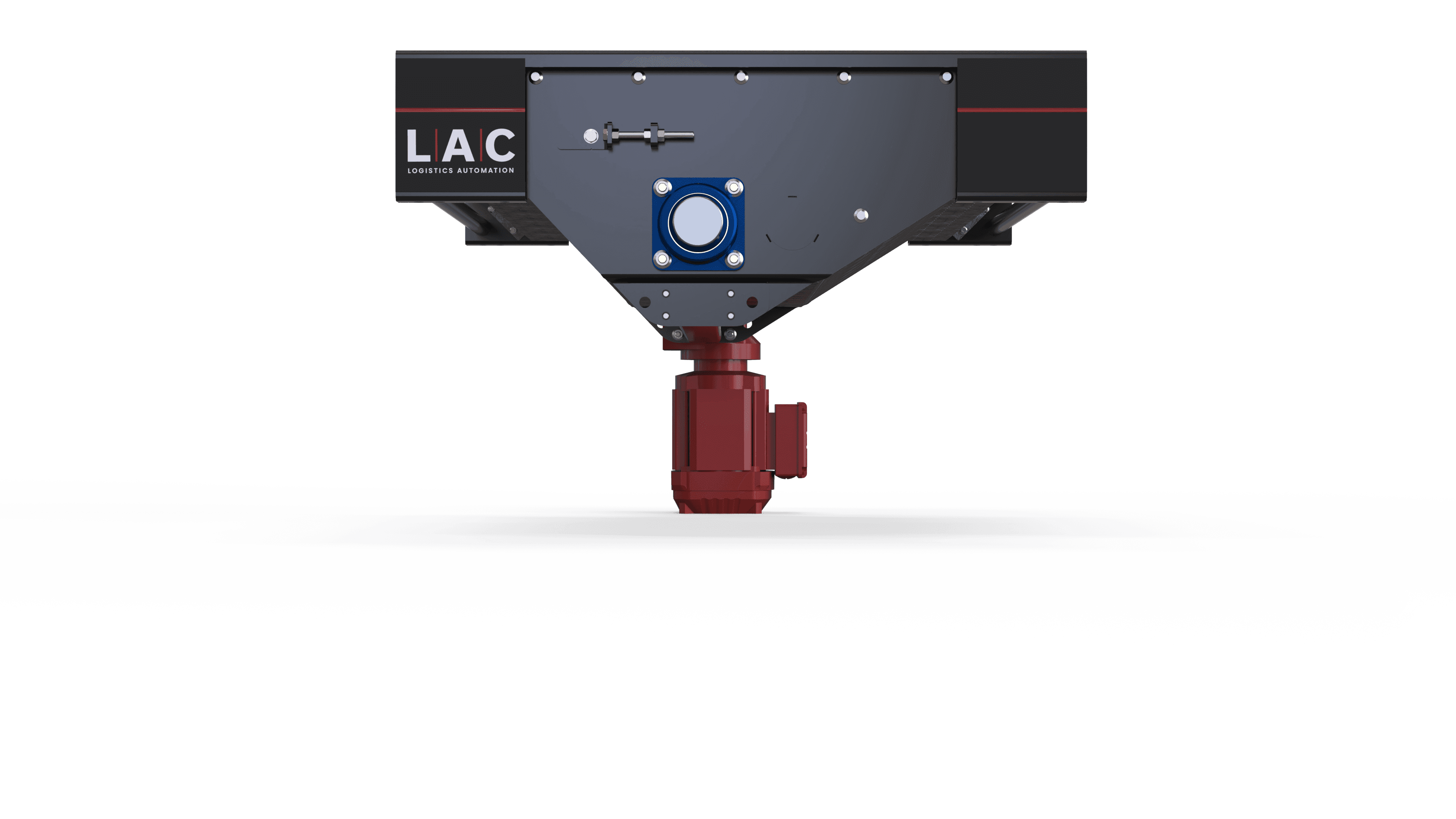

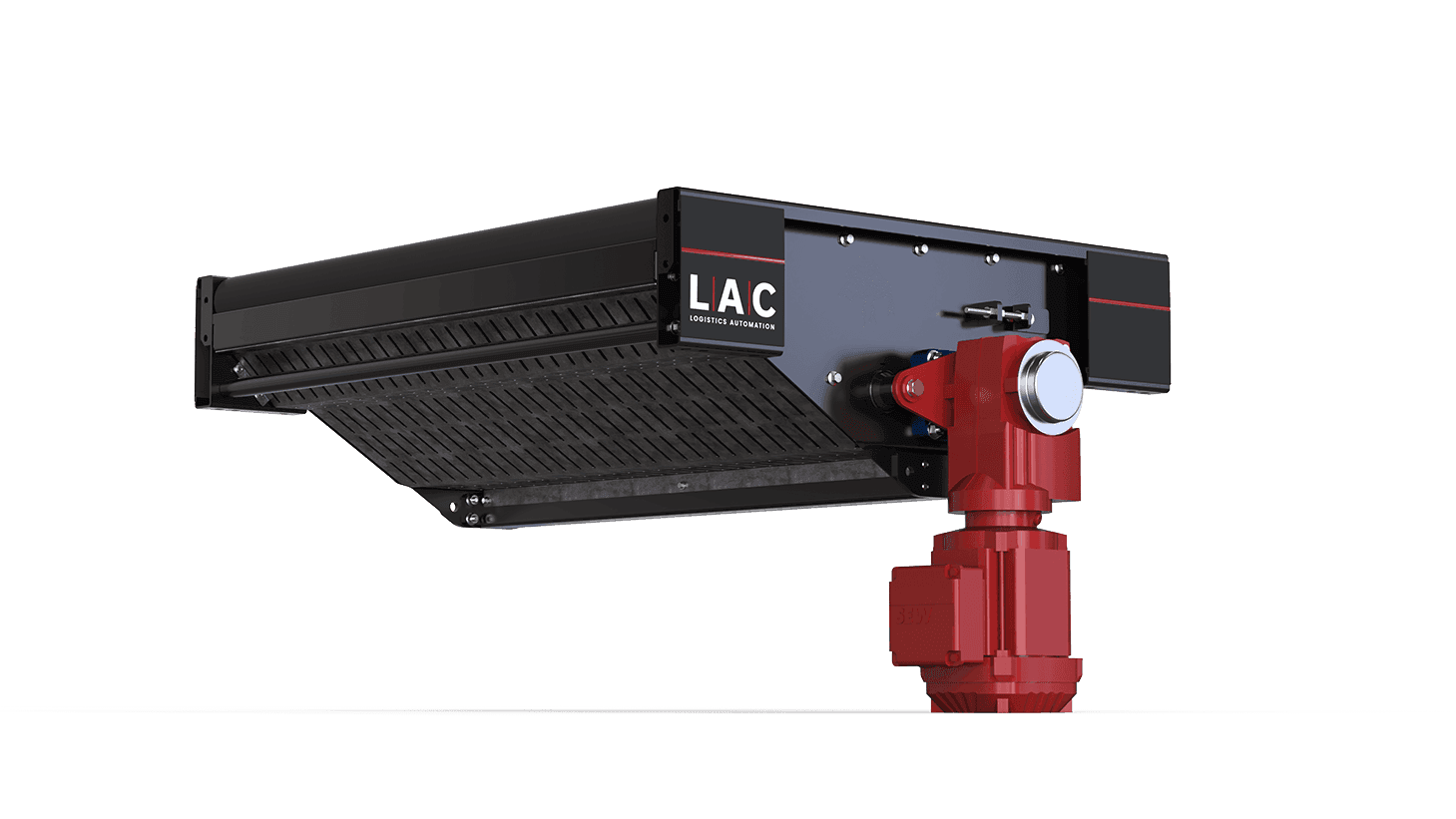

End-driven belt conveyors are a practical and efficient way to transport a variety of products. With the drive motor located at the end of the conveyor, these systems offer a space-saving design. With its robust construction and ease of maintenance, end-driven belt conveyors are a more cost-effective solution.

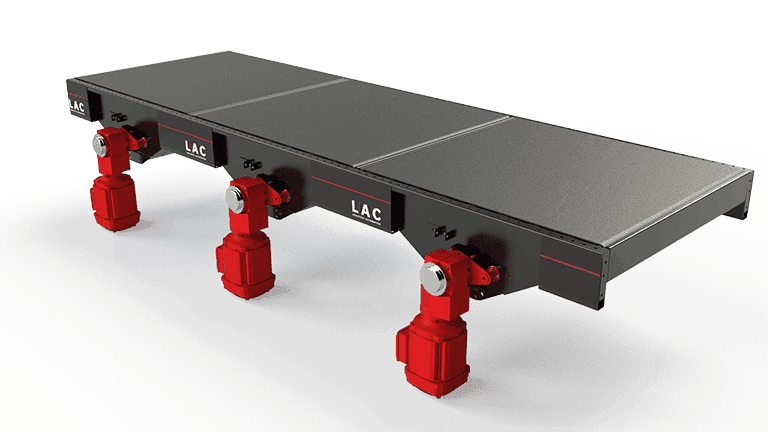

ALL THE BELT CONVEYORS WE PRODUCE ARE DIFFERENT FROM THE NEXT:

We have a comprehensive range of drive and bed types available, subject to the load to be conveyed and the conveyor speed. You can see one of our recent articles on 3 ways belt conveyors can be used today.

Our standard conveyor belt would be a PVC; however, for specialist applications, we have thousands of conveyor belts to choose from. Our experienced sales engineers are able to specify which will be the most suitable for each application and what would best suit your business needs. As a leading belt conveyor manufacturer, we pride ourselves on offering a wide variety of belt materials, including rubber conveyor belts for industrial applications.