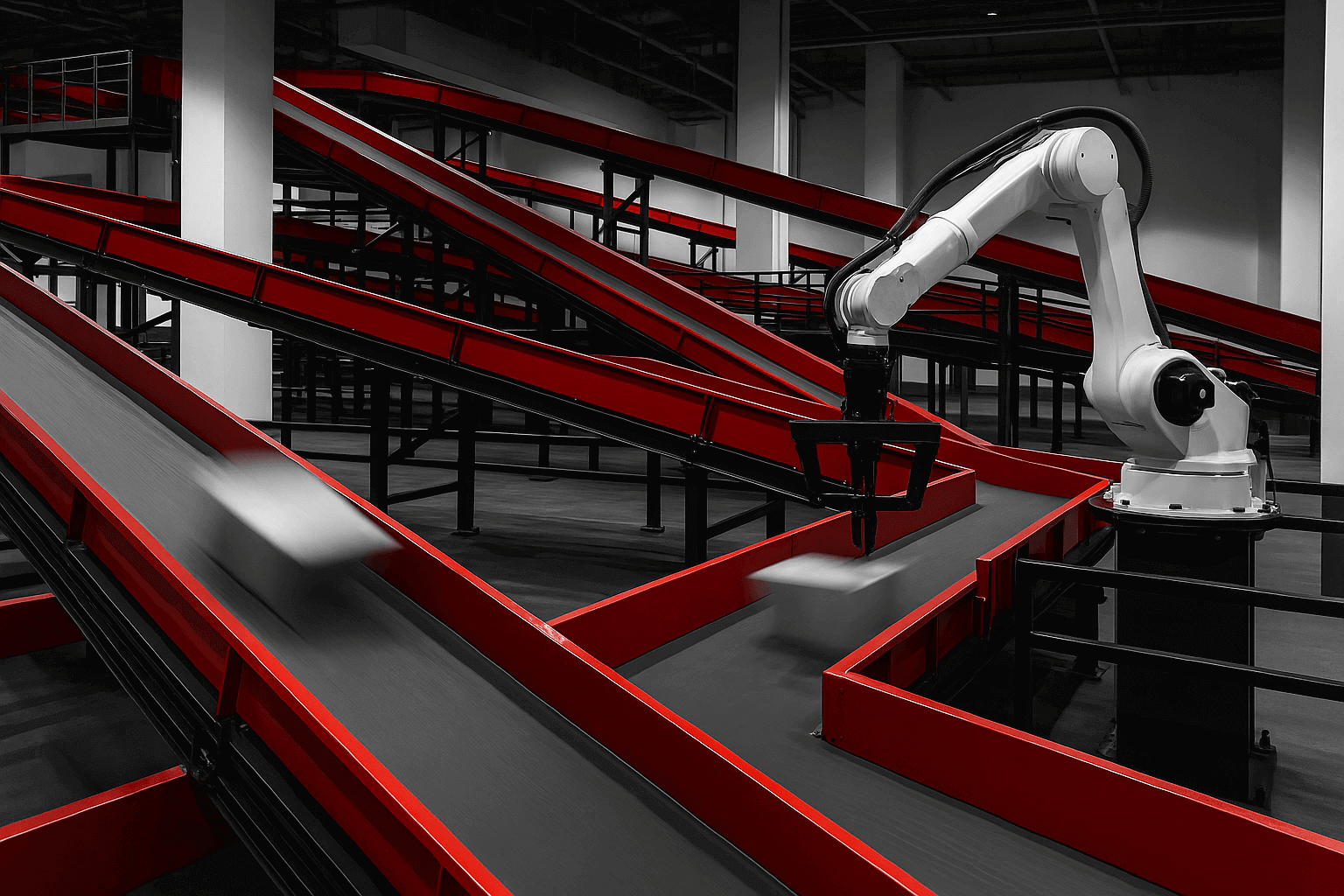

Types of Conveyors in Order Processing

Order processing is often fast and furious, relying on the right automated conveyor systems to ensure a consistent flow of goods. The choice of conveyor depends on the industry and the type of product being handled, examples of which include:

