Accelerating Picking Operations

The time warehouse staff spend walking between pick locations represents one of the largest inefficiencies in order fulfilment. Research indicates that in traditional warehouses, picking operatives can spend up to 70% of their shift simply travelling between storage spaces. Automated storage and retrieval fundamentally redesigns this workflow.

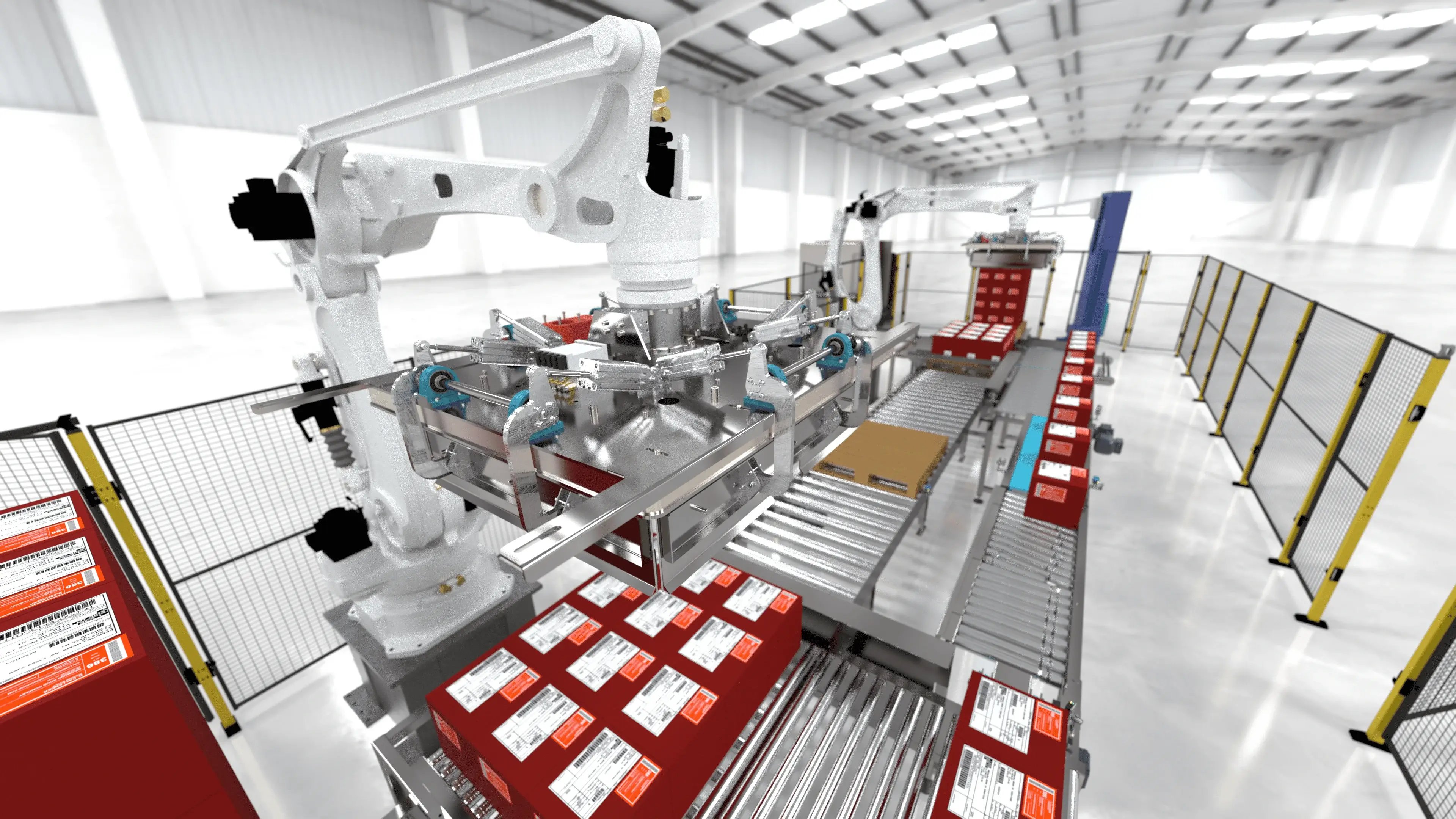

By bringing products directly to a fixed picking station, these systems eliminate unnecessary travel time. Operatives remain in an ergonomically optimised position whilst the system retrieves items in sequence, dramatically reducing pick times. Many warehouses report picking speed improvements of 200% to 300% following automation implementation using mobile robots, automated guided vehicles, or an autonomous mobile robot to assist in load carrier movement.

The consistency of automated retrieval systems also contributes to faster operations. Items are always delivered to the same ergonomic height and position, allowing pickers to develop muscle memory and work more efficiently. There is no variation in pick location, no searching through disorganised shelves, and no uncertainty about item locations.

Reducing Picking Errors

Automated shelving systems incorporate digital displays and guidance systems that direct operatives to the exact item needed for each order. Light-directed picking, where LEDs illuminate the correct compartment and display the required quantity, reduces picking errors by up to 67% compared to paper-based methods.

This accuracy improvement has cascading benefits. Fewer errors mean reduced returns processing, less time spent on order corrections, and improved customer satisfaction. The financial impact of eliminating even a small percentage of picking errors can be substantial, particularly for operations handling thousands of orders daily across main aisles or overhead conveyors.

Optimising Inventory Management

Beyond immediate space and speed benefits, automated shelving systems provide enhanced inventory visibility. Integrated warehouse management systems and warehouse control systems track every item movement, creating real-time inventory data that improves stock accuracy and supports better purchasing decisions. Warehouse managers gain precise insights into stock levels, turnover rates, and storage lane utilisation patterns.

This data enables more strategic slotting decisions, where fast-moving items are positioned for even quicker retrieval whilst slower-moving stock occupies less accessible locations. The automated storage and retrieval system can automatically reorganise storage positions based on demand patterns, continuously optimising picking aisles and workflow efficiency without manual intervention.