Benefits of Automated Vertical Systems

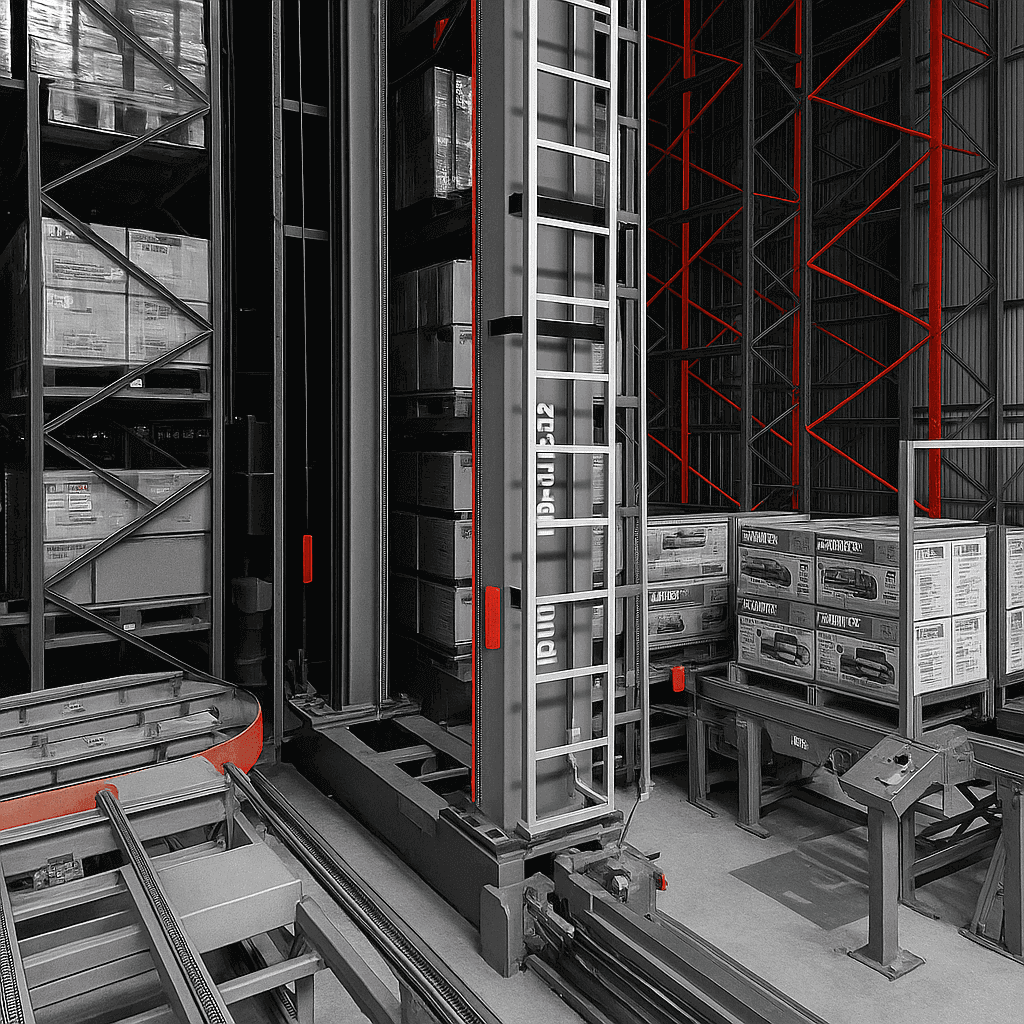

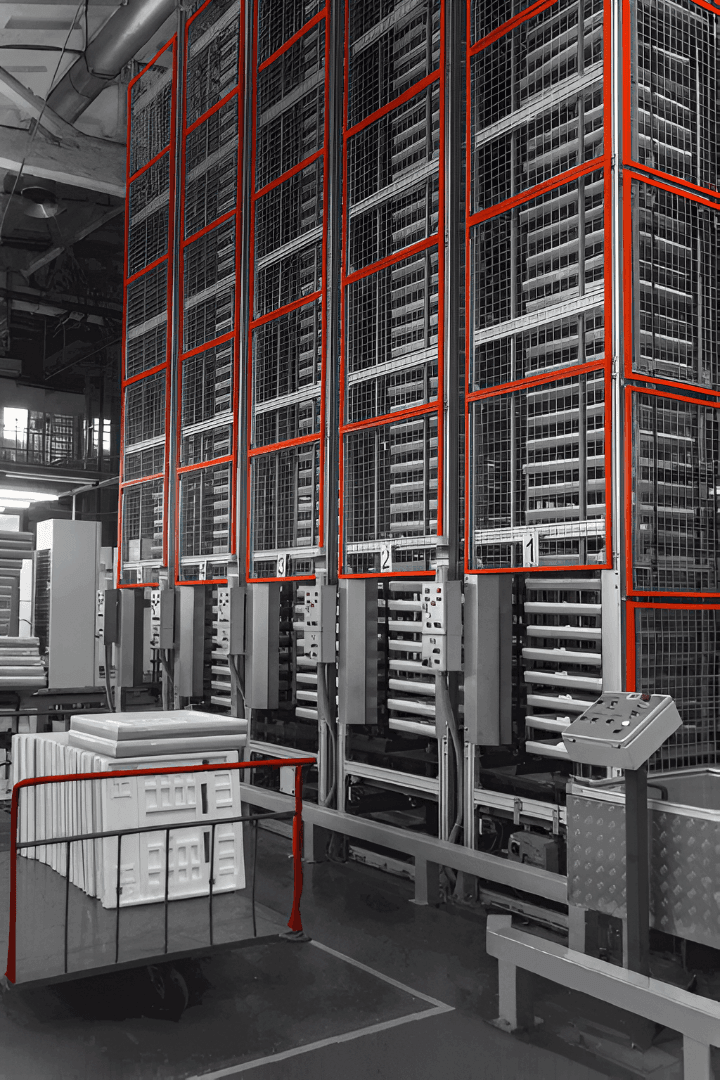

Maximising Space Utilisation

One of the most compelling advantages of Automated vertical storage systems is their ability to dramatically increase floor space capacity. Traditional shelving systems typically utilise only 25–30% of available cubic space, leaving much of the vertical storage underused. Automated vertical systems, by contrast, can reclaim up to 85% of storage space while using ceiling heights that would otherwise go to waste.

For logistic centers operating in urban areas where property costs are high, this efficiency translates directly into financial savings. Rather than expanding into larger premises, businesses can increase capacity within their existing footprint. Some organisations have reported doubling or even tripling their storage capability after implementing vertical automation.