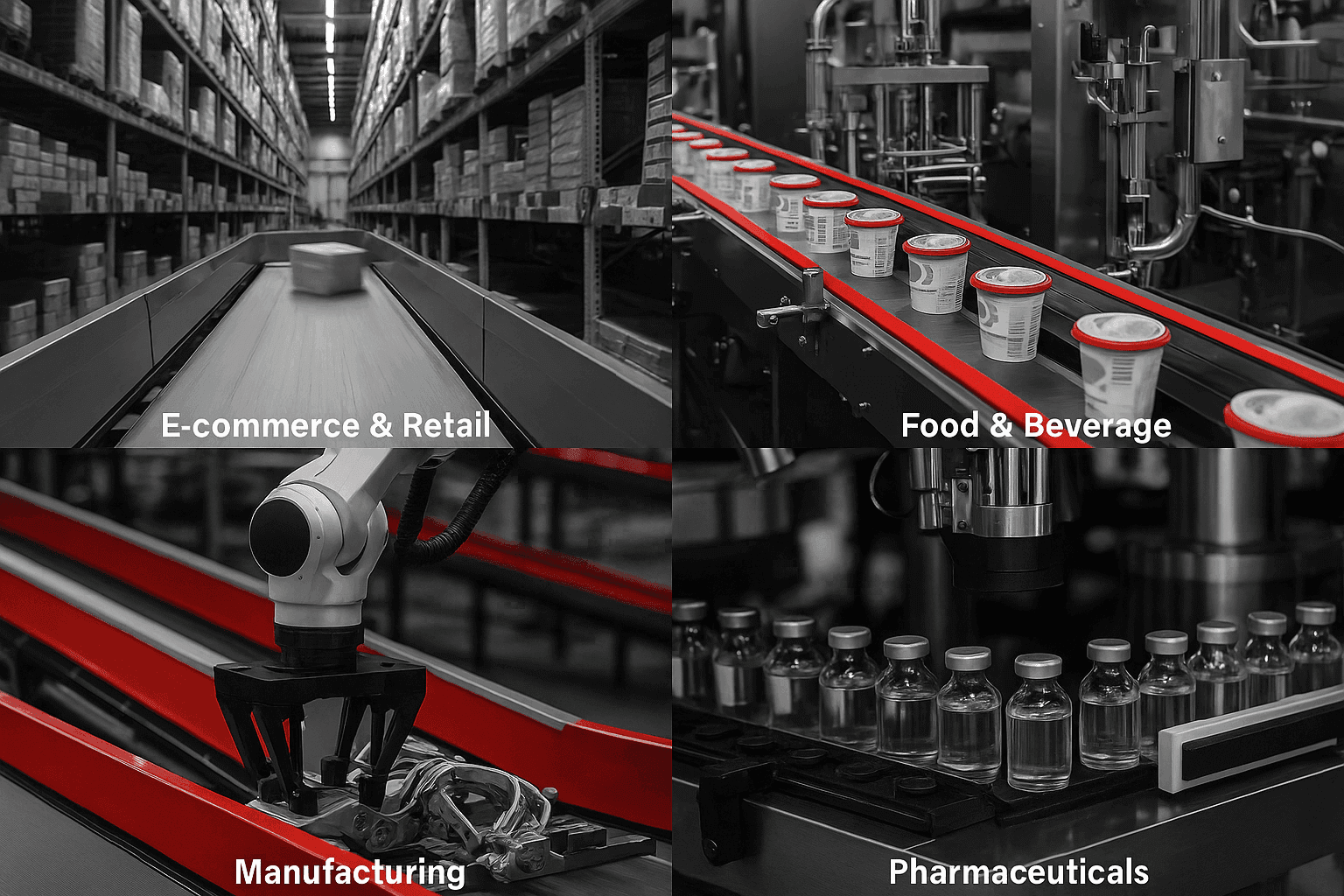

Belt Conveyors – ideally suited for e-commerce and retail, handling parcels of different shapes and sizes smoothly and efficiently.

Roller Conveyors – both gravity and motor-driven chain or roller conveyors are widely used in distribution centres and manufacturing for transporting cartons and totes.

Modular Plastic Belt Conveyors – offer hygienic, easy-to-clean surfaces that make them ideal for food & beverage operations.

Spiral or Vertical Conveyors – enable vertical transport of goods in warehouses with limited floor space, ensuring continuous product flow between levels.

Overhead Conveyors – free up valuable floor space and are typically seen in garment retail and on manufacturing assembly lines.

Extendable or Boom Conveyors – particularly useful for truck loading and unloading in high-volume e-commerce operations.

Pharmaceutical-Grade Conveyors – designed for cleanroom environments, with stainless steel and easy-wash surfaces to ensure compliance with strict hygiene standards.