L-A-C Portfolio of 24V Conveyors and Modules

Our wide range of re-engineered conveyor modules shines a light on operational and energy efficiency with a host of robust modules and accessories to seamlessly integrate with the conveyor solution design to offer unrivalled material handling excellence.

The Poly-O Straight Conveyor has a robust construction of zinc-plated rollers ideal for gentle product handling. The Poly-O straight conveyor minimises product impact and optimises operational flow, providing a seamless solution for zero-line pressure and standard transportation of goods for a wide range of industries. The Stainless Poly-O Straight Conveyor is further enhanced with the durability and resilience of stainless-steel framing, well-suited for demanding operations or those where hygiene is critical.

The Poly-V Straight Conveyor features multiple V-shaped ribs fitted along the belt to provide additional structure for heavy-duty applications needing a reliable and more stable journey when transporting larger items.

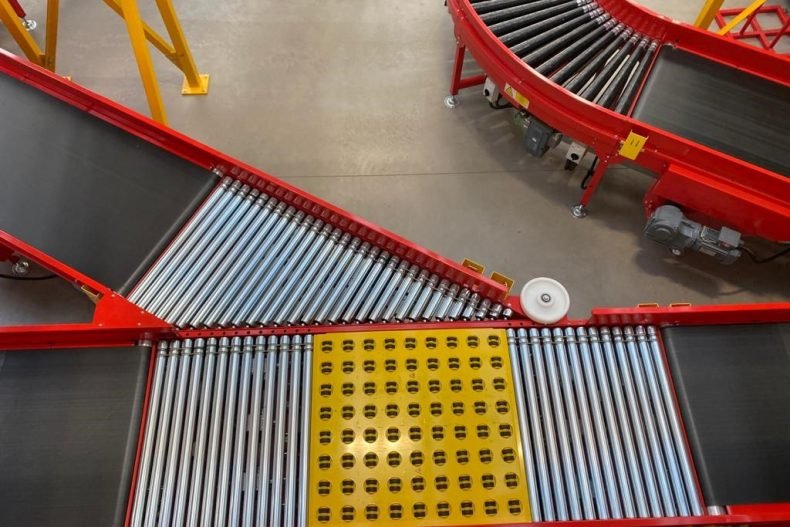

Conveyor Modules for Additional Integration

Conveyor systems are often designed with combinations of many different conveyor modules, all playing a part in the overall efficiency of material handling. Here are just some of the key conveyor modules that enhance standard and straight-line conveyors to optimise efficiency across operations:

Aligner conveyor: Used to align products in a specific direction, ideal for applications where the next process requires items to be presented in a certain way, such as labelling.

Merge conveyor: This conveyor module is designed to merge multiple lines into one or more primary lines, often used in post and parcel sortation.

Lift-up gate: An innovative piece of conveyor technology, a lift-up gate allows for safe and quick human access through conveyor lines without the need for a bridge or steps. This saves time and prevents the risk of injury, without impacting material handling speed.

Switch sorter: Switch sorters are used to change the direction of product flow without reducing the speed or volume of throughput. This helps with space optimisation as conveyor lines can be sent in different directions quickly and efficiently.

24V bend: These conveyor modules are widely used in distribution, manufacturing, and packaging operations, where curved or bend sections are necessary to route products efficiently.

Transfer pop-up: This highly versatile piece of conveyor technology consists of a belt that ‘pops up’ between the rollers, allowing the flow of products to rotate by 90 degrees.