Creating a Detailed Brief to Ensure Installation Satisfaction

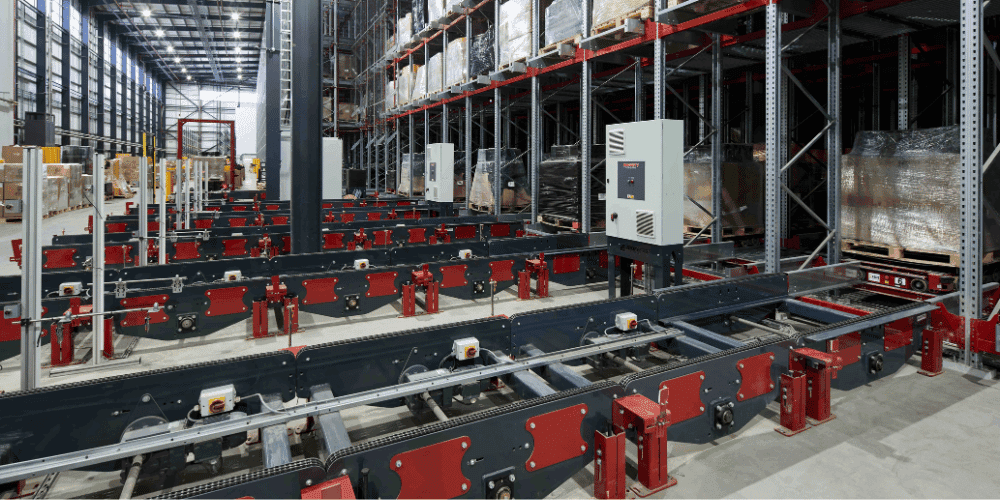

When you need new conveyors for your warehouse or workplace, an initial understanding of the installation is needed. Therefore, the key to the success of a project can be the creation of a good brief. In other words, the more detailed a brief that is created, the better we can understand exactly what it is you are looking for from your installation. Once we have received an in-depth brief from the customer, our team at L-A-C Logistics Automation can work on how to fulfil your conveyor needs best.

What Do You Need to Consider Including in Your Brief?

- The weight of the product you are moving.

- The dimensions of the product.

- The size of the available floor space for the system.

- CAD drawing or drawing of the floor space.

- The height of the building where the system will be installed. This is key to understanding space in this modern world is valuable. There may be an opportunity to build upwards relieving lower space for other operations.

- The required cycle time/system throughput.

- Is the system fully automated? Are certain areas required to be left for manual interaction/non–driven sections?

- The material and load capacity of the flooring where the system will be sited.