Get an Accurate Understanding

Before you can start improving the efficiency of your warehouse conveyor system, you first need to have an accurate understanding of its operational requirements and challenges. Working with a trusted andexperienced partner with expertise in identifying, designing and delivering robust systems shall enable you to deliver your business objectives.

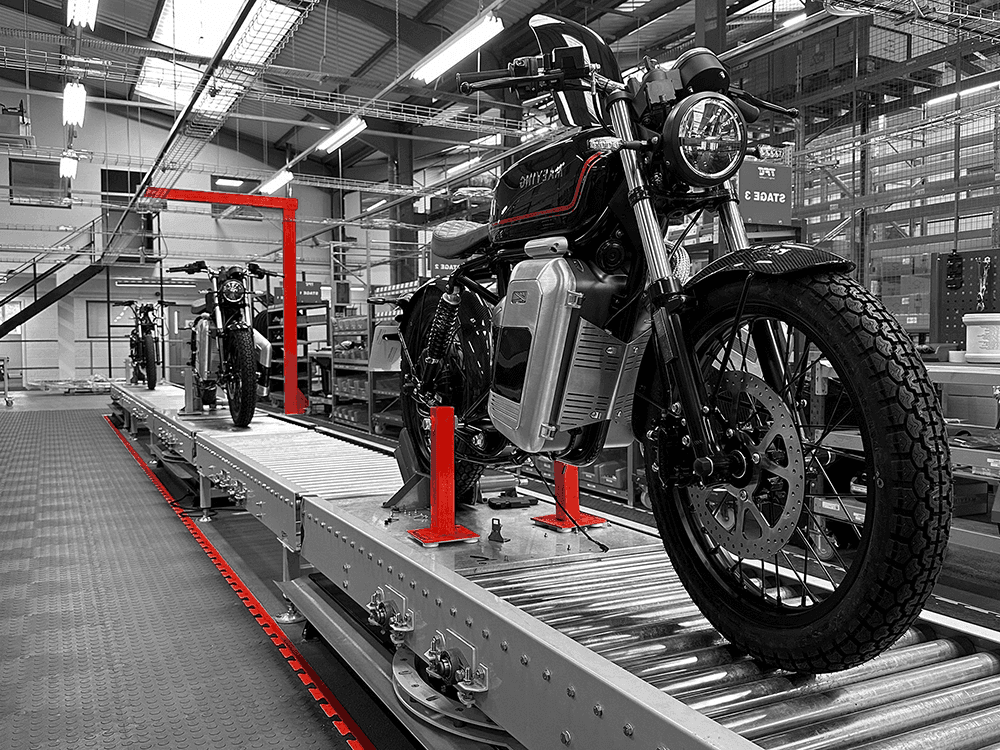

Once you have this information, you can start making some changes to the system that will improve its efficiency. One of the most important changes you can make is to the conveyor belts themselves. By choosing and selecting the right combination of technologies to suit warehouse functions, you can improve the efficiency of the system. It involves selecting the right belt type, material, and speed to create an effective & fast network of conveyor systems.

Another change you can make is to the way the items are transported. You can change the layout of the warehouse, or you can use more automated systems to move the items. Optimising warehouse layout and networks improves operational performance, saves costs, reduces labour, and allows you to process more goods in the same space.

By making these changes, you will be able to improve the efficiency of the conveyor systems in your warehouse and increase the output of your business.

Optimise Your Conveyor System

One of the most important things you can do to improve the efficiency of your warehouse conveyor system is to optimise it. By doing this, you can reduce the time it takes to move products from the warehouse to the sales floor and increase the overall throughput of your operation.

There are a few different ways you can optimise your system;

Choose the right conveyor system

The type of conveyor system you choose will affect the way products move through your warehouse. For example, a belt conveyor system is more efficient than a chain conveyor system, but a chain conveyor system is more efficient than a belt conveyor system if the product is heavy.

Choose the right material

Some materials move faster than others. For example, plastic products move faster than metal products. You can use this information to your advantage by organising your products by material.

Choose the right dimensions

You can also optimise your system by choosing the right dimensions. For example, you may want to increase the width of a conveyor belt if it’s too narrow.

Choose the right speed

You also can optimise the speed of your conveyor system by choosing the right speed. For example, you may want to slow down the speed of a belt conveyor if it’s too fast.

Choose the right guard

You also can optimise your system by choosing the right guard. For example, you may want to install a guard to keep products from moving off the conveyor belt.

Design Efficient Equipment

One way to improve the efficiency of warehouse conveyor systems is to design efficient equipment. This means choosing the right type of conveyor belt, the right size of belt, and the right number of belts. For example, you might need one belt for small items and one belt for large items.

It’s also important to choose the right combination of subsystems and components to achieve an overall smooth flow of material. Efficient system design with high optimisation followed by simulation further helps identify risks and scope of improvement and deliver a high–performing conveyor system that fits exactly your intralogistics requirements.

Control and Monitor Your Conveyor System

Conveyors are an important part of warehouse operations, but if they’re not managed correctly, they can cause a lot of wasted time and resources. To improve the efficiency of your conveyor system, you need to control and monitor it closely.

Firstly, you need to know how much product your conveyor system is capable of moving. This is important because you won’t waste time and resources moving products your conveyor system isn’t capable of handling.

Secondly, you need to have a system in place to track the status of your conveyor system. This includes things like the weight of the product on the conveyor belt, the number of items in the belt, and the speed of the belt. Various technologies like dimensioning weighing and scanning, diverters, sorters and mergers can be deployed in the system design to suit traffic management, and provide visibility and accuracy thereby elevating overall performance

Finally, you need to have a system in place to troubleshoot any issues that may occur with your conveyor system. This includes things like belt breakdowns, broken parts, and product jams. By having a system in place to track, monitor, and troubleshoot your conveyor system, you’ll be able to optimise its efficiency and save time and resources.

Use Intelligent Guidance and Control Software

Warehouse conveyor systems play a very important role in the efficient operation of a business. They help to move goods from one place to another and they can be very helpful in increasing the speed of a business. Using intelligent guidance and control software can help you to keep track of the location of all the goods in your warehouse and it can also help you to control the speed of the conveyor system.

Other ways you can improve the efficiency of your warehouse conveyor systems include;

- Installing sensors on the conveyor belts can help you to monitor their condition and detect problems early.

- Using remote monitoring and control is a great way to keep track of your warehouse from anywhere in the world.

- Using automatic sorting is another great way to improve the speed of your warehouse and reduce the amount of time that you have to spend sorting the goods.

- Using robot pallets as they are controlled by a robot and they are great for moving heavy goods. They are also very reliable and they can help to reduce the amount of time that you have to spend moving the goods.

Thank you for reading our blog, we hope you enjoyed it. By following the above tips, you will be able to improve the flow of goods and reduce the amount of time that it takes to get your products to the customer. For your warehouse conveyor systems needs, get in contact with us at L-A-C Logistics Automation today!