The Business Case for Automation

Manual palletising remains physically demanding and repetitive. Workers typically handle thousands of items per shift, leading to fatigue, reduced accuracy, and increased risk of musculoskeletal injuries. According to the Health and Safety Executive, handling, lifting, and carrying account for a significant proportion of workplace injuries reported annually in the UK.

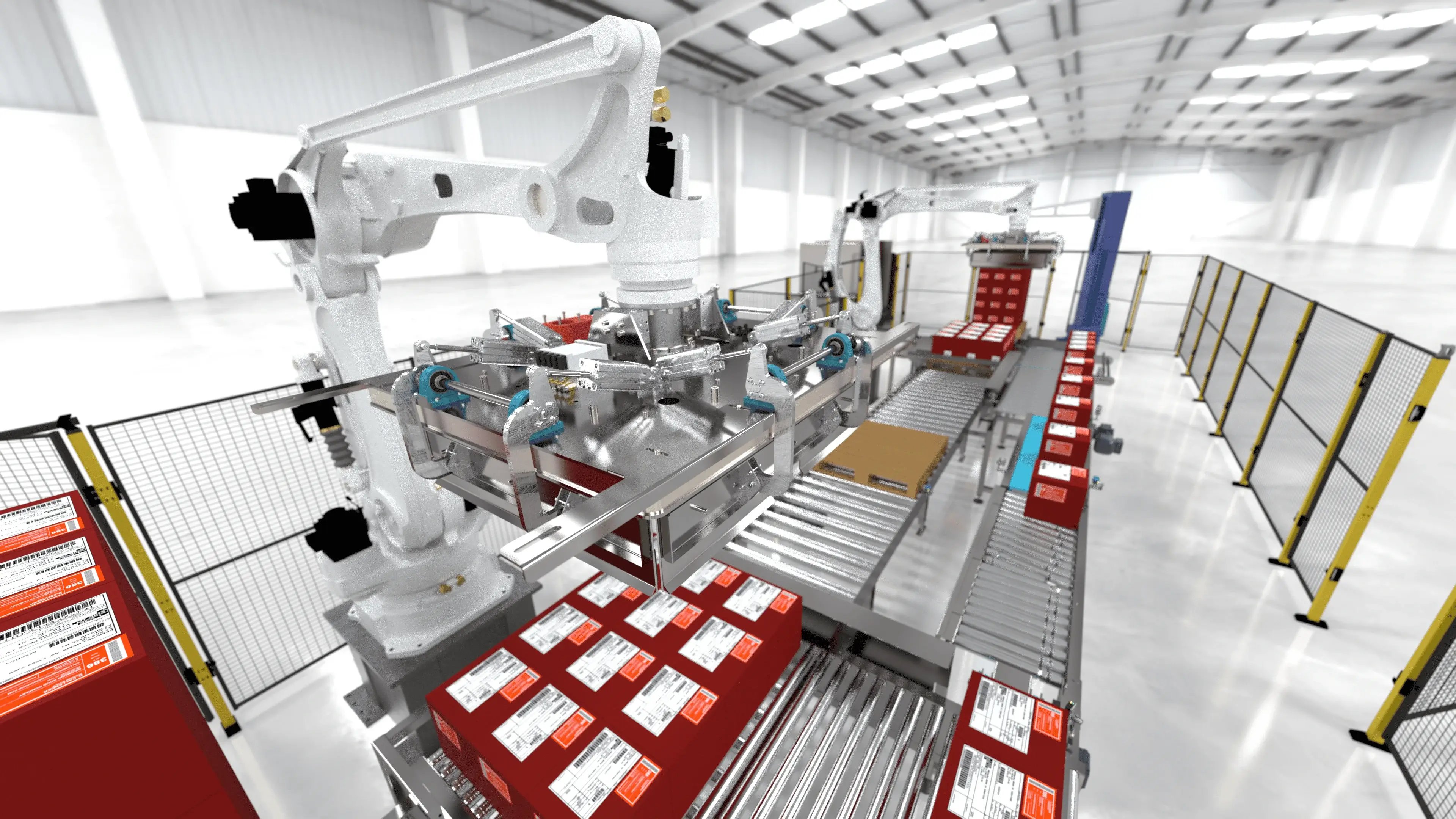

Robotic automation addresses these challenges whilst delivering measurable operational benefits. Consistency in pallet construction improves load stability during transit, reducing product damage and associated costs. Systems can operate continuously without breaks, increasing throughput during peak periods. Labour can be redeployed to higher-value tasks that require human judgement and problem-solving skills.

The return on investment varies by application, but many operations report payback periods of two to four years when factoring in labour savings, reduced product loss, and improved throughput.