Plastic Omnium recruited the expertise of L-A-C Logistics Automation to design, build, test, and install a wide belt conveyor system solution to solve their manual handling of moulds problem. Plastic Omnium is a global company whilst remaining an independent family-owned business, who are committed to delivering first-class products in the fast-moving and ever-changing automotive environment. […]

Hermes and L-A-C Logistics Automation have had a successful partnership over the last few years, giving Hermes assurance that LAC could deliver on a state-of-the-art return automation conveyor system. Hermes’ investment in L-A-C’s return automation conveyor system has already processed more than 6 million parcels in just a few months, thanks to the system’s ability […]

International Automotive Components (IAC) was excited by the punch system L-A-C proposed and with a strong track record of finesse completed projects, IAC was confident L-A-C were the team to deliver this innovative automation solution. “This servo-driven, punch and die tooling approach meant that the desired complex profile to be cut within the parts ensured […]

L-A-C has seen an extraordinary response from the logistics industry for its mobile line shaft conveyor with major parcel carriers such as Hermes, DPD, and DHL placing orders to bolster their increased business. Multiple parcel carriers use mobile line shaft conveyors within the depot network including DPD, Hermes, Yodel, Parcelforce, and DHL. Therefore, it was […]

L-A-C Logistics Automation working closely with long-standing partner Interroll have installed a full turnkey cross belt sorter system at a UK sorting facility of a leading courier provider, Skynet Worldwide Express. The vertical cross belt sorter can achieve sorting rates of 4,000 parcels per hour. Established in 1972, Skynet Worldwide Express has grown to become […]

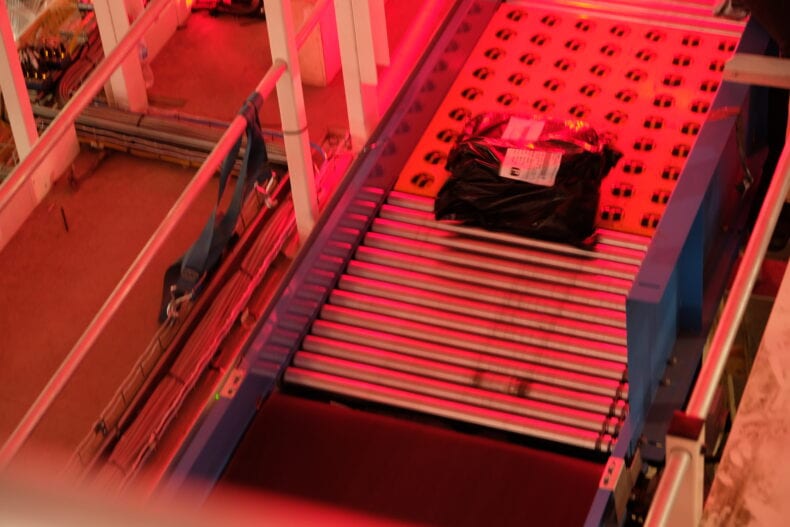

An international parcel delivery business turned to L-A-C to help solve their latest problem, after having successfully provided several roller and belt conveyor systems for other major international parcel delivery companies. Why a roller and belt conveyor system? The carrier had been experiencing an increase in traffic of out of gauge parcels sometimes referred to […]

With a vast array of conveyor system solutions at hand, L-A-C Logistics Automation are able to provide resolutions for all types of parcel handling conundrums. Why choose L-A-C Logistics Automation for your conveyor system solutions? By engaging with the client at the earliest stage possible our highly experienced sales team are able to reveal in […]

An industry leader in distribution and wholesale for automotive, maintenance and accessories and retail introduces powered roller conveyors for products of all sizes, shapes and weights. The products are picked from storage on either one of three floors and are required to be delivered to the ground floor packing and despatch area. Client profile The […]

L-A-C Logistics Automation impressed a Major Tier 1 Automotive Supplier working in collaboration with FSG Tool & Die, by producing an automotive automation bespoke interior trim punching machine. The machine delivers a clean and precise cut, that doesn’t mark and guarantees a repeatable performance. Motor vehicle manufacturers constantly refine and develop their product range this […]

The automation system is used to build and check for correct assembly of an automotive car door lever bowl unit to 100% accuracy. A major tier 1 supplier of automotive parts was thrilled with the new automation system that allowed Various parts are loaded by an operator and the machine checks colour, surface finish, correct […]