The UK logistics and warehouse industries are more crowded than ever. For customers, it can be difficult to decide upon the best suited system to meet their warehouse needs. Conveyor systems offer a range of benefits for a variety of required parcel handling, sortation, storage, and palletising solutions. At L-A-C Logistics Automation, we provide customers […]

The UK manufacturing industry is sometimes considered as a declining industry. However, the UK is currently the 9th largest manufacturing nation on the globe. It employs over 2.5 million people and has an annual output of almost £200 billion. Robot palletising is one of many solutions that can support the manufacturing industry. When used in […]

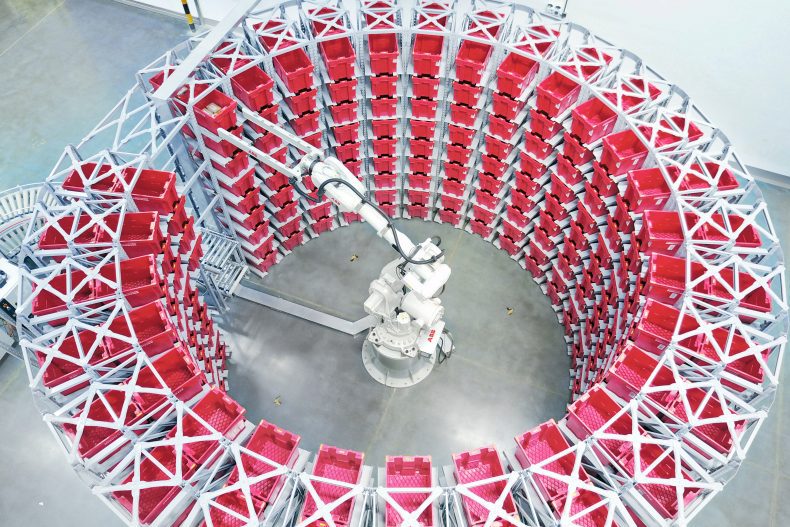

Who are ABB? ABB are a major global technology specialist, striving to transform societies and industries alike for a more productive, dynamic, and sustainable future. With a history stretching back more than 130 years, the ABB have always strived for greatness. Headquarters based in Zurich, Switzerland, they specialise in connecting leading software to robotics, therefore […]

A new fully automated bale handling solution has been installed to help Ball Beverage Packaging improve its efficiency and save money. The system replaced a near 20-year-old Kawasaki ZD130S robot at the Wakefield plant, bringing greater speed, precision and durability to the customer. When Ball Packaging needed a new, fully automated waste material conveying and […]

Allen Distribution, a third-party logistics company focused on grocery distribution, installed their first robotic warehouse automation solution provided by Prime Robotics. Founded in 1998, Allen Distribution offers warehouse and distribution services including food-grade warehousing, transportation services including asset-based equipment and company drivers. From their eight warehouse locations, the company serves groceries to clients of all […]

A global wine producer approached L-A-C to design a solution which would not only increase efficiency, but raise safety standards by eliminating the requirement for manual handling. L-A-C designed and developed an automated pallet de-stacker solution which de-stacks pallets at the rate of 80 pallets per hour but also has the functionality for the settings […]

L-A-C Logistics Automation have released to market a robotic pick and place packaging cell aimed at the fresh food industry. The cell has the flexibility to handle a complete range of film lidded trays and punnet materials. The latest cell is designed to deliver a packing rate of 120 punnets per minute and is configured […]

In response to a growing requirement for stainless steel tote and crate de-stackers within the food industry, warehousing, and distribution sectors, L-A-C Logistics Automation have developed a machine that performs not only to the rapid outputs that modern industries require but also ensures consistent and reliable delivery. Being made of a robust design, this tote […]

With extensive experience in the food industry, L-A-C were called upon by a well-known dairy company to supply a new stainless-steel belt conveyor system for an improved butter tub checking line. What did the belt conveyor system need to do? The customer realised that significant financial gains could be made on their existing sample check-weigh […]

L-A-C have teamed up once again with Intralox® to build a 3.5 meter-high Spiral Conveyor system incorporating Intralox’s patented DirectDrive™ System. Expertise Intralox recognises L-A-C’s experience and production capabilities as one of the few UK licensed installers of their patented Direct Drive System (DDS) for spiral conveyor system. Quality, trust, and teamwork ensure that both […]